Top Guide to Understanding Formwork in Construction Industry?

Understanding formwork is essential in the construction industry. It serves as a temporary structure to hold concrete in place until it hardens. About formwork, its types and uses can greatly influence project success.

Different materials are used in formwork. Wood, steel, and plastic are common choices. Each material has unique properties that affect cost and durability. Builders must consider the project’s specific needs. It's not always easy to select the right formwork. Mistakes in this area can lead to delays or added expenses.

Some aspects of formwork require careful reflection. Workers must be trained to handle formwork safely. Misunderstanding instructions can lead to hazardous situations. Moreover, the design may need adjustments during construction. Flexibility and adaptability are crucial in this field. Understanding formwork helps ensure that projects run smoothly, but challenges remain.

Overview of Formwork and Its Role in Construction

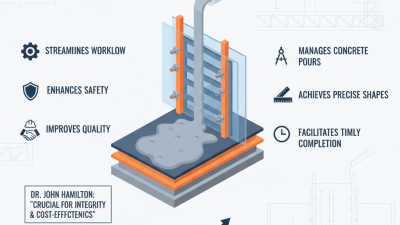

Formwork plays a crucial role in the construction industry. It refers to the temporary structures that mold concrete during the curing process. These frameworks ensure that concrete achieves the correct shape and strength. Without proper formwork, the entire construction process can be compromised. This can lead to structural weaknesses and safety hazards.

Understanding the different types of formwork is essential. There are traditional wooden forms, metal forms, and plastic forms. Each has its own advantages and disadvantages. Wooden formwork is easily customizable. However, it may not be as durable as metal or plastic options. On the other hand, metal forms are strong but can be expensive. Choose wisely based on your project needs.

Tips: Always inspect formwork before use. Check for any damages or wear. This can prevent issues during construction. Additionally, plan for the removal of formwork. Timing is key to maintaining the integrity of the concrete. Rushing this process can lead to unwanted cracking or deformation. Pay attention to details; small mistakes can lead to costly repairs later on.

Top Guide to Understanding Formwork in Construction Industry

| Formwork Type | Material | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Wooden Formwork | Wood | Residential Buildings, Foundations | Cost-effective, Easy to shape | Less durable, Requires skilled labor |

| Steel Formwork | Steel | High-rise Buildings, Bridges | Durable, Reusable | Higher initial cost, Heavy |

| Aluminum Formwork | Aluminum | Multi-story Buildings | Lightweight, Quick installation | Moderate cost, Requires precision |

| Plastic Formwork | Plastic | Small Projects, Residential | Lightweight, Water-resistant | Less sturdy, Limited reuse |

| Insulated Formwork | Polystyrene | Energy-efficient Buildings | Thermal performance, Quick setup | Costly, Limited load-bearing |

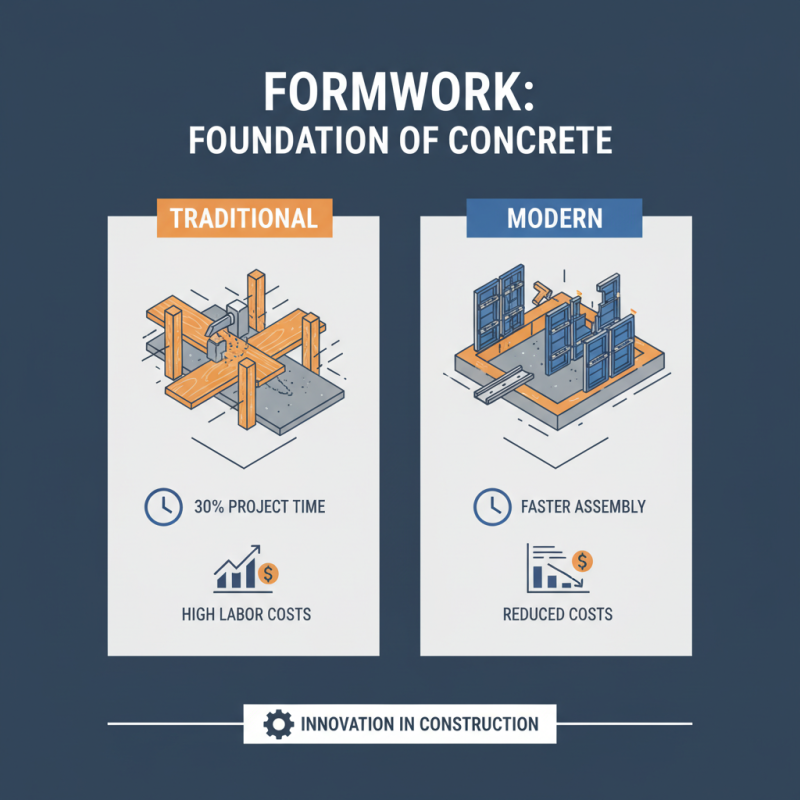

Types of Formwork: Traditional vs. Modern Approaches

Formwork plays a crucial role in the construction industry. It is essential for creating concrete structures. Traditionally, formwork was made from wood or steel. This approach often led to high labor costs. Reports indicate that traditional formwork systems can consume up to 30% of the construction time for a project.

Modern approaches have revolutionized the industry. Prefabricated formwork systems are gaining popularity. These systems reduce labor and material waste significantly. According to industry data, modern formwork can improve project timelines by 20% or more. However, it comes with its own challenges. The upfront costs of modern systems can be higher. This may deter some contractors from adopting these technologies.

Balancing the benefits and drawbacks of both types is vital. Traditional methods are reliable but slower. Modern techniques offer speed but require a skilled workforce. Finding the right mix can lead to more efficient construction. The choice often depends on project size and budget considerations. This complexity underscores the need for ongoing evaluation in formwork selection.

Design and Engineering Considerations for Formwork

In construction, formwork plays a crucial role. Good design can save money and time. According to the American Concrete Institute, poor design of formwork can increase costs by up to 25%. Engineers must consider load-bearing capacity. This is vital to ensure safety and compliance.

Material selection is also key. Options vary from plywood to steel. Each has its pros and cons. For instance, plywood is lightweight but may degrade quickly. Steel is more durable, yet heavier. The right choice depends on the project's specific needs. Data from industry reports suggest that 30% of delays are due to formwork issues.

Precision is paramount during installation. Misalignments can lead to significant flaws. Some teams overlook this, thinking it won’t matter. But even small errors can snowball into larger problems. The industry must learn from these mistakes. Regular training and updated practices are essential.

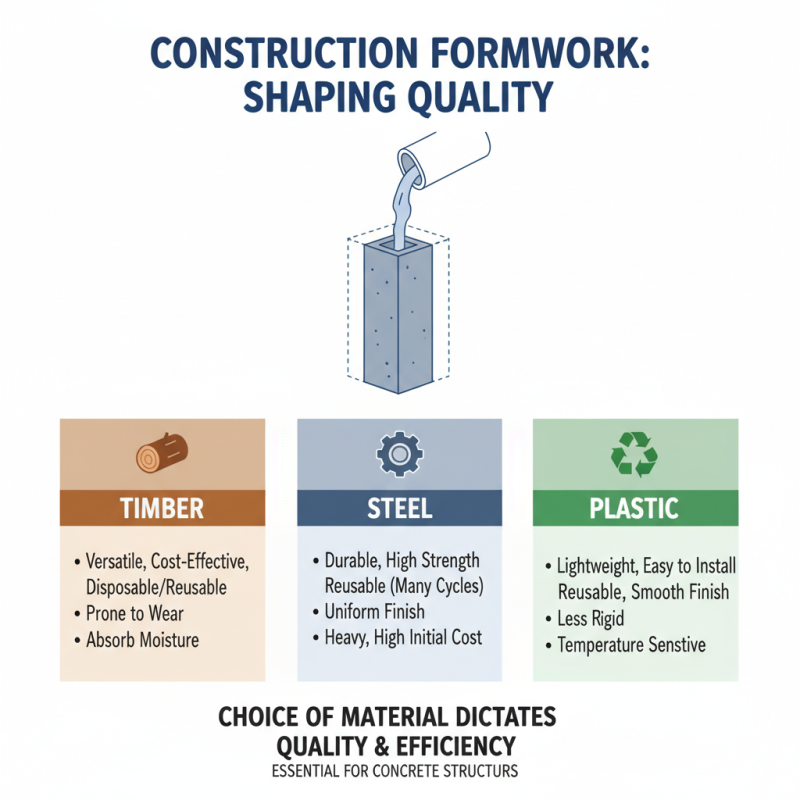

Materials Used in Formwork Construction

Formwork is essential in construction. It shapes concrete structures and dictates quality. The materials used greatly influence the outcome. Common materials include timber, steel, and plastic. Each has strengths and weaknesses.

Timber is frequently used for formwork. It is versatile and easy to work with. However, timber can warp under heat and moisture. A study noted that up to 30% of timber used in formwork can become damaged during a project. This increases costs unexpectedly. Plus, the need for continuous supply strains forests.

Steel is favored for its durability. It withstands pressure well and can be reused. However, steel's higher initial cost may deter some projects. A report highlighted that while 1,000 square feet of steel formwork can cost around $60,000, its longevity can make it cost-effective over time. Although plastic formwork is lightweight and resistant to moisture, it may lack strength in high-pressure applications. Balancing these materials requires careful consideration. Construction professionals must evaluate the project's specific needs.

Safety Practices and Regulations in Formwork Operations

In the construction industry, safety in formwork operations is crucial. Workers often face hazards from falling materials or unstable structures. Adhering to safety regulations helps mitigate these risks. For instance, proper alignment and securing of formwork components prevent collapses. Additionally, regular inspections are essential. Checks for wear and tear on materials can reveal potential dangers.

Training is vital for workers handling formwork. They should understand load limits and how to use safety gear. Without adequate training, mistakes can occur. Workers might underestimate the risks, leading to accidents. It is imperative to foster a culture of safety awareness. Communication on the job site should be clear. Everyone should be able to voice concerns regarding safety practices.

Documentation of safety protocols is often overlooked yet necessary. Detailed records of inspections and training sessions can aid compliance. Unfortunately, some teams neglect this aspect, risking futures. Understanding the balance between efficiency and safety is not always easy. Continuous training and awareness can enhance safety standards in formwork operations, ensuring a safer work environment for all.

Related Posts

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

Why Bulkhead Formwork is Essential for Successful Construction Projects

-

How to Choose the Right Steel Formwork for Your Construction Project

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

-

Top Benefits of Using Bendy Formwork in Modern Construction?