Top Insights About Formwork in Construction Techniques?

Understanding formwork is crucial in construction. It serves as a temporary structure to support concrete until it sets. This technique not only shapes the concrete but also affects overall project efficiency. About formwork, several key insights can guide builders.

Modern materials play a vital role. Steel and plastic offer durability, but they come with higher costs. Wood remains popular but may not always be sustainable. Each choice has its pros and cons. Often, the balance between cost and quality requires careful thought.

Project managers must consider safety as well. Improper formwork can lead to accidents, risking workers’ lives. Reviewing design plans is essential, yet common oversights occur. Benefits arise from learning how formwork interacts with other elements in construction. Exploration can lead to innovative solutions, but challenges will always exist. Understanding and improving formwork processes is a journey.

Overview of Formwork in Construction Techniques

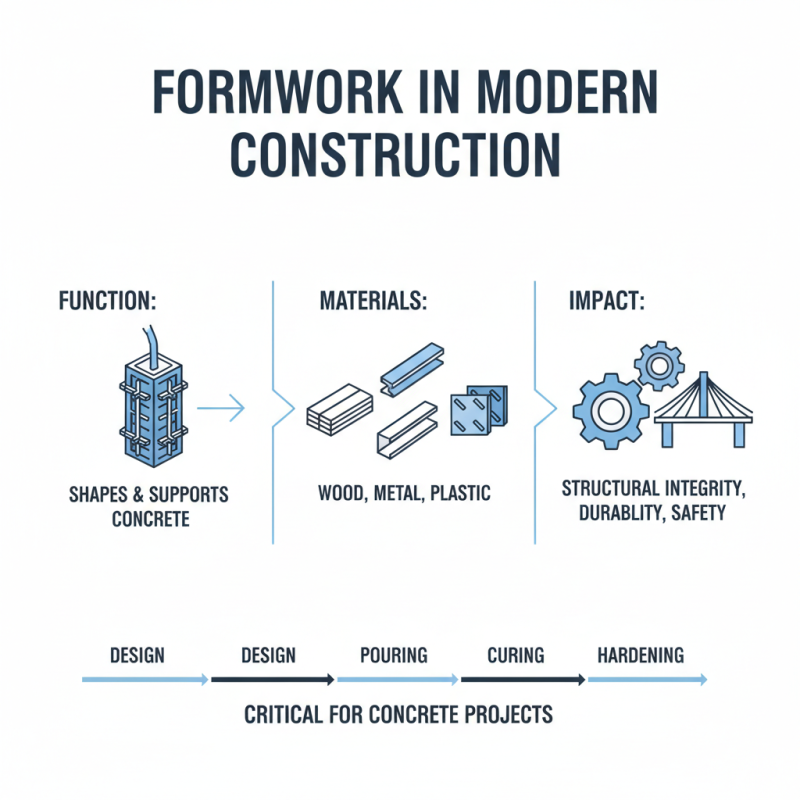

Formwork plays a critical role in modern construction techniques. It provides the shape and support for concrete until it cures and hardens. Typically made from materials like wood, metal, or plastic, formwork adapts to various project needs. Its design influences the overall structural integrity. Each choice can affect durability and safety.

One challenge in using formwork lies in the complexity of its assembly. Workers must be skilled to ensure accuracy. Poorly constructed formwork can lead to costly mistakes. Not every project follows a straightforward design, creating difficulties for the construction team. It's essential to evaluate and adjust plans as needed.

Sustainability is another aspect requiring attention. Traditional formwork can generate waste. Innovative techniques and materials offer solutions. Still, new methods need testing and refinement. Evaluating benefits and drawbacks is crucial. This careful balance of creativity and practicality defines effective formwork in construction today.

Types of Formwork Used in Modern Construction

Formwork plays a crucial role in modern construction. It supports concrete structures during pouring and curing. There are various types of formwork used today, each with its applications and benefits.

One popular type is traditional timber formwork. This method remains common for small projects. It is easy to work with but can be time-consuming to assemble. Prefabricated metal formwork is another option, ideal for larger projects. It allows for quick installation and reuse. However, initial costs can be high.

Tips: Consider the project's scale when choosing formwork. For smaller jobs, timber may suffice. Larger projects might benefit from metal systems. Always assess the environmental impact of materials. Some options may create more waste than others.

Another growing trend is the use of plastic formwork. It is lightweight and often reusable. According to the Global Construction Report, plastic formwork can reduce costs by up to 20%. However, it requires careful handling to avoid damage.

Each formwork type has advantages and drawbacks. Choices should reflect the project’s specific needs. Opting for the right formwork can significantly affect budget and timeline. Reflect on past projects for better decision-making.

Key Materials and Their Properties in Formwork

Formwork plays a crucial role in modern construction. It provides the molds that shape concrete structures. The choice of materials significantly affects the overall efficiency and durability of the formwork system. Common materials include wood, steel, and plastic.

Wooden formwork is often used for smaller projects. It is lightweight and easy to work with. That said, it has a limited lifespan. According to a report by the International Journal of Construction and Building Materials, it can warp under moisture. This can lead to inaccuracies in concrete pours. Steel, on the other hand, offers great strength and longevity. It is reusable and can withstand harsh conditions. However, it is heavier and more expensive.

Plastic formwork is gaining popularity. It is easy to clean and resistant to corrosion. Some studies suggest it can reduce labor costs by up to 30%. Yet, the material can be less rigid than metal options. This may lead to formwork failures in complex designs. Each material comes with its own set of challenges. Proper selection is key to achieving successful construction outcomes.

Key Materials Used in Formwork and Their Properties

Advantages and Disadvantages of Different Formwork Systems

When it comes to formwork systems in construction, various options exist, each with unique advantages and disadvantages. Traditional timber formwork is commonly used due to its low initial cost. However, it can be time-consuming to set up. According to a construction industry report, labor costs can make up to 30% of the total project budget, leading to consideration of more efficient alternatives.

Steel formwork is durable and reusable. It allows for faster construction times, often reducing labor needs by more than 20%. However, the high initial investment can deter contractors. Moreover, the weight of steel can complicate transport and handling. This aspect may require additional equipment, which could negate some time savings.

Another option is plastic formwork. It is lightweight and resistant to moisture. However, its limited lifespan compared to steel can be a drawback. Studies show that while plastic formwork can cut costs initially, it may require more replacements over time. Understanding these nuances is vital for making informed decisions in construction projects.

Top Insights About Formwork in Construction Techniques

| Formwork Type | Advantages | Disadvantages | Use Cases |

|---|---|---|---|

| Timber Formwork | Cost-effective, Easy to use, Readily available | Not reusable for many cycles, Vulnerable to moisture | Residential buildings, Small projects |

| Steel Formwork | Highly durable, Reusable multiple times, Smooth finish | Higher initial cost, Heavier structure | High-rise buildings, Large scale constructions |

| Aluminium Formwork | Lightweight, Fast installation, Excellent surface finish | Costly compared to timber, Requires skilled labor | Multi-story buildings, Projects with tight timelines |

| Plastic Formwork | Lightweight, Resistant to corrosion, Easy to clean | Limited to specific constructions, Less sturdy | Small projects, Sustainable builds |

| Bubble Deck Formwork | Reduces material usage, Lightweight, Enhances thermal insulation | Complex installation process, Requires specialized knowledge | Floor systems, Sustainability-oriented projects |

Best Practices for Implementing Formwork in Projects

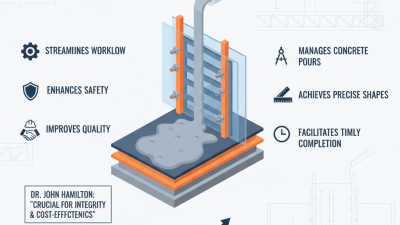

When implementing formwork in construction projects, attention to detail is crucial. Proper design of formwork systems ensures structural integrity. It is essential to understand the load requirements and withstand environmental conditions. Inadequate formwork can lead to costly errors and project delays.

Training the workforce is another key aspect. Skilled workers can identify and rectify potential issues early. Regular checks on the formwork during installation prevent problems later on. Sometimes, workers overlook small details; these can result in significant setbacks.

Additionally, it's important to review the formwork materials selected. Not all materials are suitable for every project. There are risks in using less durable options. Utilizing appropriate materials can enhance safety and efficiency. Challenges often arise when unexpected weather conditions occur. Planning for contingencies is vital for keeping projects on track.

Related Posts

-

Why Bulkhead Formwork is Essential for Successful Construction Projects

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

-

How to Choose the Best Cement Formwork for Your Construction Project?

-

How to Choose the Right Steel Formwork for Your Construction Project

-

Top Benefits of Circular Formwork for Construction in 2025

-

How to Choose the Right Circular Column Formwork for Your Construction Project