How to Choose the Right Timber for Concrete Formwork?

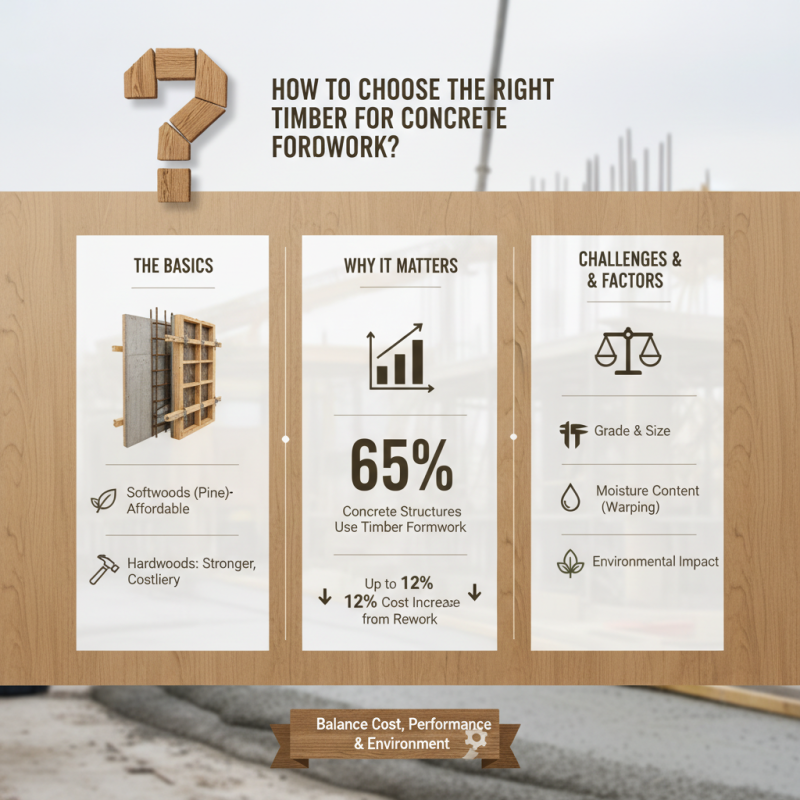

Choosing the right timber for concrete formwork is crucial for successful construction projects. According to a report by the National Wood Council, nearly 65% of all concrete structures use timber formwork. This statistic emphasizes timber's significance in achieving structural integrity and durability. The suitability of timber directly affects project efficiency and costs.

Selecting the proper timber ensures optimal performance. For instance, softwoods, like pine, are often more affordable. However, hardwoods provide greater strength but may increase overall expenses. An analysis published by the American Concrete Institute noted that improper timber selection can lead to project delays and increased costs. In some cases, inadequate formwork resulted in up to 12% of total project costs being inflated due to rework.

Despite the abundance of options, challenges persist. Various timber grades, sizes, and environmental impacts complicate decision-making. Many underestimate the importance of moisture content, which can lead to warping or bending. Therefore, finding the right balance is not always straightforward. Decision-makers must weigh initial costs against long-term performance and environmental factors. Ultimately, the choice of timber for concrete formwork demands critical reflection.

Types of Timber Used for Concrete Formwork and Their Properties

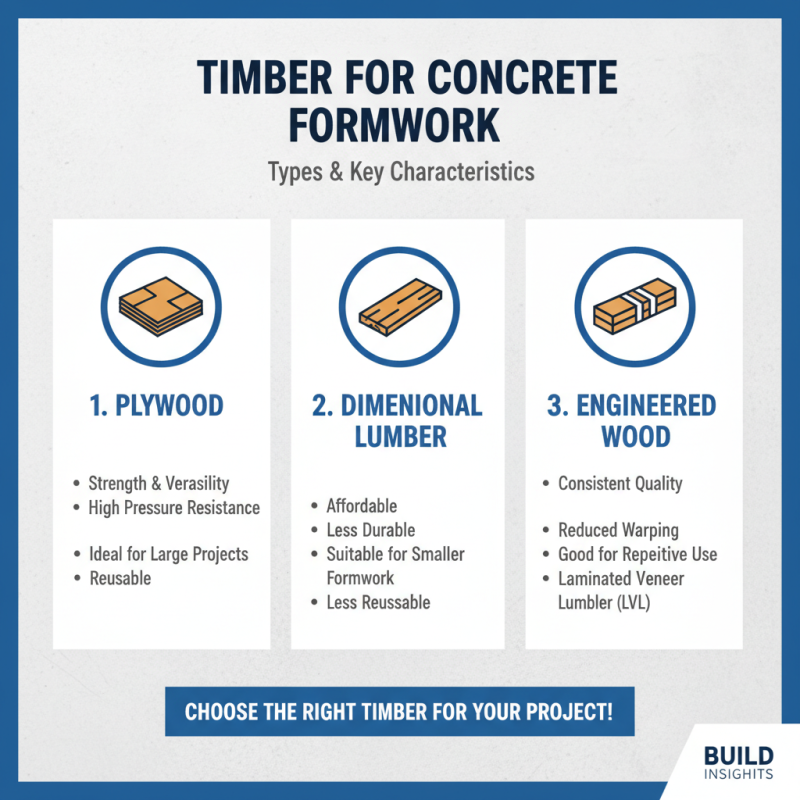

When selecting timber for concrete formwork, understanding the types available is essential. Common choices include plywood, dimensional lumber, and engineered wood. Plywood is popular due to its strength and versatility. It can withstand high pressures from concrete, making it ideal for large projects. On the other hand, dimensional lumber is often used for smaller formwork. It’s more affordable but less durable.

Engineered wood, such as laminated veneer lumber, offers excellent load-bearing capacity and resistance to warping. Reports from structural timber associations highlight that laminated lumber can handle over 50% more load than regular timber. While it costs more, the longevity might justify the price.

**Tip:** Always consider humidity and climate. They impact timber durability. In humid areas, select treated timber to prevent rot.

Formwork systems create mold shapes for concrete. Ensuring the right timber choice can significantly affect the outcome. However, not all timber behaves consistently. Some types may expand or contract with temperature changes. Regular inspection of formwork before pouring concrete is crucial.

**Tip:** Use a moisture meter. This tool helps detect moisture levels in timber, ensuring it is suitable for your project.

Moisture Content and Its Impact on Timber Durability in Formwork

Moisture content plays a crucial role in the durability of timber used for concrete formwork. According to industry reports, timber with a moisture content exceeding 20% can lead to significant structural issues. High moisture levels increase the risk of warping and decay. This can compromise the integrity of formwork, potentially leading to construction delays and increased costs.

Timber that remains dry is often more robust. A moisture content below 15% is generally recommended for optimal performance. Dry timber can withstand the weight and pressure of wet concrete better. It's essential to monitor moisture levels during storage and application. Utilizing moisture meters can provide accurate readings, ensuring that the timber maintains its integrity throughout the construction process.

However, achieving the ideal moisture content isn't always easy. Environmental factors such as humidity and rain can affect timber even after treatment. Contractors should be aware that even minor fluctuations in moisture can reduce the lifespan of the formwork. This is an area that requires constant attention and careful planning to avoid detrimental outcomes.

Strength Grades of Timber: Selecting the Right Class for Structural Support

When choosing timber for concrete formwork, understanding strength grades is essential. The strength class determines how well the timber will support loads during construction. Different grades have varying capacities, and selecting an appropriate one can make a significant difference.

For instance, if you opt for a lower strength grade, you may face issues like warping or bending. This could lead to structural instability of the formwork. On the other hand, higher grades may come at a greater cost. It’s crucial to balance quality and budgetary constraints. Sometimes, a mid-range option might seem like a safe bet, but it may not always meet the necessary standards in all scenarios.

Not every project is identical. A small-scale task might not need the strongest timber, while larger projects often require robust support. Evaluating your project's needs can prevent overspending. Always remember, the right grade of timber can enhance safety and overall outcomes. However, ignoring this detail can lead to costly mistakes in the long run.

Environmental Considerations in Timber Sourcing for Construction Projects

When sourcing timber for concrete formwork, environmental considerations are essential. Choosing sustainably-sourced wood can help reduce deforestation. Not all timber is created equal; some types deplete natural resources faster. It's crucial to understand the sourcing methods used. Look for timber that comes from managed forests. Certified sources often follow ecological guidelines that protect biodiversity.

Localized supply chains can also minimize environmental impact. Transporting timber over long distances increases carbon footprints. Supporting local suppliers not only contributes to the economy but also encourages better forestry practices. However, finding the right local supplier can be tricky. Some may not adhere strictly to sustainable practices.

There’s no perfect solution in timber sourcing. Sometimes, the cheapest option lacks transparency. Rushing decisions may lead to choosing timber that harms the environment. Assessing the full lifecycle of timber—from growth to disposal—can be daunting yet necessary. Reflecting on these aspects can lead to more responsible choices in construction projects. Ultimately, the goal is to balance cost, quality, and sustainability.

Cost Analysis: Comparing Timber Options for Concrete Formwork Efficiency

Choosing the right timber for concrete formwork can be challenging. Cost analysis is crucial when comparing timber options. Different types of timber have various costs and durability levels. Cheap options may seem appealing but can lead to inefficiencies. Investing in quality timber can pay off in the long run.

When analyzing costs, consider the durability of the timber. Some types may require more frequent replacements, increasing overall costs. Look beyond the initial purchase price. Maintenance and potential failures can add to expenses. The implications of these decisions can be significant.

Tips: Opt for treated timber for better longevity. Evaluate the specific requirements of your project. Evaluate your budget carefully. Also, do not overlook environmental considerations. Sustainable timber can sometimes offer unexpected cost benefits.

Related Posts

-

How to Use Beam Slab Formwork for Effective Construction?

-

How to Choose the Best Precast Formwork for Your Construction Project

-

Top Benefits of Using Bendy Formwork in Modern Construction?

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

2025 Top Round Column Formwork Techniques and Best Practices Guide

-

Top 10 Things You Should Know About Formwork for Construction Projects