What is Plastic Construction Formwork and Its Benefits in Modern Building Projects?

Plastic construction formwork has emerged as a revolutionary solution in modern building projects, offering a range of benefits that traditional materials simply cannot match. As the construction industry continues to evolve, the need for more sustainable, efficient, and cost-effective solutions has become increasingly apparent. Plastic construction formwork stands out as an innovative alternative that not only enhances the quality of construction but also streamlines the building process.

One of the primary advantages of plastic construction formwork is its lightweight nature, which allows for easier handling and installation. This translates to reduced labor costs and a faster construction timeline. Additionally, plastic formwork is highly durable and resistant to moisture, making it an ideal choice for various weather conditions and reducing the risk of damage that can commonly occur with traditional materials. Furthermore, plastic construction formwork is reusable and recyclable, aligning with the industry's growing emphasis on sustainability and environmental responsibility.

In an era where efficiency and sustainability are paramount, the adoption of plastic construction formwork is indicative of a broader trend towards modernization in building practices. By integrating this innovative material, construction projects can achieve superior quality results while minimizing their ecological footprint, ultimately leading to a more sustainable future for the industry.

What is Plastic Construction Formwork?

Plastic construction formwork is an innovative alternative to traditional materials used in the construction industry, such as wood or metal. Made from high-density polyethylene and other durable plastics, this formwork system is specially designed to shape and support concrete structures during the curing process. Its lightweight nature makes it easy to handle and install, significantly reducing labor and transportation costs on job sites.

One of the primary advantages of plastic formwork is its resistance to water, chemicals, and corrosion, which ensures a long service life even in harsh conditions. Additionally, it is reusable, making it an environmentally friendly option that contributes to waste reduction in construction projects. The smooth surface of plastic formwork results in a higher quality finish on the concrete, minimizing the need for extensive post-construction treatments. As the industry moves toward more sustainable building practices, plastic construction formwork stands out as a forward-thinking solution that aligns with modern project requirements.

Types of Plastic Formwork Systems Used in Construction

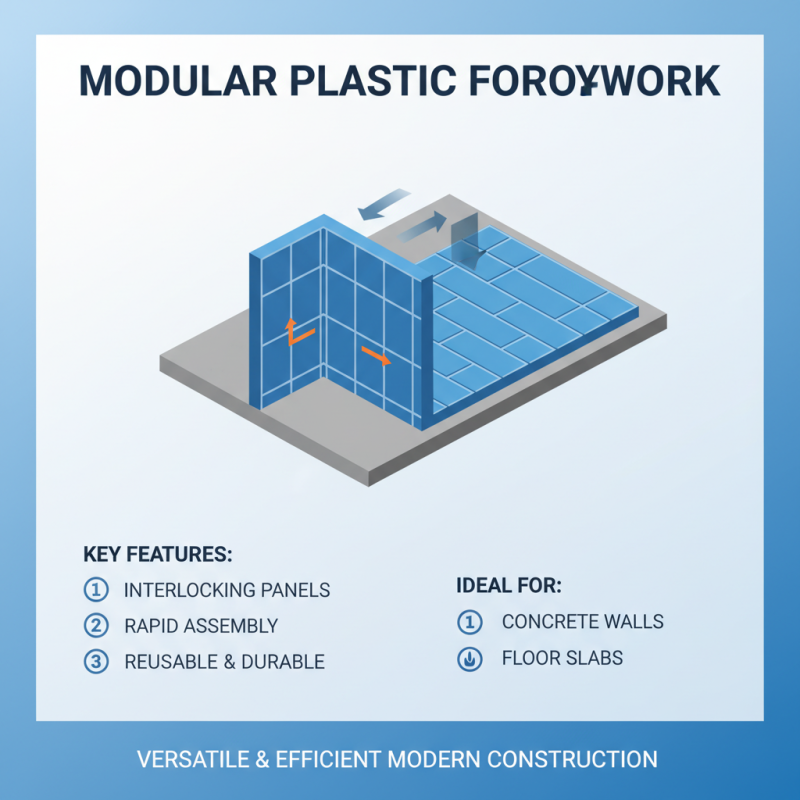

Plastic formwork systems are increasingly recognized in modern construction for their versatility and efficiency. These systems are primarily categorized into several types, each catering to different requirements of building projects. One popular type is the modular plastic formwork, which consists of interlocking panels that can be easily assembled and disassembled. This system is ideal for creating walls and slabs, as it allows for rapid deployment and can accommodate various shapes and sizes.

Another notable type is the reusable plastic formwork, designed for multiple projects. This system is lightweight yet durable, making it easy to transport and handle on-site. Its resistance to moisture and chemical exposure makes it an excellent choice for harsh construction environments. Additionally, there are specialized plastic formwork systems tailored for specific applications, such as column or beam construction. These options provide precise dimensions and finishes, ensuring structural integrity while reducing labor costs. The diversity of plastic formwork systems enhances productivity, making them a valuable asset in contemporary construction practices.

Key Benefits of Using Plastic Formwork in Modern Building Projects

Plastic construction formwork is rapidly gaining traction in modern building projects due to its numerous advantages over traditional materials. One of the key benefits is its lightweight nature, which allows for easier handling and reduced labor costs. This not only speeds up the construction process but also minimizes the physical strain on workers. Moreover, plastic formwork is resistant to moisture and chemicals, ensuring durability and longevity in various environmental conditions.

In addition to its practicality, plastic formwork promotes sustainability in construction. Many plastic products are made from recycled materials, and their reusable nature significantly reduces waste. As plastic formwork can be used repeatedly for multiple projects, contractors can lower their overall resource consumption, which is an important consideration in today’s eco-conscious building practices.

Tips: When considering plastic formwork, ensure to evaluate the specific project's requirements, such as the type of concrete used and the desired finish. This will help in selecting the right formwork system that aligns with your project goals. Another tip is to engage with experienced crews who understand the nuances of working with plastic materials, as their expertise can lead to efficient installation and optimal results.

Comparative Analysis: Plastic Formwork vs. Traditional Materials

Plastic construction formwork has emerged as a significant alternative to traditional materials like wood and metal in modern building projects. One of the primary advantages of plastic formwork is its lightweight nature, which not only makes it easier to handle and transport but also reduces labor costs on-site. Unlike traditional materials that can absorb water or suffer from corrosion, plastic formwork is resistant to moisture, ensuring greater durability and a longer lifespan. This resistance contributes to fewer maintenance requirements, allowing construction teams to focus more on the project at hand rather than the upkeep of their materials.

When comparing plastic formwork to traditional materials, it’s essential to recognize the environmental considerations as well. Plastic formwork can often be reused multiple times, leading to lower resource consumption over the project's lifecycle. In contrast, wooden formwork typically requires cutting down trees, which presents sustainability challenges. Additionally, plastic materials can be recycled at the end of their life cycle, promoting a circular economy.

**Tips:** When considering formwork options for construction, evaluate the project size and scope. For smaller projects, lightweight plastic formwork may lead to significant labor savings and efficiency. Always ensure that any formwork choice aligns with local building regulations and sustainability goals for a responsible approach to modern construction.

What is Plastic Construction Formwork and Its Benefits in Modern Building Projects? - Comparative Analysis: Plastic Formwork vs. Traditional Materials

| Aspect | Plastic Formwork | Traditional Materials |

|---|---|---|

| Weight | Lightweight | Heavy |

| Ease of Installation | Easy to handle and assemble | Requires skilled labor |

| Durability | High resistance to weathering | Susceptible to rot and corrosion |

| Reusability | Can be reused multiple times | Limited reusability |

| Cost | Higher initial cost, lower lifetime cost | Lower initial cost, higher maintenance |

| Environmental Impact | Recyclable and eco-friendly options | Less recyclable, higher environmental burden |

Sustainability and Environmental Impact of Plastic Formwork Solutions

Plastic construction formwork presents a forward-thinking solution to the challenges of sustainability in the construction industry. Traditionally, concrete formwork has relied heavily on materials like wood and metal, which often contribute to deforestation and resource depletion. In contrast, plastic formwork systems are typically made from recycled materials, significantly reducing the demand for new resources. This shift not only lessens environmental strain but also promotes the circular economy by giving new life to materials that might otherwise end up in landfills.

Furthermore, the lightweight nature of plastic formwork simplifies transport and assembly, resulting in reduced energy consumption during project execution. These systems are designed for reuse and longevity, which further minimizes waste over multiple construction projects. Their ability to withstand harsh weather conditions without deterioration ensures they remain viable over time, contributing to less frequent replacements and repairs. As construction continues to evolve, integrating sustainable practices like the use of plastic formwork is essential for minimizing environmental impact and fostering a more sustainable future for building projects.