Top 10 Things You Should Know About Formwork for Construction Projects

When it comes to construction projects, one of the key elements that can significantly impact the overall efficiency and quality of work is the use of formwork. Understanding the essential aspects related to formwork is crucial for builders, contractors, and project managers alike. This article will delve into the top ten things you should know about formwork, highlighting its importance, types, and best practices.

Formwork, which acts as a temporary structural support system for pouring concrete, plays a pivotal role in ensuring that the final structure meets engineering standards and design specifications. Knowing the best practices and innovative techniques about formwork can lead not only to better construction outcomes but also to cost-effectiveness and enhanced safety on-site. As we explore these critical insights, it becomes clear that having a firm grasp of what to consider about formwork will empower construction professionals to make informed decisions that drive projects toward success.

Understanding the Basics of Formwork in Construction

Formwork is a crucial component in construction that serves as a temporary or permanent mold for shaped concrete. Understanding the basics of formwork involves recognizing its various types, including traditional timber, pre-cast concrete, and modern plastic or metal systems. Each type offers unique advantages based on the project's specific needs, such as cost, speed of installation, and the complexity of the design. Familiarity with these formwork systems can help construction managers make informed decisions that adhere to budget and timeline constraints while ensuring high structural quality.

Moreover, safety is a paramount concern in formwork construction. Proper installation and maintenance of formwork systems are essential to prevent accidents and ensure the integrity of the concrete structure. Workers must be trained to handle and assemble these systems correctly, and regular inspections should be conducted to identify any potential hazards. By prioritizing safety and understanding the foundational principles of formwork, teams can improve efficiency and foster a more productive construction environment.

Top 10 Things You Should Know About Formwork for Construction Projects - Understanding the Basics of Formwork in Construction

| Item | Description | Material Type | Cost Estimate ($/sq ft) | Common Applications |

|---|---|---|---|---|

| 1 | Traditional Wood Formwork | Wood | 1.50 | Residential and Commercial Slabs |

| 2 | Steel Formwork | Steel | 2.75 | High-rise Buildings |

| 3 | Plastic Formwork | Plastic | 2.00 | Small Projects |

| 4 | Aluminum Formwork | Aluminum | 3.00 | Multi-story Buildings |

| 5 | Fabric Formwork | Textiles | Variable | Curved Structures |

| 6 | Insulated Concrete Formwork (ICF) | Foam | 4.00 | Energy-efficient Buildings |

| 7 | Plyform | Plywood | 1.80 | Foundations |

| 8 | Wall Panels | Concrete | 3.50 | Vertical Structures |

| 9 | Reusable Formwork | Metal/Plastic | 2.50 | Various types of buildings |

| 10 | Self-raising Formwork | Manual/Electric | 5.00 | High-rise construction |

Types of Formwork: Choosing the Right Option for Your Project

Choosing the right type of formwork is crucial for the success of your construction project. There are several options available, each with its own set of advantages and disadvantages that can significantly impact efficiency, cost, and safety. Traditional timber formwork is often celebrated for its adaptability and ease of use; however, it can require more labor and time to set up. In contrast, steel and aluminum formwork systems offer durability and reusability, which can lead to lower overall costs on larger projects, despite a higher initial investment.

Another option to consider is modular formwork, which allows for quicker assembly and disassembly, making it ideal for projects with tight deadlines. For projects involving complicated shapes or curves, specialized formwork systems may be necessary, providing flexibility without compromising structural integrity. Additionally, the choice between pre-fabricated and site-built formwork can affect timelines and labor needs. Ultimately, selecting the appropriate type of formwork boils down to project specifications, budget constraints, and the level of skill available on-site. Careful evaluation of these factors will help ensure that your formwork supports the project efficiently and safely.

Top 10 Types of Formwork for Construction Projects

This chart displays the popularity and usage of different types of formwork used in construction projects. The data is based on industry standards and trends.

Key Materials Used in Formwork Construction

Formwork is a crucial component in construction projects, providing the temporary structure needed to shape and support concrete until it gains sufficient strength to stand independently. Understanding the key materials used in formwork construction is essential for ensuring the durability and effectiveness of the project. One of the most common materials is plywood, which is favored for its versatility and cost-effectiveness. It can be molded into various shapes, making it suitable for complex designs while offering adequate strength to withstand the pressure of wet concrete.

Another prominent material is steel, known for its robustness and longevity. Steel formwork is often used in larger projects due to its ability to maintain structural integrity under heavy loads. It is reusable and can be customized for different applications, which makes it a sustainable choice in the long run. Additionally, aluminum formwork has gained popularity owing to its lightweight nature and ease of handling. It allows for quicker installation and reduces labor costs, making it an appealing option for many contractors. Each material brings unique benefits to the table, and selecting the right one depends on the specific requirements of the construction project at hand.

Safety Considerations When Using Formwork

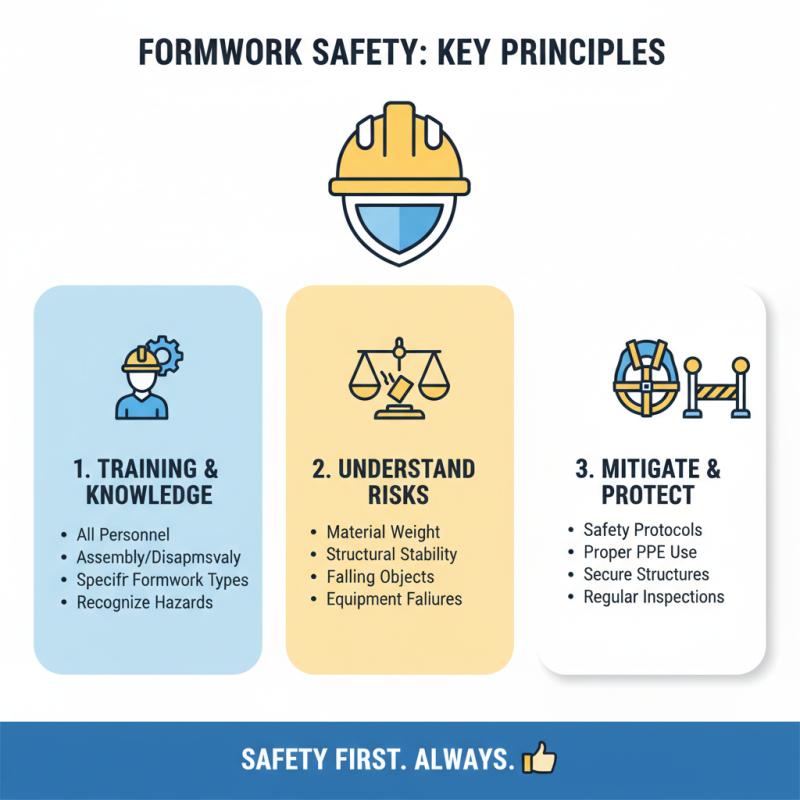

When using formwork in construction projects, safety considerations are paramount. Proper training for all personnel involved in the assembly and disassembly of formwork systems is essential. Workers must be familiar with the specific types of formwork being used and understand the potential hazards associated with each. This includes recognizing the weight of the materials, the stability of the structures being created, and the necessary safety protocols to mitigate risks such as falling objects or equipment failures.

Additionally, regular inspections of formwork should be conducted to ensure it is in good condition and properly supported. This not only prevents accidents but also maintains the integrity of the construction project. Safety gear, including hard hats, gloves, and harnesses, should always be worn by workers on-site. Implementing clear communication protocols can further enhance safety during the use of formwork, ensuring that all team members are aware of ongoing activities and any immediate hazards. By prioritizing these safety measures, construction projects can significantly reduce the likelihood of accidents and ensure a smoother workflow.

Maintenance and Inspection of Formwork Systems

Maintenance and inspection of formwork systems are critical components in ensuring the safety and efficiency of construction projects. According to the Occupational Safety and Health Administration (OSHA), improper maintenance and inspection protocols can lead to structural failures, resulting in costly delays and potential injuries on site. A comprehensive maintenance schedule should include regular checks for signs of wear and tear, as well as any damage to the formwork components. It is recommended that formwork systems be inspected daily before use, as this can dramatically reduce the risk of accidents and improve overall project outcomes.

Additionally, industry studies highlight that buildings constructed with properly maintained and monitored formwork systems can achieve a productivity increase of up to 30%. This emphasizes the importance of not only regular inspections but also effective training for workers who handle the formwork. When crews are knowledgeable about what to look for during inspections, they are better equipped to identify potential issues early. In fact, the American Society of Civil Engineers (ASCE) notes that up to 20% of construction costs can be attributed to rework from inadequate formwork practices. Therefore, prioritizing maintenance and inspections is not only a safety measure but also an economically sound strategy for construction companies aiming to improve their bottom line.