How to Choose and Use Adjustable Column Formwork Effectively?

Choosing the right adjustable column formwork is crucial for any construction project. The flexibility of adjustable column formwork allows for efficient and effective construction. However, not all options are suitable for every project.

When selecting adjustable column formwork, consider the specific requirements of your project. Size, load capacity, and ease of assembly are key factors. It is essential to assess the formwork's materials and design. Some designs may get complicated, leading to improper use. Reflecting on these aspects helps to avoid costly mistakes.

Using adjustable column formwork requires careful attention. Proper training for the crew is vital to ensure safety and efficiency. Regular inspections of the formwork before use can identify potential issues. It's important to remember that adaptability in formwork can lead to unforeseen challenges. Overall, thoughtful selection and usage of adjustable column formwork can greatly enhance your project’s success.

Understanding Adjustable Column Formwork: Types and Applications

Adjustable column formwork is a versatile tool in construction. It supports the casting of concrete columns. Different types exist, each serving unique needs. For instance, some allow for height adjustments, while others cater to specific widths and loads. Selecting the right type depends on the project scale and design requirements.

Proper application is crucial. Workers must ensure the formwork is level and securely anchored. This step is vital to prevent shifting during concrete pouring. Mistakes at this stage can lead to uneven columns. Therefore, careful planning and installation matters.

Using adjustable formwork can ease the construction process. However, it also requires meticulous attention to detail. Not all projects will benefit equally from this approach. Some simpler tasks may not justify the complexity. It’s important to reflect on the fittingness of adjustable formwork for each job. Understanding these aspects will lead to more successful outcomes.

Key Factors to Consider When Choosing Adjustable Column Formwork

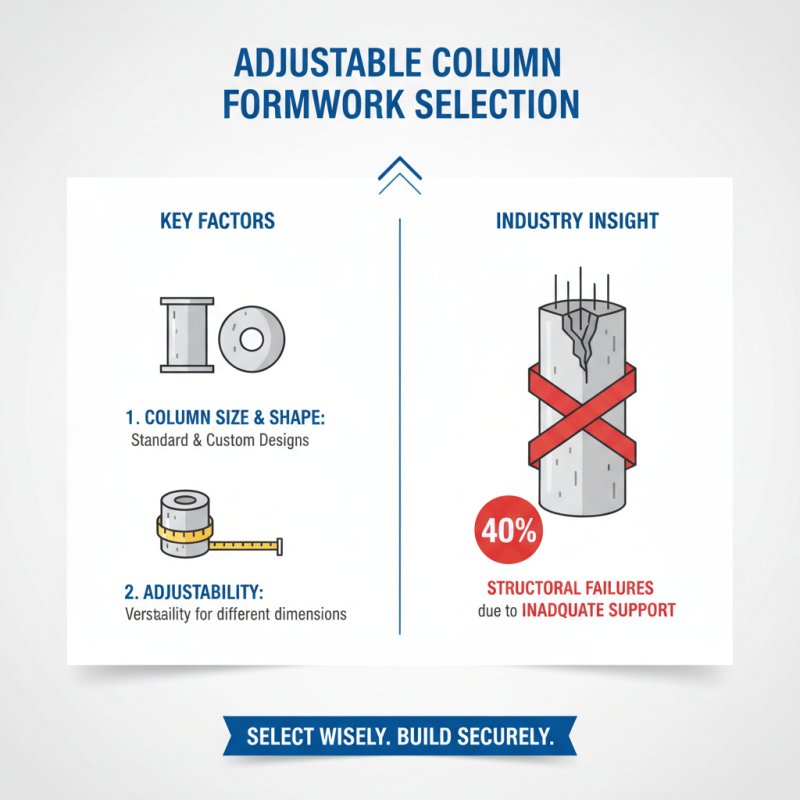

When selecting adjustable column formwork, several key factors come into play. The size and shape of the columns are critical. Ensure that the formwork can accommodate both standard and custom designs. According to industry reports, nearly 40% of structural failures can be traced back to inadequate formwork support.

Material quality is essential. Choose formwork made from durable materials to withstand wet concrete. This reduces the risk of deformation. The formwork's weight also matters. Heavier systems can provide greater stability but are harder to manipulate. Lightweight alternatives can improve efficiency but might lack the same structural integrity.

**Tip:** Always evaluate the formwork against your project specifications. Consider the ease of assembly and disassembly. Provide training for your team to ensure safety.

Adjustable column formwork can sometimes seem cumbersome. Mistakes in setup can lead to delays. Review your team’s experience level. Using experienced personnel can mitigate the learning curve.

**Tip:** Document learned lessons on previous projects. This can help in refining future formwork choices. Gathering feedback early keeps you informed and prepared.

Benefits of Using Adjustable Column Formwork in Construction Projects

Adjustable column formwork has become essential in construction projects. Its flexibility offers numerous benefits. For instance, it can significantly reduce material waste and labor costs. A recent industry report noted that efficient use of adjustable formwork can lower expenses by up to 30%. This is crucial as tight budgets weigh heavily on project managers.

Using adjustable column formwork improves construction speed. Projects can see a reduction in timeframe by approximately 20%. Faster erection and stripping times contribute to this efficiency. However, improper installation can still occur. Workers need to be trained adequately to mitigate risks. Without proper knowledge, mistakes can lead to delays and increased costs.

Tip: Always check for quality before installation. Ensure the formwork is not damaged. Regular inspections also help maintain safety standards.

Another benefit of using adjustable column formwork is minimizing site clutter. With adjustable systems, fewer materials occupy the workspace, leading to a more organized site. However, it's essential to consider that excessive reliance on one type of formwork can limit design creativity. In some cases, mixing formwork types may provide a better solution.

Tip: Evaluate your project’s specific needs. Consider both the pros and cons of using adjustable column formwork. This reflection will yield better outcomes.

Benefits of Using Adjustable Column Formwork in Construction Projects

Best Practices for Installing and Maintaining Adjustable Column Formwork

Adjustable column formwork is essential for efficient construction projects. Proper installation begins with ensuring all components are compatible. Misaligned components can cause structural weaknesses. It is crucial to follow manufacturer guidelines meticulously. The construction industry reports that up to 30% of delays stem from formwork issues. Careful attention to detail during setup can help mitigate these risks.

Maintenance is equally vital to the longevity of adjustable column formwork. Regular inspections help identify wear and tear. Lubricating moving parts and checking for damages should be routine. A study found that poor maintenance can reduce formwork lifespan by up to 50%. This not only incurs additional costs but also jeopardizes safety. Neglecting these tasks can lead to unforeseen problems on the job site.

Real-world examples highlight the importance of effective practices. Experienced contractors often emphasize on-site training for crews. This enhances skills and awareness, reducing errors. However, many teams still overlook this, leading to inconsistent results. Reflecting on these experiences can lead to meaningful improvements in formwork installation and maintenance.

Industry Standards and Safety Guidelines for Adjustable Column Formwork

When it comes to adjustable column formwork, safety should be a top priority. Industry standards highlight the importance of design and material quality. Ensure that the formwork can handle the expected loads. Regular inspections are vital. Identify any wear and tear before use. Adjustments in size and height must be precise, as errors can lead to serious consequences.

Using adjustable column formwork requires careful planning. Each setup must adhere to safety guidelines. Workers should receive training on proper handling and assembly. It's essential to have the right tools for adjustments. A lack of proper tools can lead to mistakes. Keep an eye on the weather conditions too. Rain can weaken materials. It is crucial to avoid working under adverse conditions.

While these guidelines are essential, they don't cover all scenarios. Every construction site has unique challenges. Consider sharing your experiences with others. Reflect on what could be improved during the process. Open communication can lead to better practices. Learning through experience is often where the real lessons lie.

Related Posts

-

Why Is Bracing in Formwork Essential for Construction Success?

-

How to Choose the Right Timber for Concrete Formwork?

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

How to Use Flexible Concrete Formwork for Innovative Construction Solutions?

-

Ultimate Tips for Using Bulkhead Formwork Effectively?

-

How to Use Beam Slab Formwork for Effective Construction?