What is Flexible Formwork and How Can It Benefit Your Construction Projects

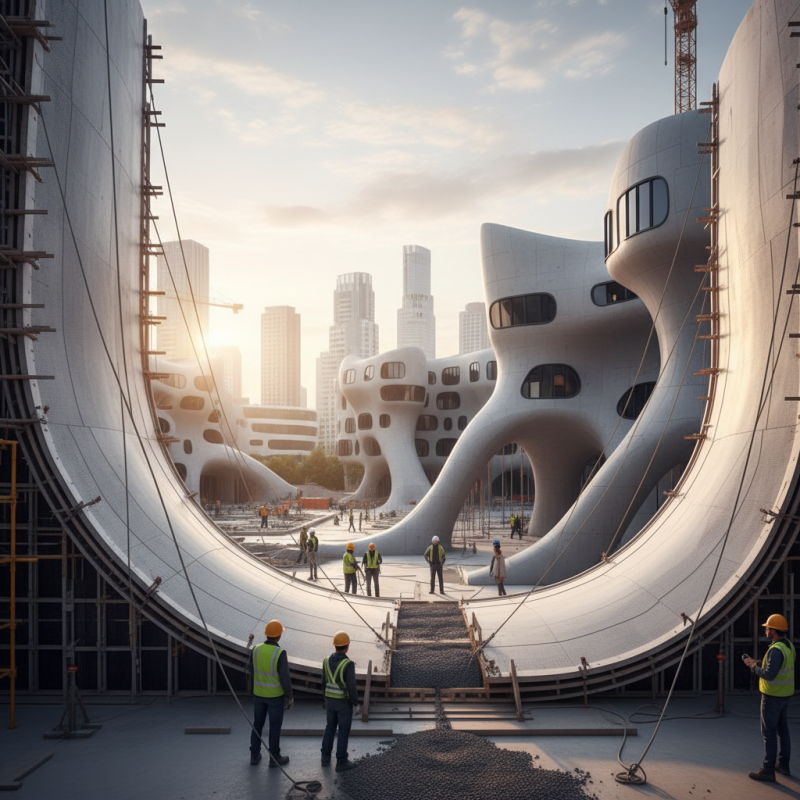

In the ever-evolving landscape of construction, innovative techniques and materials play a crucial role in enhancing efficiency and reducing costs. One such advancement that has gained significant attention is flexible formwork. Unlike traditional rigid formwork systems, flexible formwork offers architects and builders the ability to create unique shapes and contours while maintaining structural integrity. This innovative approach not only streamlines the construction process but also opens up new avenues for creative design, allowing for more aesthetically pleasing concrete structures that can fit within diverse architectural visions.

Flexible formwork is particularly advantageous in projects that require customized solutions due to site constraints or specific design requirements. Its adaptability can lead to reduced material waste and quicker installation times, translating to significant cost savings and improved project timelines. By embracing flexible formwork, construction professionals can enhance the sustainability of their projects while delivering high-quality, durable results that meet modern building standards. Overall, the integration of flexible formwork into construction practices represents a significant shift towards more versatile and environmentally-conscious building methods.

What is Flexible Formwork and Its Role in Modern Construction Methods

Flexible formwork is an innovative construction technique that leverages adaptable materials to shape concrete structures in a cost-effective and efficient manner. Unlike traditional rigid formwork, flexible formwork can be easily manipulated to create complex and varied geometries. This method allows for greater design freedom, enabling architects and engineers to explore unique forms that were previously challenging or prohibitively expensive to produce. As modern construction increasingly prioritizes sustainability and efficiency, flexible formwork provides an ideal solution by reducing material waste and lowering labor costs.

The role of flexible formwork in modern construction methods is significant, impacting both the performance of structures and the overall construction process. By utilizing materials such as fabric or thin membrane systems, designers can achieve intricate designs while maintaining structural integrity. This versatility not only enhances aesthetic appeal but also improves thermal efficiency and reduces resource consumption during the construction phase. Additionally, flexible formwork can be customized to meet specific project requirements, making it an essential tool in achieving innovative designs while adhering to sustainable practices. The growing adoption of this technique reflects a shift towards more dynamic and environmentally conscious construction methodologies.

Advantages of Flexible Formwork: Cost Efficiency and Time Savings

Flexible formwork has emerged as a game changer in the construction industry, offering significant cost efficiency and time savings. Traditional formwork systems can be expensive and labor-intensive, often requiring extensive materials and a considerable amount of time for installation and removal. In contrast, flexible formwork adapts to various shapes and sizes, allowing for quicker setup and reduced material costs. This adaptability not only streamlines the construction process but also minimizes waste, ultimately leading to further savings on projects.

One of the key advantages of flexible formwork is its ability to facilitate the creation of complex geometries without necessitating elaborate support structures. This means that contractors can execute innovative designs while keeping labor costs down. Additionally, since flexible formwork is lighter and easier to handle, it often requires fewer workers to manage, leading to quicker project turnaround times. As a result, construction teams can allocate their resources more effectively, enhancing overall productivity.

Tips for maximizing the benefits of flexible formwork include ensuring proper training for your team on its use and installation, which can reduce errors and inefficiencies. Additionally, consider incorporating flexible formwork early in the design phase to identify potential challenges and adjust your project plans accordingly. Consistent communication among team members throughout the construction process can also help in optimizing workflows, further enhancing both cost savings and time efficiency.

Key Materials Used in Flexible Formwork and Their Performance Metrics

Flexible formwork is an innovative approach in the construction industry that allows for the creation of unique shapes and designs. The success of flexible formwork largely depends on the materials used, which directly influence performance metrics such as strength, durability, and ease of use. Common materials include high-strength fabrics, polymers, and composite materials, each offering distinct advantages.

High-strength fabrics, for instance, provide excellent flexibility and can easily conform to diverse shapes, making them ideal for intricate designs. These fabrics are often combined with lightweight support structures that enhance stability without adding excessive weight. On the other hand, polymers are favored for their water resistance and longevity, making them suitable for various environmental conditions. Composite materials, which blend different materials to optimize performance, become increasingly popular due to their ability to reduce costs while maintaining strength and adaptability.

Performance metrics such as thermal insulation, load-bearing capacity, and resistance to environmental factors are crucial in evaluating the effectiveness of flexible formwork materials. Projects utilizing these materials have reported improved efficiency in construction timelines and enhanced aesthetic results. As the industry continues to evolve, the materials for flexible formwork will play a pivotal role in shaping the future of architectural design and construction methodologies.

What is Flexible Formwork and How Can It Benefit Your Construction Projects

| Material Type | Material Properties | Performance Metrics | Benefits |

|---|---|---|---|

| Geotextiles | High tensile strength, water permeability | Durability up to 10 years, 100% recycled materials | Cost-effective, environmentally friendly |

| Plywood | Lightweight, high compressive strength | Load-bearing capacity of 50 PSI | Versatile, widely available |

| Fabric Formwork | Flexible, lightweight, reusable | Reduced material costs by 30% | Enhances concrete shape versatility |

| PVC Sheets | Waterproof, UV resistant | Lifespan of 15 years | Reduces formwork weight, easy to handle |

| Aluminum Formwork | Strong, reusable, lightweight | 30+ uses, 100% recyclable | Accelerates project schedule, reduces labor costs |

Case Studies: Successful Implementation of Flexible Formwork in Projects

Flexible formwork has gained traction in recent years, especially in projects that require unique and adaptable designs. One exemplary case study is the use of flexible formwork in the construction of a curved bridge. The project team opted for this innovative approach to accommodate the bridge's non-linear geometry. By utilizing flexible formwork, they were able to create smooth, organic shapes that traditional rigid formwork could not achieve. This method not only reduced material waste but also minimized labor costs, illustrating the economic advantages of flexible formwork in complex constructions.

Another notable implementation can be seen in the development of residential complexes. In one project, architects employed flexible formwork to create visually appealing, undulating wall surfaces that enhanced the overall aesthetic of the buildings. The adaptable system facilitated quick adjustments on-site, allowing for last-minute design changes without significant delays. This case highlights the versatility of flexible formwork, as it enables builders to respond to evolving project demands while maintaining high-quality finishes. The successful execution of these projects underscores the potential of flexible formwork to revolutionize construction methodologies, providing both functional and creative benefits.

Benefits of Flexible Formwork in Construction Projects

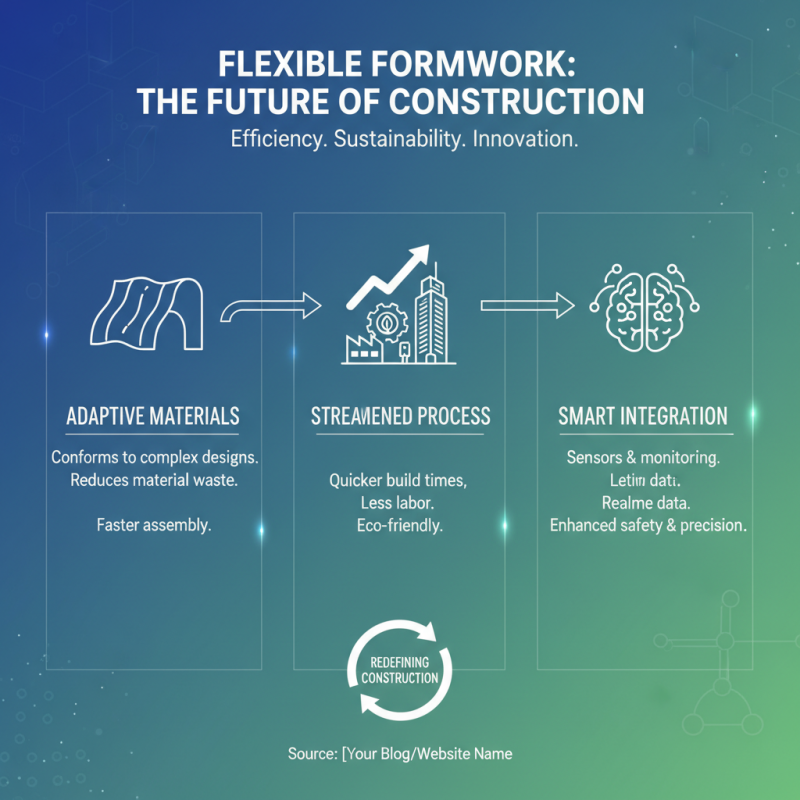

Future Trends: Innovations in Flexible Formwork Technology and Design

The evolution of flexible formwork technology is poised to redefine construction methods, paving the way for increased efficiency and sustainability. One of the most prominent innovations is the use of advanced materials that adapt to various structural requirements, allowing for more intricate designs without the need for traditional rigid blocks. This flexibility not only reduces material waste but also streamlines the construction process, enabling faster assembly and disassembly. Moreover, the integration of smart technologies—such as sensors and real-time data monitoring—enhances safety and precision, providing builders with valuable insights during the project lifecycle.

Additionally, the trend towards sustainable construction has fostered the development of eco-friendly flexible formwork options. By utilizing biodegradable or recyclable materials, these innovations align with the growing demand for greener building practices. The design possibilities are expanding, allowing architects and engineers to create more organic shapes and contours that were previously challenging to achieve with conventional formwork systems. This shift not only improves the aesthetic appeal of structures but also enhances their performance through better energy efficiency and durability. As the construction industry evolves, flexible formwork technologies will play a critical role in shaping the future of architectural design and building processes.