How to Choose the Best Cement Formwork for Your Construction Project?

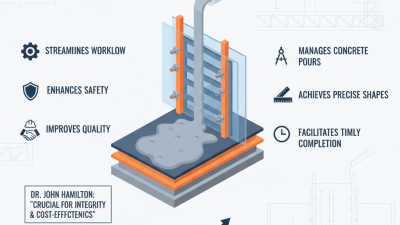

Choosing the best cement formwork is essential for any construction project. The right formwork can significantly impact durability and cost-effectiveness. According to a recent report by the Global Concrete Formwork Market, the market is projected to grow at a CAGR of 8.3% between 2023 and 2030. This growth reflects the increasing demand for reliable and efficient construction methods.

Cement formwork options vary widely in design and material. Steel and aluminum formwork offer robustness and reuse, while timber is often less expensive. However, wood can lead to inconsistencies in quality over time. It's important to consider both the initial cost and lifecycle expenses. An improperly chosen formwork can result in costly delays and structural issues.

Evaluating project specifics is crucial. Factors include the type of concrete mix, environmental conditions, and project scale. Construction players must reflect on these elements to avoid pitfalls. Solutions must balance quality and budget. Understanding these dynamics is vital for successful project outcomes.

Understanding Cement Formwork Types and Their Applications

Cement formwork plays a critical role in construction projects. Understanding the different types of formwork can help you make informed decisions. There are several types available, such as traditional timber, steel, and modular systems. Each type has its own unique advantages and disadvantages.

Timber formwork is often favored for its flexibility and cost-effectiveness. However, it may not always offer the durability required for high-stress applications. Steel formwork, on the other hand, provides greater strength and longevity. It significantly reduces the construction time, but it can be quite expensive. Modular systems often allow for quick assembly and disassembly, making them ideal for repetitive projects. Yet, they may require more initial planning.

Incorporating the right formwork can be challenging. Selection should consider project size, budget, and timeline. Mistakes in the choice of formwork can lead to delays and cost overruns. Evaluating the specific needs of your project is essential. Don’t overlook the importance of proper maintenance for whichever type you choose. Each has its learning curve, and some trial and error may be necessary.

Evaluating Material Options: Steel, Aluminum, and Timber Formwork

When selecting formwork for your construction project, material choice is crucial. Steel formwork offers high durability and strength. It can withstand heavy loads and is reusable. However, it requires proper maintenance to prevent rust and corrosion. Its initial cost may be higher, which is worth considering for long-term projects.

Aluminum formwork is lightweight and easy to handle. It speeds up construction time significantly. However, it might not be as strong as steel for certain applications. Its cost can vary based on the project size. You may find it more suitable for smaller jobs, but be cautious of its limitations.

Timber formwork, on the other hand, provides excellent insulation. It's a popular choice for residential projects. It can be shaped easily to fit various designs. Yet, it is less durable compared to metal options and susceptible to moisture. This could lead to problems with warping or degradation over time. Always weigh the pros and cons of each material to make the best choice for your needs.

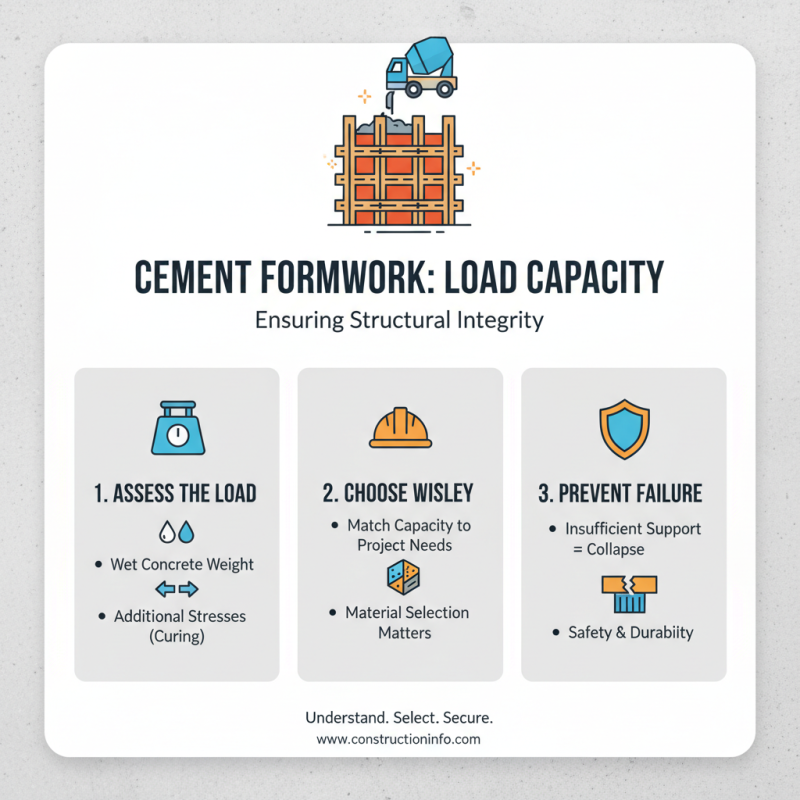

Assessing Load Capacity and Structural Integrity for Safety

When selecting cement formwork, assessing load capacity is crucial. The right formwork must support the weight of wet concrete. Poorly chosen materials can lead to structural failure. It's essential to understand the specific loads your project requires. This includes factoring in the weight of the concrete and any additional stresses during curing.

Additionally, evaluate the structural integrity of the formwork system. Look for signs of wear or weaknesses. A sturdy design is necessary for safety. Regular inspections can help identify issues early. However, decisions can sometimes be rushed, leading to overlooked details. It’s vital to remain diligent and thoughtful in your choices, ensuring that every aspect meets safety standards and performance expectations. Rushing through this phase can lead to costly and dangerous consequences.

Cost Analysis: Budgeting for Formwork in Construction Projects

Budgeting for formwork in construction projects can be challenging. Detailed cost analysis is crucial for managing expenses effectively. According to the American Concrete Institute, formwork typically constitutes 20-25% of total concrete construction costs. Understanding these numbers helps in planning the budget.

Material choice significantly affects costs. Wood, steel, and plastic have varying price points. For instance, plywood may be less expensive upfront but requires more maintenance. Conversely, steel has a higher initial cost but offers durability that can lead to savings over time. Various reports suggest planning for labor costs, which can make up 30% or more of total formwork expenses, adding complexity to budgeting.

Inadequate budget planning can result in project delays and increased overheads. Many contractors fail to account for hidden costs, like delivery fees and waste. The Construction Labor Market Analyzer highlights that poor initial planning can inflate costs by 10-15%. Each decision impacts the project's financial health. Revisiting your formwork strategy could lead to unexpected savings.

Maintenance and Reusability: Long-term Benefits of Quality Formwork

When selecting cement formwork, maintenance and reusability are crucial factors. Quality formwork can significantly reduce long-term costs. Research indicates that effective formwork systems can save up to 30% on labor costs during construction. Proper care extends the life of formwork, allowing for multiple uses across various projects.

Formwork, when maintained correctly, can last for dozens of cycles. A study by the American Concrete Institute reveals that well-constructed formwork can be reused 10 to 20 times before needing replacement. Frequent replacements not only inflate project budgets but also generate unnecessary waste.

However, not all contractors commit to proper maintenance. Some overlook essential cleaning and inspections, leading to costly repairs or replacements. This oversight emphasizes the importance of a thorough maintenance plan. Investing in quality formwork initially may seem higher, but the long-term savings are undeniable. Even small cracks or dents can compromise reliability. It’s vital to reflect on practices that ensure longevity and performance in cement formwork.

Related Posts

-

How to Choose the Right Wall Formwork System for Your Project?

-

Top Benefits of Circular Formwork for Construction in 2025

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

Why Bulkhead Formwork is Essential for Successful Construction Projects

-

How to Choose the Right Circular Column Formwork for Your Construction Project