How to Choose Bendy Formwork for Your Construction Project?

Choosing the right formwork is crucial in any construction project. One option gaining popularity is bendy formwork. Bendy formwork offers flexibility for unique designs. Its adaptability makes it ideal for curvy structures. However, selecting the appropriate type can be challenging.

Consider how bendy formwork interacts with different building materials. Understanding the compatibility can significantly affect your project timeline. Not all bendy formwork options suit every project. There are various types available, each with its pros and cons. A thorough evaluation is essential.

Remember, investing in the right formwork may seem costly upfront. However, the long-term benefits could outweigh these initial expenses. You might face unexpected challenges. But with the right information and planning, you can make an informed decision on bendy formwork.

Understanding Bendy Formwork and Its Applications in Construction

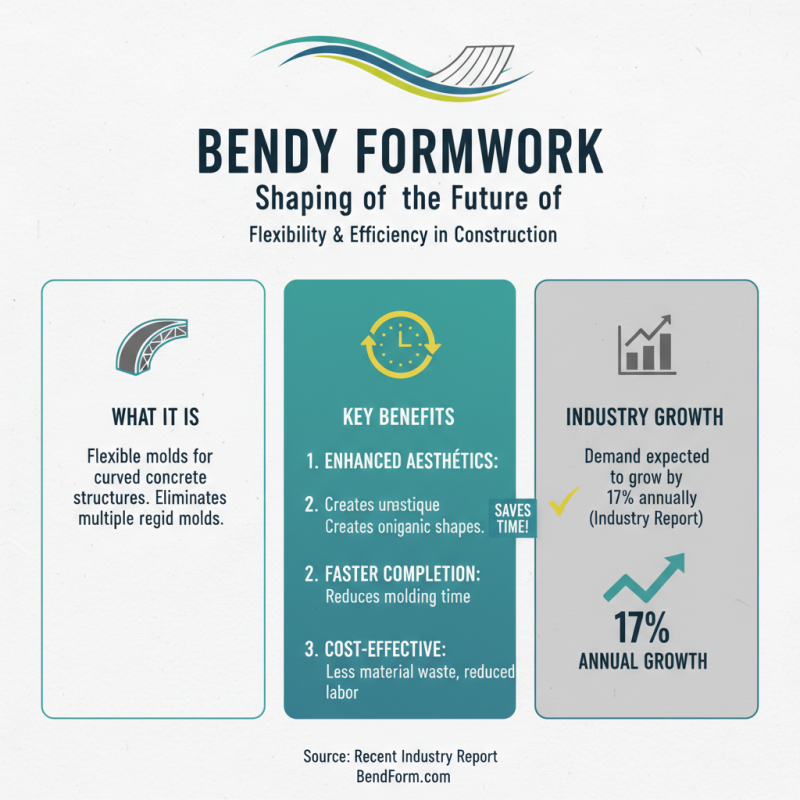

Bendy formwork is gaining traction in the construction industry for its flexibility and efficiency. This type of formwork is instrumental in creating curved structures, enhancing both aesthetics and functionality. According to a recent industry report, the demand for flexible formwork in construction is expected to grow by 17% annually. Bendy formwork can save time, as it reduces the need for multiple molds.

When selecting bendy formwork, consider factors like material type, weight, and ease of installation. Lightweight options are easier to handle, and using eco-friendly materials boosts sustainability. Check site conditions, as they can influence the choice. Inadequate support may lead to issues during pouring.

Tips: Ensure that the formwork is compatible with various concrete mixes. Understand how temperature affects the curing process. Flexibility is essential, but make sure it meets design standards. If you encounter issues, be ready to adjust your plans. It's vital to reflect on past projects to identify areas for improvement. Balancing innovation with tried-and-true methods can lead to better outcomes.

Factors to Consider When Selecting Bendy Formwork for Projects

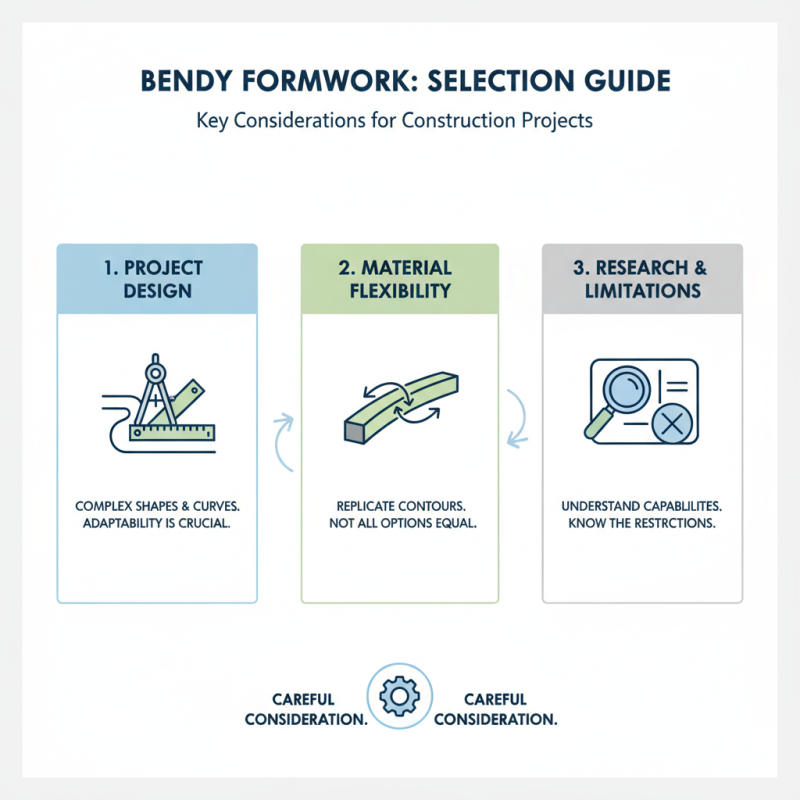

Choosing the right bendy formwork for your construction project requires careful consideration. One major factor is the project's design. Complex shapes often need flexible materials that can adapt easily. Think about the curves or contours that your design entails. Bendy formwork can replicate these forms well, but not all options are the same. Conduct thorough research to understand their limits.

Another important aspect is the material's durability. Will it withstand harsh conditions? Weather impacts construction time and quality. Additionally, the formwork should be reusable. Consider how many times you plan to use it. This can significantly affect your budget and resources. Look for options that may seem compromised at first glance but offer better long-term benefits.

Lastly, think about the ease of assembly and disassembly. Complex systems can lead to delays. Construction sites are busy places. Time is money. You may face unforeseen issues that could complicate the process. Don't overlook this detail. Reflecting on these points will lead to a better decision for your project.

Types of Bendy Formwork and Their Advantages

When it comes to bendy formwork, various types are available, each with unique advantages. Plywood formwork is common for curves due to its flexibility. It adapts easily to different shapes, making it suitable for complex structures. A recent industry report from the Construction Industry Research Board highlights that flexible plywood minimizes waste by up to 30%. This efficiency is crucial for project budgets.

Another option is plastic formwork. It is lighter and easier to handle compared to traditional materials. Plastic options can last longer, reducing replacement costs. They are becoming more popular, especially in urban construction sites, where ease of transport is a key factor. Statistics show that using plastic formwork can accelerate construction by 20%. This speed can be vital in competitive projects.

However, one must consider the drawbacks of different types. Plywood, while flexible, may require more labor for installation. Additionally, plastic formworks can be more expensive upfront. Careful analysis and balance between initial costs and long-term benefits are essential. Not every project can use bendy formwork effectively. Understanding the specific needs of your construction project is critical to making the right choice.

How to Choose Bendy Formwork for Your Construction Project?

| Type of Bendy Formwork | Material | Advantages | Ideal Uses |

|---|---|---|---|

| Plastic Bendy Formwork | Polyethylene | Lightweight, reusable, and flexible | Curved walls and decorative features |

| Steel Bendy Formwork | Steel | Durable, strong, and can support heavy loads | Large commercial projects and bridges |

| Aluminum Bendy Formwork | Aluminum | Lightweight and corrosion-resistant | Residential buildings and landscaping |

| Plywood Bendy Formwork | Plywood | Cost-effective and versatile | Small to medium-sized projects |

Assessing Project Requirements for Bendy Formwork Selection

When selecting bendy formwork for your construction project, understanding the specific requirements is crucial. According to a report by the Construction Industry Institute, improper material choices can lead to up to 30% increases in costs. This underlines the importance of careful assessment.

Evaluate your project dimensions and complexities. Different techniques require specific bendy formwork types. For instance, curved walls may need a tighter radius. A survey found that 18% of projects face delays due to poor material selection. Delays can impact budgets and resource allocation significantly.

Consider the site conditions too. Weather can affect the material's performance. A study showed that 25% of construction time overruns are linked to environmental factors. This prompts the need for adaptable and durable materials. Sometimes, earlier decisions can lead to setbacks. Reflect on both current needs and future modifications in design.

Material Preferences for Bendy Formwork Selection

Best Practices for Using Bendy Formwork in Construction Projects

Bendy formwork offers flexibility in design. It allows for unique shapes and curves, making it ideal for creative projects. However, proper usage is essential. When selecting bendy formwork, consider the materials. Some are more durable than others. Choose based on your project's needs.

When installing, ensure accuracy in measurements. Small errors can lead to significant issues. Secure the formwork properly to avoid warping. It is crucial to monitor the temperature and humidity during curing. These factors impact the final outcome. Remember, flexibility is a double-edged sword.

After pouring, remove the formwork carefully. This process needs attention to detail. An abrupt removal can cause surface damage. Reflect on the challenges you face while working with bendy formwork. Learning from these moments will enhance your future projects. Make adjustments and be prepared for trials. Balancing aesthetics and practicality is vital for success.

Related Posts

-

Top Benefits of Circular Formwork for Construction in 2025

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

Top Benefits of Using Bendy Formwork in Modern Construction?

-

How to Use Beam Slab Formwork for Effective Construction?

-

How to Choose the Right Bracing Formwork for Your Construction Project