How to Choose the Right Circular Column Formwork for Your Construction Project

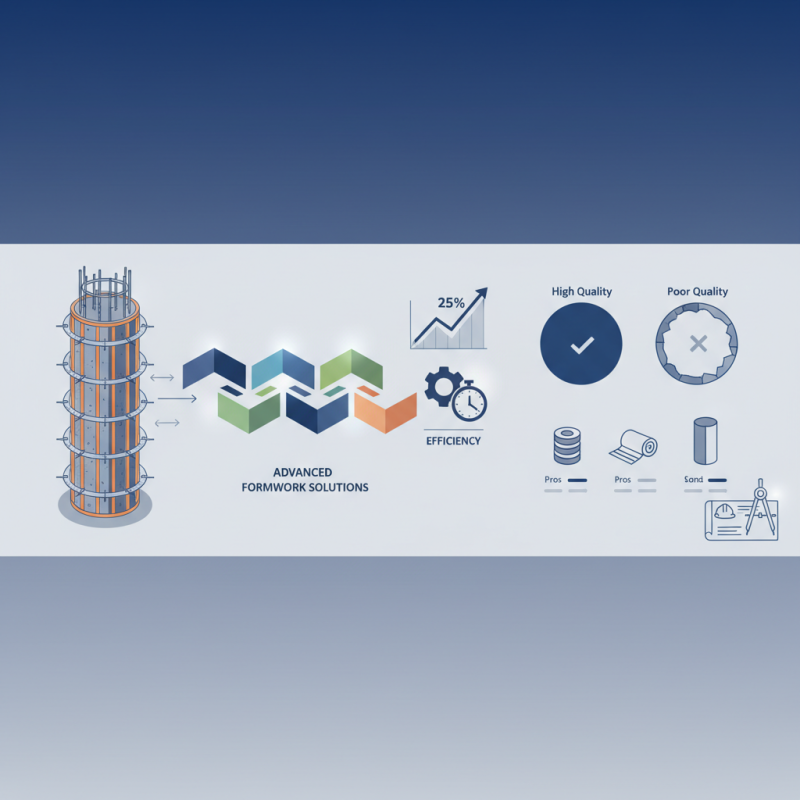

In the ever-evolving landscape of construction, choosing the right circular column formwork is crucial for ensuring structural integrity and efficiency in project execution. According to a report by the International Journal of Construction Management, the demand for advanced formwork solutions has surged by 25% over the last five years, indicating a significant shift towards more innovative construction practices. Circular column formwork, specifically, has become increasingly popular among contractors due to its ability to streamline the construction process and improve accuracy in shaping concrete structures.

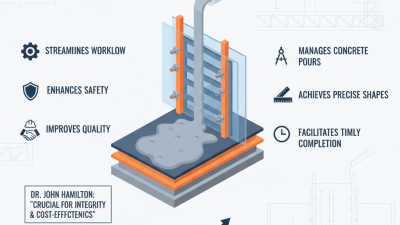

Industry expert Dr. John Thompson, a renowned structural engineer, emphasizes the importance of selecting the appropriate formwork, stating, "The right circular column formwork not only enhances the speed of construction but also ensures that the final product meets the stringent quality standards of modern architecture." As projects demand greater efficiency and faster turnaround times, contractors must critically assess their options when it comes to formwork materials and designs. Understanding the various types of circular column formwork available, along with their unique advantages and limitations, is essential for professionals aiming to deliver successful construction projects.

Factors to Consider When Selecting Circular Column Formwork

When selecting circular column formwork for your construction project, there are several key factors to consider to ensure optimal performance and efficiency. First, assess the specific requirements of your project, such as load-bearing needs and the environmental conditions at the site. Understanding the structural demands will help you choose formwork that can support the concrete's weight while withstanding external pressures.

Materials used in formwork design are also crucial. Options such as steel, aluminum, or timber each offer different benefits in terms of durability, weight, and ease of assembly. Consider the cost-effectiveness of each material, as well as their ability to provide smooth finishes for the columns. Additionally, ease of transportation and storage can influence the choice of formwork, particularly for larger projects that require multiple units.

Tips:

- Always conduct a thorough site evaluation before finalizing your formwork choice. Take note of any unique site challenges that may affect installation and performance.

- Look for formwork systems that offer adjustable features to accommodate varying column sizes and shapes, ensuring versatility across different structural components.

- Collaborating with experienced contractors can provide insights into practical considerations, enhancing the overall decision-making process regarding formwork selection.

Types of Circular Column Formwork Available in the Market

When selecting circular column formwork for construction projects, understanding the different types available is essential for making an informed decision. Generally, circular column formwork can be categorized into three primary types: traditional plywood formwork, plastic formwork, and modular system formwork. Each type has unique advantages and can cater to specific project requirements.

Traditional plywood formwork is a popular choice due to its versatility and adaptability. It allows for custom shaping and can be easily modified to fit various specifications. However, it tends to be heavier and may require more labor for setup.

Plastic formwork offers a lightweight and durable option, which is especially beneficial for projects needing to propel speed and efficiency. This type is often reusable, making it a cost-effective solution in the long run.

Lastly, modular system formwork provides standardized components that can be quickly assembled and disassembled, significantly reducing the time and labor required on-site.

Tips: When choosing the right formwork, consider the project’s specific needs such as the size of the columns, the required finish, and the timeline. It's also advisable to discuss the formwork options with your construction team to ensure that the selected type aligns with your overall project goals and budget. Additionally, evaluate how each formwork type impacts labor costs, as more complex systems may require skilled labor for installation.

Evaluating the Material Options for Circular Column Formwork

When evaluating the material options for circular column formwork, it's essential to consider the project’s specific requirements, including load-bearing capacities, environmental conditions, and cost-effectiveness. Common materials for circular column formwork include timber, steel, aluminum, and composite materials, each bringing unique advantages and drawbacks. According to a report by the International Journal of Project Management, steel formwork, while generally more expensive upfront, can lead to savings in labor and reusability rates that reach up to 80%. On the other hand, timber formwork remains a popular choice for smaller projects due to its ease of handling, despite being less durable and having a limited lifecycle.

Tips for selecting the right material include assessing the longevity and expected number of uses for the formwork. For instance, if the construction project requires frequent reuse, investing in steel or composite materials can provide significant cost savings in the long run. Additionally, consider the environmental impact of your chosen material; composite formwork can offer the advantage of being lightweight and resistant to weather conditions, reducing transport costs and the carbon footprint associated with construction.

Moreover, it's advisable to factor in the skill level of the workforce. As noted in a study by the Construction Management Association, skilled labor can efficiently work with complex formwork systems, which might justify the use of more advanced materials like aluminum. Carefully analyzing these factors will ensure optimal performance and economic efficiency throughout the construction process.

How to Choose the Right Circular Column Formwork for Your Construction Project

| Material Type | Weight (kg/m2) | Cost (per m2) | Durability (years) | Ease of Use |

|---|---|---|---|---|

| Steel | 30 | $80 | 20+ | Moderate |

| Aluminum | 20 | $120 | 15 | Easy |

| Plastic | 15 | $50 | 10 | Very Easy |

| Wood | 25 | $60 | 5 | Difficult |

Understanding Cost Implications in Formwork Selection

When selecting circular column formwork for a construction project, understanding the cost implications is crucial. The initial investment in formwork can significantly impact the overall budget. Factors such as material choice, design complexity, and rental versus purchase decisions must be examined. High-quality materials may come with a higher upfront cost, but they often provide better durability and ease of use, potentially leading to savings in labor and repair expenses over time.

Additionally, the choice of formwork can influence the project timeline, which is directly related to labor costs. More efficient formwork solutions may facilitate faster assembly and disassembly, reducing the time workers need to be on site. It's essential to consider not just the immediate costs, but also how these selections can affect the long-term financial health of the project. A comprehensive cost analysis should account for both direct expenditures and indirect savings when evaluating formwork options, ensuring that the selected solution aligns with the project's financial objectives while meeting performance requirements.

Cost Implications of Circular Column Formwork Selection

Best Practices for Installing Circular Column Formwork

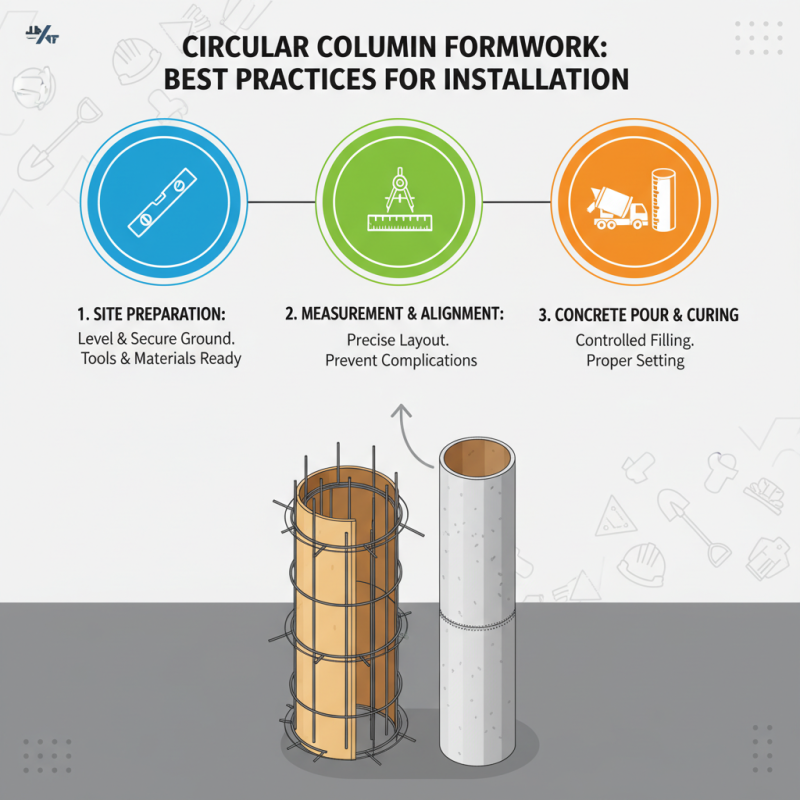

When it comes to installing circular column formwork, adhering to best practices is critical to ensuring structural integrity and efficiency. First and foremost, it is essential to prepare the site adequately. This includes verifying that the ground is leveled and secure, as well as ensuring all necessary tools and materials are on hand prior to beginning the installation. Proper measurements and alignment must be taken before the formwork is set, as inaccuracies can lead to complications during the pouring of concrete and may compromise the final structure.

Once the site is prepared, assembling the formwork requires a systematic approach. Begin by carefully aligning the individual panels to create a seamless circular shape. Utilize rigid connections to hold the panels together and prevent any movement that could lead to leaks. It is also advisable to use bracing to enhance stability during the concrete pouring process. Regularly monitor for any signs of stress or misalignment as the concrete is added; making quick adjustments can prevent more significant issues later on. By following these best practices, you can ensure that the circular column formwork aids in achieving the desired outcome of your construction project.

Related Posts

-

Top Benefits of Circular Formwork for Construction in 2025

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

How to Choose the Right Precast Concrete Formwork for Your Project

-

Why Bulkhead Formwork is Essential for Successful Construction Projects

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

How to Choose the Right Steel Formwork for Your Construction Project