Formwork in Civil Engineering

What is formwork in civil engineering? The term refers to the creation of temporary moulds in which you then pour concrete for it to be formed. In this article, we will look at what role formwork has played in civil engineering and how it continues to make great buildings possible.

While many of the iconic structures remaining from ancient times were fashioned from bricks and mortar, there can be no doubt that the introduction of concrete marked a revolution that has transformed the construction process for the last two millennia. What the future may hold remains a matter for speculation but, for the moment, it appears that this composite of Portland cement, aggregate, and water, and the means to shape it will remain the mainstay of modern construction, and formwork will continue to play a vital role in civil engineering.

Although many of us may marvel at modern landmarks, such as The Shard in London and the Burj Al Arab Hotel in Dubai, the achievements of the world’s civil engineers are often less appreciated. Be it a luxury hotel or a massive hydroelectric dam, in each case, the architects and builders rely on the unique properties of this miracle mix first used around 8 000 years ago by desert dwellers to create underground cisterns for storing water. They would have used wooden shuttering to hold the sides of these structures in place while the concrete cured, in place of the more versatile formwork products used in civil engineering projects today.

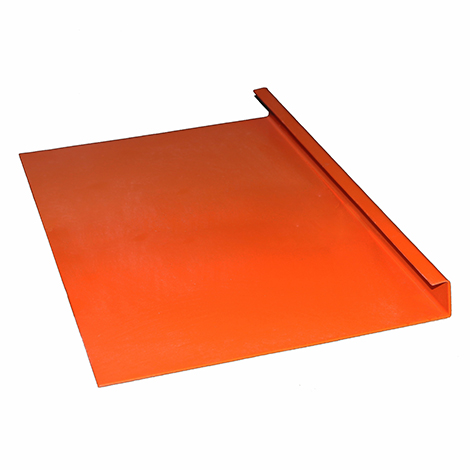

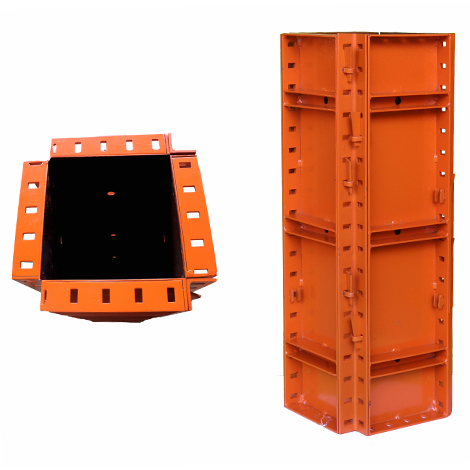

That said, many small builders still favour wooden shuttering because it is cheap and relatively easy to make. However, metal components are far more durable and offer a highly versatile option, allowing architects and builders more scope for innovative planning and construction. While private construction companies are generally responsible for building our homes, office blocks, and shopping centres, others provide highways, airports, railways, and other essential infrastructure.

The residents of Manhattan Island can thank specialists skilled in the use of formwork in civil engineering for the 21 bridges that connect them to the surrounding New York boroughs. The same is true of the passengers who travel on the more recently constructed subways that now use prefabricated sections of reinforced concrete lining to provide improved support.

The ease of preparing, transporting, and pouring concrete is its greatest strength and the reason it has become the world’s most widely used building material. However, without an effective means to mould it, it would be used only as flooring, and the practical applications for formwork in civil engineering would be minimal.

To meet the needs of builders in all construction sectors, manufacturers must provide moulds that are durable and easy to assemble and maintain, offering both standard sizes and shapes and bespoke designs built to the client’s specifications. Disc-O-Scaff is a local manufacturer that ticks all of these boxes and is a supplier of world-class formwork for use in civil engineering and many other construction applications. View all our formwork products here.