Ultimate Tips for Using Bulkhead Formwork Effectively?

In construction, effective use of bulkhead formwork can greatly enhance project efficiency. This formwork system plays a critical role in creating sturdy walls and foundations. Properly implemented, it helps in achieving precise dimensions and reducing material wastage.

Using bulkhead formwork demands a thorough understanding of its components. Each piece must be carefully selected and positioned to ensure stability. However, mistakes can happen, such as misalignment or using inadequate materials. Attention to detail is crucial, as these errors can lead to costly delays.

Moreover, the assembly process is often overlooked. Clear communication among team members is essential. If workers are not informed about their roles, confusion may arise. Ultimately, reflecting on past experiences can guide better practices in future projects.

Understanding Bulkhead Formwork and Its Applications

Bulkhead formwork is essential in construction. It helps create vertical walls in concrete structures. This method is commonly used in basements, high-rise buildings, and tunnels. According to industry reports, the global formwork market is expected to reach $9.5 billion by 2025. This highlights the growing reliance on effective formwork systems.

Understanding the applications of bulkhead formwork is crucial. It allows for precise alignment and support during the curing process. However, incorrect installation can lead to structural issues. A study found that over 15% of construction delays are attributed to formwork failures. Such statistics underline the need for thorough training and quality checks.

Moreover, bulkhead formwork requires proper coordination among team members. Miscommunication about dimensions or schedules often causes setbacks. It’s vital to distinguish between necessary adjustments and those that could introduce complications. A balance between efficiency and caution is essential. Keeping these considerations in mind can improve project outcomes significantly.

Effective Applications of Bulkhead Formwork

Key Advantages of Using Bulkhead Formwork in Construction

Bulkhead formwork is transforming modern construction. This system offers key advantages that can optimize project timelines and costs. One significant benefit is improved efficiency. A study by the Construction Industry Institute found that effective formwork can reduce labor costs by 20% to 30%. This reduction stems from faster installation and minimal rework, which enhances productivity on-site.

Moreover, bulkhead formwork provides structural integrity during concrete pouring. This formwork supports the weight and pressure of fresh concrete, minimizing the risk of failure. According to a report by the American Concrete Institute, using the correct formwork can minimize concrete wastage by up to 15%. When implemented correctly, it leads to a cleaner work environment and less environmental impact.

Despite the advantages, some challenges exist. Poor installation can lead to leaks or failures. Workers need adequate training to use bulkhead systems effectively. Also, the initial cost of formwork materials may deter some projects. However, the long-term benefits often outweigh these initial hurdles. Each project demands careful planning and reflection to ensure the best outcomes.

Step-by-Step Guide to Proper Installation of Bulkhead Formwork

Installing bulkhead formwork requires careful planning and execution. Start by ensuring that your site is prepared and free from debris. Check that the ground is level. An uneven surface can lead to issues.

Before you begin, gather all necessary materials and tools. This includes panels, stakes, and supports. It’s critical to have everything on hand to avoid interruptions. Measure your space accurately. Mistakes at this stage can be costly.

Once you’re ready, erect the bulkhead formwork. Secure the panels tightly to prevent any movement during concrete pouring. Use stakes for added support, ensuring they are driven deep enough into the ground. Inspect your setup frequently. If you notice any gaps or misalignments, correct them immediately.

Tip: Always secure your formwork firmly to resist the pressure from wet concrete. This simple step can save you time and trouble. Consider using braces for extra stability.

As the pour approaches, double-check your setup. Preparing for the unexpected is key. If the formwork shifts, you could face significant setbacks. Reflect on your process. What went well? What can improve next time? Each project is a learning experience.

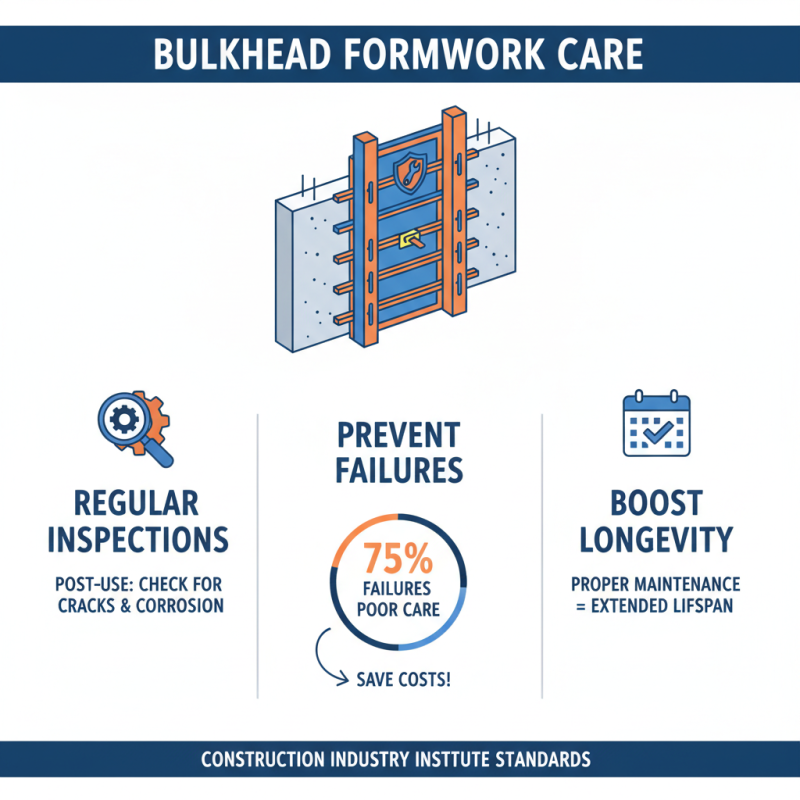

Best Practices for Maintenance and Care of Bulkhead Formwork

Proper maintenance of bulkhead formwork is crucial for its longevity and effectiveness. According to industry standards, regularly inspecting for wear and damage should be a priority. In a recent report by the Construction Industry Institute, 75% of formwork failures result from inadequate care. Simple checks can prevent costly repairs. For instance, look for cracks or corrosion after each use.

Cleaning bulkhead formwork effectively is essential. Residual concrete can cause issues with subsequent pours. Using high-pressure water can efficiently remove debris. Ensure all components are dried before storage to prevent mold growth. Neglecting this step can lead to a decrease in performance by 25%, as noted in an analysis by the Concrete Reinforcing Steel Institute.

Storage conditions also matter. Keeping formwork in a dry, temperature-controlled environment is ideal. However, many workers overlook this aspect. Improper storage can reduce the lifespan of the material. Reflecting on how often equipment is left outdoors, maintenance isn’t just about care; it’s also about proactive measures. A more engaged approach could significantly enhance performance and durability.

Common Challenges in Bulkhead Formwork and How to Overcome Them

When using bulkhead formwork, several common challenges often arise. One major issue is ensuring proper alignment. Misalignment can lead to uneven walls, which complicates the entire building process. A simple solution is to use string lines and levels frequently during installation. Regular checks can prevent costly adjustments later.

Another challenge is managing grout leakage. It's frustrating to find that grout has seeped out, creating a mess. To mitigate this, workers should ensure that all joints are sealed tightly before pouring. Utilizing quality sealants can make a significant difference. Observing these details can save both time and resources.

Lastly, ensuring worker safety with bulkhead formwork is essential. Heavy panels can cause injuries if not handled properly. Training on safe lifting techniques is critical. Workers must be vigilant and communicate effectively. Poor handling can lead to accidents. Emphasizing safety ensures a smoother workflow.

Ultimate Tips for Using Bulkhead Formwork Effectively

| Tip | Description | Common Challenges | Solutions |

|---|---|---|---|

| Proper Material Selection | Choose the right materials to ensure structural integrity and durability. | Using subpar or incorrect materials can lead to failures. | Conduct comprehensive material testing before project initiation. |

| Accurate Measurements | Ensure precise measurements and layouts before installation. | Inaccurate measurements can result in misalignment and structural issues. | Use laser tools and double-check all measurements. |

| Installation Techniques | Employ proper installation techniques for safety and efficiency. | Improper installation can lead to accidents and rework. | Provide training sessions for workers on installation best practices. |

| Regular Inspections | Conduct regular inspections during the construction process. | Neglecting inspections can lead to unnoticed defects. | Set a schedule for periodic inspections and adjustments. |

| Effective Communication | Maintain clear communication amongst the team on-site. | Poor communication can result in misunderstandings and mistakes. | Use communication tools and hold daily briefings. |

Related Posts

-

How to Use Beam Slab Formwork for Effective Construction?

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

Top Benefits of Circular Formwork for Construction in 2025

-

2025 Top Round Column Formwork Techniques and Best Practices Guide

-

2026 Top Trends in Ceiling Formwork Design and Technology?