How to Use Beam Slab Formwork for Effective Construction?

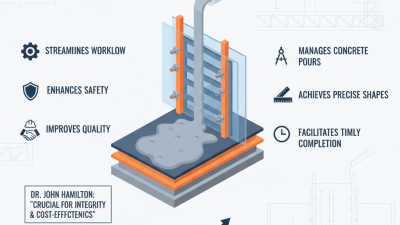

In the realm of construction, the efficiency of beam slab formwork is indispensable. Industry reports indicate that effective use of formwork can reduce project time by up to 30%. Yet, many still overlook best practices. According to John Smith, a leading expert in construction technology, “Beam slab formwork, when utilized correctly, provides unmatched structural stability.”

Despite its benefits, challenges remain. Skilled labor shortages and improper training can lead to inefficiencies. Many contractors are unaware of the latest materials that enhance formwork performance. Incorporating innovative solutions and techniques can make a significant difference. Adaptation in training programs is crucial, reflecting a persistent area for improvement.

Beam slab formwork systems must be analyzed for both advantages and limitations. Keeping an open mind to different techniques can yield improved outcomes. The success of any construction project is often defined in these subtle details. Further research is essential to stay updated on the evolving practices in this field.

Understanding Beam Slab Formwork: An Overview of Its Importance

Beam slab formwork plays a crucial role in modern construction. It provides the necessary support and shape for concrete structures. This type of formwork is essential for achieving optimal strength and stability. According to industry reports, the use of beam slab formwork can increase construction efficiency by up to 30%. This is significant for project timelines and cost management.

However, implementing beam slab formwork is not without challenges. Proper design and execution are vital. Miscalculations in load-bearing capacity can lead to serious safety issues. Research indicates that inadequate formwork design contributes to 15% of structural failures. Inadequate training and oversight can exacerbate these mistakes. Therefore, it’s essential for teams to adhere to best practices during installation.

Attention to detail is key when using beam slab formwork. Quality materials and precise alignment are fundamental. Neglecting these factors can lead to defects in the final structure. Regular inspections and adjustments are necessary throughout the process. Effective construction relies on the seamless interaction between formwork and concrete placement. This synergy ultimately defines the strength and durability of the finished product.

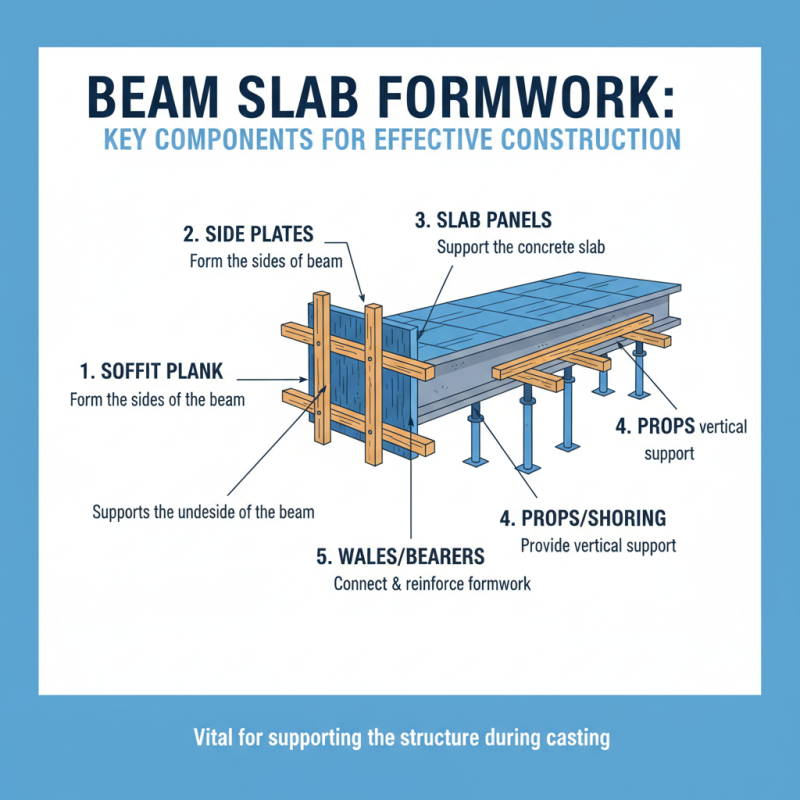

Key Components of Beam Slab Formwork System and Their Functions

Beam slab formwork is critical for effective construction. It consists of several key components. Each plays a vital role in supporting the structure during the casting process.

The main component is the beams. They support the weight of the slabs as they cure. Then there are the form panels. These panels shape the concrete and ensure a smooth finish. It is essential to properly align these panels. Misalignment can lead to structural issues later. The braces provide stability to the entire system. They prevent any unwanted movement during the setting phase.

Be careful with the materials used. Quality can vary widely, which affects the final result. Regular inspections can help identify weak points. Ensure that all components are secure before pouring concrete. Construction often involves trial and error. Learning from mistakes is part of the process. Aim for precision, but accept that imperfect conditions may arise.

Step-by-Step Guide to Setting Up Beam Slab Formwork Efficiently

Setting up beam slab formwork is crucial for a strong construction foundation. Start by gathering all necessary materials. Ensure you have enough formwork panels and supports. Incorrect spacing can lead to structural issues. Make sure the panels align correctly. Misalignment can cause uneven surfaces.

Next, establish the framework for the beam. Use sturdy scaffolding to support the formwork. This is vital for safety. Double-check the height measurements. Inaccurate heights may create complications later. Pay attention to the beam's thickness. It must meet structural requirements.

Finally, secure the formwork properly. Use clamps or ties as needed. An unstable formwork can lead to dangerous situations. Inspect for any weaknesses. This step is often overlooked. A careful check can prevent future problems. Remember that every construction site is unique. Adapting methods to fit your project may be necessary.

Best Practices for Maintaining Safety During Beam Slab Formwork

When using beam slab formwork, safety should be a top priority. This type of work involves heavy materials and complex structures. Workers must be aware of their environment and potential hazards. It’s crucial to establish a safety protocol before starting. Regular safety training sessions can help employees understand risks. Ensure everyone knows what to do in an emergency.

Tip: Always wear appropriate safety gear, including helmets and gloves. Keep a first aid kit nearby. Remember, accidents can happen even with experienced workers. Therefore, vigilance is key. Communication is essential on a construction site. Teams should use hand signals or radios to stay connected. Misunderstandings can lead to dangerous situations.

Another aspect to consider is the stability of the formwork itself. Sometimes, workers may overlook the importance of proper installation. Inspect supports and connections continuously. Small mistakes can lead to significant problems. It’s important to reflect on past errors and learn from them. Regularly assess the work area and the equipment used, adjusting as necessary to maintain safety.

Common Challenges and Solutions in Using Beam Slab Formwork

When using beam slab formwork, challenges often arise. Misalignment is a common issue. It can lead to structural flaws and increased costs. Workers may rush and skip essential checks. This might yield uneven surfaces.

Tip: Use laser leveling tools to ensure precise alignment. Regular inspections during installation can also help.

Another challenge involves the weight of materials. Heavy components can strain workers. They may tire quickly, impacting the workflow. It's crucial to handle these materials safely. Improper lifting techniques can lead to injuries.

Tip: Organize training sessions to educate workers on proper handling. Introducing lighter alternative materials could also alleviate stress.

Weather conditions might create complications as well. Rain can damage formwork, while extreme heat affects curing time. These factors can delay your project.

Tip: Have a weather plan. Use tarps to protect formwork from rain. For heat, consider wetting the forms intermittently. Adjusting your approach can improve outcomes and mitigate challenges.

Related Posts

-

How to Choose the Right Precast Concrete Formwork for Your Project

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

Top Benefits of Using Bendy Formwork in Modern Construction?

-

Why Bulkhead Formwork is Essential for Successful Construction Projects

-

What is Plastic Construction Formwork and Its Benefits in Modern Building Projects?

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects