How to Use Flexible Concrete Formwork for Innovative Construction Solutions?

In the realm of modern construction, "flexible concrete formwork" is emerging as a transformative solution. This innovative approach allows for complex shapes and designs, which traditional methods struggle to achieve. A recent industry report highlighted that innovations like flexible formwork can reduce material consumption by up to 30% and construction time by 20%. Such improvements reflect a growing trend towards sustainability and efficiency in construction practices.

Implementing flexible concrete formwork poses challenges. While it can create intricate architectural designs, the learning curve for teams may slow initial adoption rates. Moreover, not all markets are equipped to handle the required technology. However, the potential for customization and adaptability makes it an appealing option for architects and builders. Errors in early projects could lead to increased costs, but this underscores the need for thorough training and planning.

The future of flexible concrete formwork holds promise. As more companies invest in this technology, study results are likely to yield further insights. Continuous improvements in material science may enhance the performance of flexible formwork. On the flip side, the industry must address the skills gap and ensure professionals are well-prepared for these innovations.

Understanding Flexible Concrete Formwork and Its Advantages

Flexible concrete formwork has gained traction in recent years for its numerous advantages in construction. This innovative approach allows for versatile shapes and designs, enhancing architectural creativity. According to a report by the Global Construction Review, using flexible formwork can reduce material waste by up to 30%. This not only lowers costs but also contributes to sustainable building practices.

Design flexibility is a standout benefit. Designers can create unique structures that traditional methods may not permit. With flexible forms, curves and complex shapes become possible. A study by the American Concrete Institute highlights that projects utilizing this method saw a 20% decrease in labor costs. This efficiency is appealing to many construction professionals.

Tips: Ensure proper planning when using flexible formwork. Always consider the structural integrity of the design. Testing prototypes can help identify any weaknesses. Additionally, don’t overlook the potential challenges in installation. Tools may be needed to secure and maintain the formwork during the pour. Reflect on these aspects to guarantee successful application.

How to Use Flexible Concrete Formwork for Innovative Construction Solutions?

| Dimension | Description | Advantages | Applications |

|---|---|---|---|

| Material Flexibility | Ability to conform to various shapes | Reduces waste and allows for creative designs | Curved walls, sculptural forms |

| Ease of Installation | Lightweight and easy to handle | Speeds up construction time | Residential buildings, commercial spaces |

| Cost Efficiency | Lower material costs compared to traditional formwork | Reduces overall project budget | Affordable housing projects |

| Durability | Resistant to weather conditions | Long-lasting and reusable | Infrastructure, civil engineering works |

| Versatility | Can be used for various concrete applications | Adaptable to different construction methods | Precast elements, in-situ casting |

Key Materials Used in Flexible Concrete Formwork

Flexible concrete formwork is transforming construction practices. This innovative approach utilizes materials that adapt to various shapes and designs. Key materials in flexible formwork include textiles, plastics, and rubber. Each of these materials offers unique benefits and challenges.

Textiles, for example, provide lightweight solutions. They can be manipulated easily to create complex forms. However, selecting the right type of textile is crucial. Some fabrics may not withstand the pressures of wet concrete. Plastics are another option. They are durable and can be molded into intricate shapes. Nevertheless, the environmental impact of plastics is worth considering.

Rubber formwork is gaining attention as well. It offers excellent flexibility and resilience. However, rubber can be expensive. Each choice carries potential drawbacks. Finding the best balance in material selection is essential for successful projects. Testing different combinations might yield innovative results. The journey of trial and error is valuable in this evolving field.

Usage of Key Materials in Flexible Concrete Formwork

Techniques for Designing and Building with Flexible Formwork

Flexible concrete formwork is transforming construction. By allowing for unique shapes, it encourages creativity. Builders can design flowing curves or unusual angles. This is more than aesthetics; it opens up functionality.

Designing with flexible formwork requires careful planning. Understanding how concrete flows is crucial. The formwork must support the concrete until it cures. This is a balancing act. Some designs may not hold up under pressure, leading to failures. Iterative testing can help to avoid such pitfalls.

Construction crews should embrace innovation cautiously. Training is necessary to ensure everyone understands the material. Mismanagement can lead to wasted resources or structural issues. Sustainable practices should be prioritized. Choosing eco-friendly materials is essential for the future of construction. Adjustments and reflections on past projects can lead to better outcomes.

Application Examples of Flexible Concrete Formwork in Construction

Flexible concrete formwork is revolutionizing construction methods. Its adaptability enables architects to explore unique designs. For instance, in an urban project, contractors used flexible formwork to create curvilinear structures. According to a recent industry report, projects employing flexible formwork can reduce concrete waste by up to 30%. This waste reduction is crucial for sustainable building practices.

One notable example includes the use of flexible formwork in residential buildings. These homes exhibit organic shapes while maintaining structural integrity. The flexibility allows for rapid prototyping, enabling teams to test designs before final approval. Data from several case studies show that projects completed with flexible formwork had improved timelines by approximately 25%.

Tips: When using flexible formwork, consider the weight of the concrete mix. Lighter mixes can enhance formwork performance. Ensure to budget for potential design revisions. Being adaptable during the project can lead to more innovative outcomes. Remember, flexibility comes with challenges. On-site adjustments might be necessary to achieve the perfect curve. Embrace the learning process, as it fosters creativity.

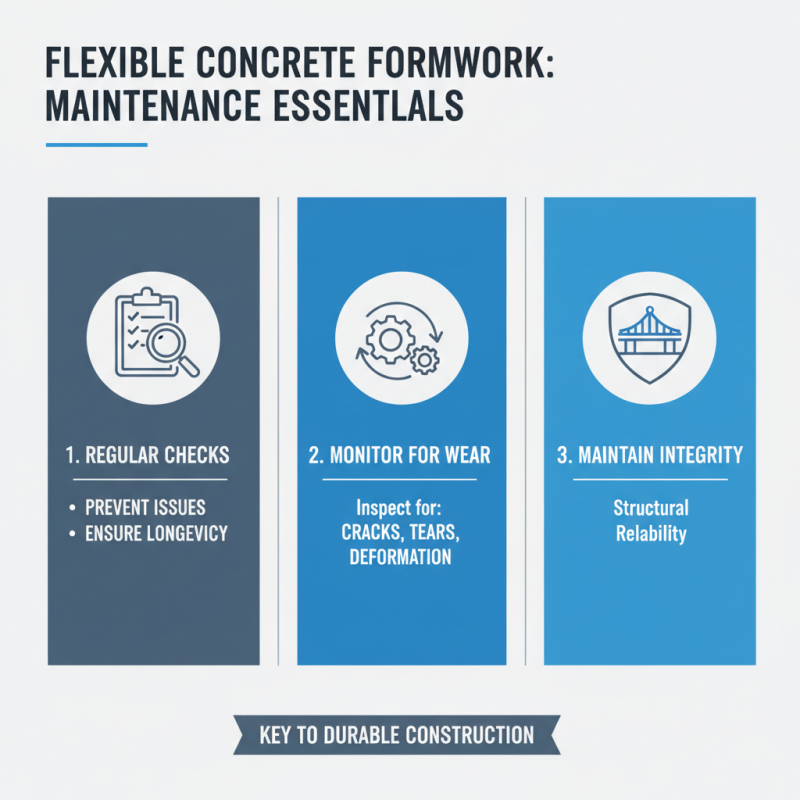

Best Practices for Maintaining and Managing Flexible Formwork Systems

When utilizing flexible concrete formwork systems, proper maintenance is key. Regular checks can prevent significant issues. Monitor the formwork for wear and tear. Look for signs of damage or deformation. This ensures the structure maintains its integrity.

Tips: Always clean the formwork after use. Dirt can affect future concrete finishes.

Managing these systems requires attention. Store formwork in a dry area. Moisture can lead to mold or deterioration. Inspect them before each use. Keeping a maintenance log can help track their condition.

Tips: Use gentle cleaning agents for upkeep. Harsh chemicals can harm the material.

Flexibility in design helps, but problems can arise. Templates can shift if not secured properly. This can lead to uneven surfaces. Be vigilant during installations. Adjustments might be needed. Careful planning can mitigate some challenges.

Tips: Take precise measurements before pouring concrete. Small errors can lead to big issues later.

Related Posts

-

Top Benefits of Circular Formwork for Construction in 2025

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

2025 Top Round Column Formwork Techniques and Best Practices Guide

-

How to Choose Bendy Formwork for Your Construction Project?

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices