What is Formwork and What Are Its Advantages

Formwork plays a crucial role in construction. It serves as a temporary mold to shape concrete until it solidifies. According to John Smith, a renowned expert in construction technologies, "The advantages of formwork lie in its ability to enhance efficiency and save time." This highlights how formwork can streamline building processes.

Using formwork can significantly improve the quality of structures. It offers stability during the curing process. Workers can rely on formwork to achieve precise shapes and dimensions for walls, columns, and slabs. However, not all formwork systems are created equal. Choosing the wrong type can lead to complications. These challenges often arise from inadequate planning or poor material choices.

The advantages of formwork extend beyond efficiency. It contributes to safety on construction sites. Properly installed formwork reduces the risk of accidents. Yet, some teams do overlook essential safety checks. This oversight can negate the benefits expected from using formwork. Ultimately, understanding and utilizing formwork effectively can lead to better construction outcomes.

Definition of Formwork and Its Purpose in Construction

Formwork plays a crucial role in the construction process. It serves as a temporary structure that shapes and supports concrete until it achieves the necessary strength. This framework ensures that the concrete maintains its desired shape, thickness, and alignment. Proper formwork is essential for the integrity of any construction project.

There are several types of formwork, including wooden, metal, and plastic versions. Each type has its unique benefits and drawbacks. Wooden formwork is often readily available, but it may not provide the best finish. Metal formwork, while durable, can be heavy and expensive. Additionally, choosing the wrong type may lead to issues during pouring or setting.

The advantages of formwork extend beyond mere structural support. It can enhance the efficiency of construction schedules and reduce labor costs. Formwork can be reused multiple times, thereby providing savings in materials and time. However, if not designed correctly, it can lead to delays or additional expenses. Careful planning and execution are key to avoiding such pitfalls.

What is Formwork and What Are Its Advantages - Definition of Formwork and Its Purpose in Construction

| Dimension | Description |

|---|---|

| Definition | Formwork is a temporary or permanent mold used to pour concrete into a specified shape or dimension. |

| Types | Wooden, Metal, Plastic, or Fabric Formwork. |

| Purpose | To shape and support the concrete until it hardens. |

| Advantages | Increased construction speed, cost-effectiveness, improved safety, and versatile designs. |

| Disadvantages | Labor-intensive, potential for water leakage, and requires skilled labor for setup and removal. |

| Time Frame | Formwork typically needs to be in place for at least 24-48 hours after concrete pouring depending on conditions. |

| Materials Cost | Costs vary by type: Wooden forms are generally cheaper, while metal forms are more durable but costlier. |

Types of Formwork: Traditional vs. Modern Solutions

Formwork is essential in construction. It shapes concrete until it hardens. There are two main types of formwork: traditional and modern solutions. Traditional formwork usually involves wood or plywood. It is often cost-effective but time-consuming to set up. Workers must nail and cut pieces manually. Reports indicate that labor can consume up to 30% of the total project time. This limits efficiency and can lead to errors if not handled carefully.

Modern formwork, on the other hand, includes materials like steel and plastic. It offers quick assembly and disassembly. Many contractors favor modern solutions for large projects. They can reduce labor time by nearly 50%. However, initial costs are higher, which can deter small builders from using them. The industry still grapples with this trade-off. Environmental concerns also arise from using certain materials that are not as sustainable.

Both types have advantages and shortcomings. The choice often depends on project size and budget. Traditional methods have a nostalgic appeal but modern solutions drive speed. Balancing cost with efficiency remains a challenge. Sustainable choices in materials can further complicate decisions.

Comparison of Formwork Types: Traditional vs. Modern

Key Advantages of Using Formwork in Construction Projects

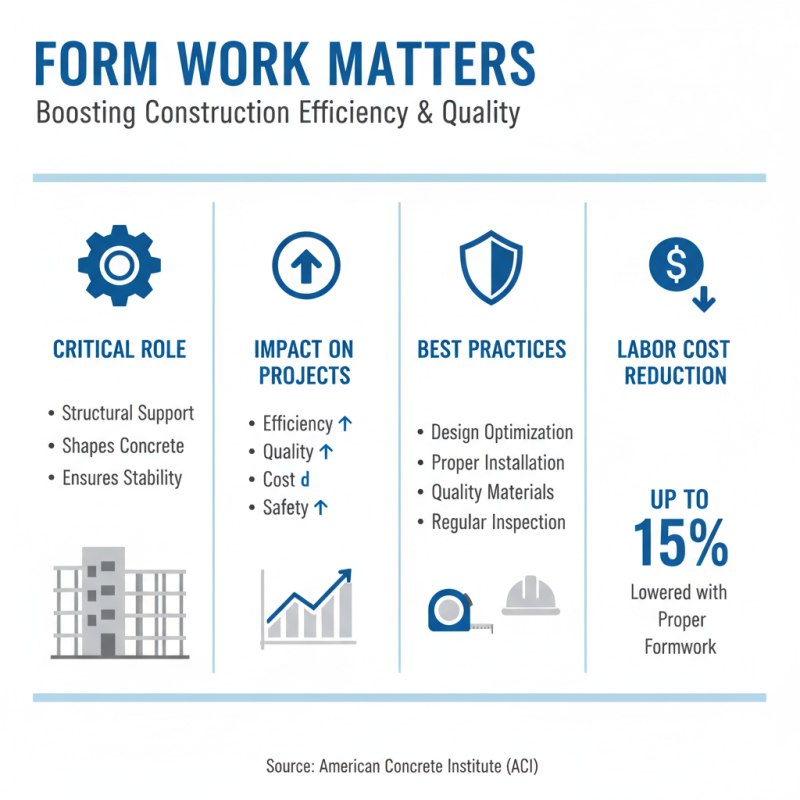

Formwork plays a crucial role in construction. It provides temporary structures that shape and support concrete until it sets. One key advantage of using formwork is the enhanced efficiency it brings to projects.

According to a report by the National Concrete Association, using modern formwork systems can reduce construction time by up to 30%. This allows projects to progress faster and meet tight deadlines.

Another significant benefit is the improved quality of the final product. Well-designed formwork ensures that concrete is poured evenly. This can lead to fewer defects and a longer lifespan for structures.

A study published in the Journal of Construction Engineering found that using formwork reduces wastage. It highlights how proper formwork management can minimize material costs by about 15%.

However, formwork also requires careful planning. Mistakes in sizing or placement can lead to project delays and increased expenses.

In addition to efficiency and quality, safety is an important aspect. Properly installed formwork can prevent accidents on-site. However, inadequate training for workers can negate these safety advantages.

Industry reports indicate that lack of training leads to a 20% increase in workplace accidents.

Construction managers must prioritize training to maximize benefits while ensuring worker safety. Overall, the advantages of using formwork are clear, but attention to detail is essential for success.

Materials Commonly Used for Formwork Construction

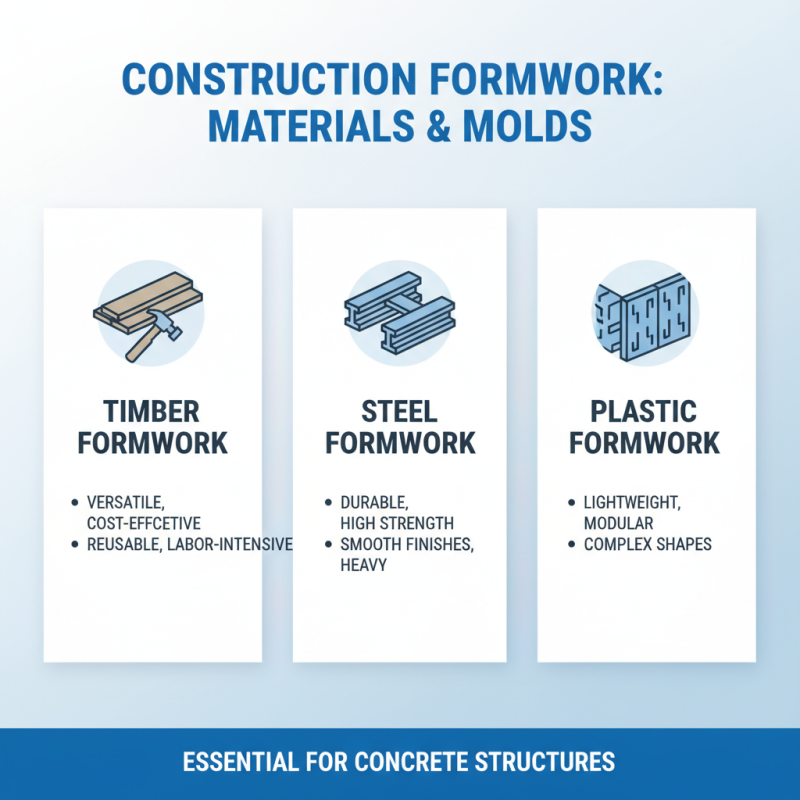

Formwork is an essential component in construction, providing the mold needed for concrete structures. The materials used for formwork vary based on project requirements and environmental conditions. Commonly used materials include timber, steel, and plastic. Each has its own advantages and disadvantages.

Timber is versatile and easy to work with. It can be shaped on-site, which is helpful for unique projects. However, it may not be as durable as other materials. A report from the Global Construction Market indicates that timber formwork can lead to waste if not reused efficiently, with some estimates suggesting up to 20% waste in certain projects.

Steel formwork is strong and reusable. It can withstand harsh conditions, making it a long-term investment. Reports show that it can reduce labor costs by 30% in repetitive jobs. However, transporting steel can be challenging due to its weight. This limits its use in remote areas. Plastic formwork is lightweight and flexible, allowing for rapid assembly. In some cases, it may lack the strength needed for large-scale projects.

Choosing the right material requires careful consideration of project specifics. Builders often face dilemmas regarding cost versus durability. Balancing these factors is crucial for optimal outcomes.

Best Practices for Formwork Design and Implementation

Formwork is critical in construction. Its design and implementation can significantly affect the project's outcome. When developing formwork, applying best practices can lead to higher efficiency and quality. According to the American Concrete Institute, proper formwork can reduce labor costs by up to 15%. That's substantial for project budgets.

One key practice is considering the materials used in formwork construction. The choice between timber, steel, and aluminum greatly impacts durability and ease of use. Timber may be cost-effective but can warp or rot. On the other hand, steel offers durability but may be more challenging for workers to handle. It’s essential to involve skilled labor in the design phase. This ensures the formwork meets specific project needs, from load-bearing capabilities to weather resistance.

Another important aspect is the design of the formwork itself. Engineering it to facilitate easy assembly is vital. Complicated structures can lead to mistakes and delays. Research by the National Institute of Standards and Technology suggests that over 30% of construction delays stem from formwork issues. Investing time into effective design may seem tedious. However, the precision it brings can prevent costly mistakes down the line. Keeping a constant feedback loop with the construction team can further improve practices, fostering an environment of shared learning.

Related Posts

-

How to Choose Bendy Formwork for Your Construction Project?

-

Why Is Bracing in Formwork Essential for Construction Success?

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

-

2026 Top Trends in Ceiling Formwork Design and Technology?