How to Choose the Right Steel Formwork for Your Construction Project

When it comes to selecting the right steel formwork for your construction project, understanding the intricacies of this critical component is paramount. Renowned industry expert, John Smith, a senior engineer at Global Construction Solutions, emphasizes, "Choosing the right steel formwork is essential for ensuring the structural integrity and efficiency of any concrete construction project." The decision-making process involves assessing various factors such as project specifications, budget constraints, and environmental conditions, all of which play a vital role in determining the most suitable formwork system.

Steel formwork is favored in the construction industry for its durability, reusability, and the precision it offers in shaping concrete structures. As projects become more complex and demanding, the need for an informed selection process has never been more crucial. From high-rise buildings to intricate architectural designs, the formwork system can significantly influence construction timelines and costs. By considering the expert insights and aligning them with project requirements, builders can ensure safety, efficiency, and sustainability in their construction endeavors.

Understanding Different Types of Steel Formwork Available in the Market

When selecting the right steel formwork for your construction project, it's crucial to understand the various types available in the market. Each type serves different purposes and comes with its own set of advantages and limitations. Common types include

- modular formwork, which offers flexibility for various shapes and sizes;

- panel formwork, known for its rapid assembly and disassembly;

- climbing formwork, ideal for high-rise construction due to its efficiency and safety features.

Tips for selecting steel formwork include assessing the project scale and complexity. For larger projects, modular formwork might be more beneficial due to its adaptability. Additionally, consider the local site conditions and the materials available, as these factors can influence the formwork system's effectiveness. Always factor in the ease of transport and installation, as this can greatly reduce labor costs and time.

Another essential tip is to evaluate the formwork's durability and reusability. High-quality steel formwork can be reused multiple times, making it a cost-effective option in the long run. Engage with professionals who can provide insights into the performance of different formwork systems based on past experiences, ensuring you make a well-informed choice that suits your project's unique requirements.

Assessing Project Requirements: Size, Shape, and Load-Bearing Capacities

When selecting the appropriate steel formwork for a construction project, it's crucial to start by assessing project requirements, particularly focusing on size, shape, and load-bearing capacities. According to a report by the American Institute of Steel Construction, properly designed formwork plays a vital role in ensuring structural integrity while minimizing material waste and labor costs. Understanding the project's dimensional requirements is essential. For instance, if you are dealing with large structural elements, such as high-rise buildings, the formwork must be capable of accommodating substantial loads and be configured to support large slab sizes, which can reach up to 20,000 square feet in some commercial applications.

Moreover, the shape of the structure influences the choice of formwork. Complex geometrical designs may require customized solutions, whereas standard shapes can utilize modular systems that are easier to assemble and dismantle. The Construction Industry Institute reports that utilizing adaptable and flexible formwork systems can lead to a reduction in project completion time by approximately 30%, demonstrating that design considerations play a significant role not only in aesthetics but also in project efficiency. Additionally, load-bearing capacities must be meticulously evaluated, ensuring that the selected steel formwork can handle not just the weight of fresh concrete but also any dynamic forces that may occur during construction. This attention to detail in project requirements ultimately contributes to both safety and cost-effectiveness in construction practices.

Evaluating the Quality and Durability of Steel Formwork Materials

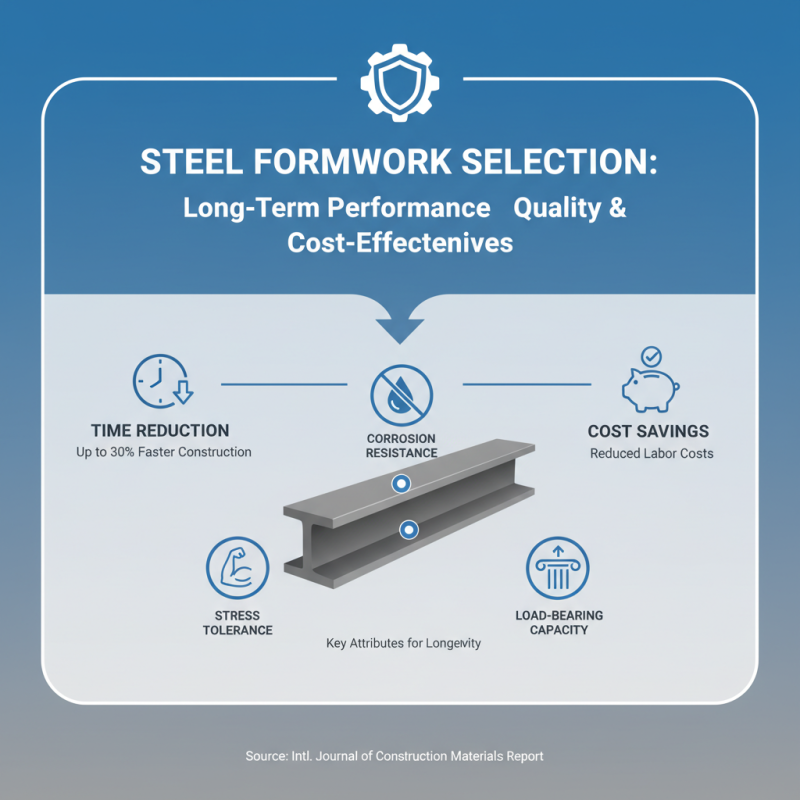

When selecting steel formwork for construction projects, assessing the quality and durability of the materials is paramount to ensure long-term performance and cost-effectiveness. According to a recent industry report from the International Journal of Construction Materials, high-quality steel formwork can lead to a reduction in construction time by up to 30%, which significantly enhances project efficiency and reduces labor costs. Key attributes to look for include corrosion resistance, stress tolerance, and load-bearing capacity, as these factors directly impact the longevity of the formwork.

Additionally, durability is often influenced by the specific steel composition and surface treatment. Research by the Construction Industry Institute indicates that formwork subjected to rigorous testing should possess a minimum tensile strength of 450 MPa and exhibit resistance to warping and deformation under load. Formwork that meets or exceeds these standards tends to perform better over multiple uses, reducing the need for frequent replacements and thereby lowering overall project costs. Investing in robust steel formwork not only ensures better structural integrity during the pouring process but also contributes to sustainable construction practices through extended product life cycles.

Cost Considerations: Budgeting for Steel Formwork Solutions

When budgeting for steel formwork solutions, it is essential to assess not only the initial costs but also the long-term implications of your investment. Steel formwork may have a higher upfront expenditure compared to other materials, but its durability and reusability can result in significant savings over time. Evaluating factors such as project scale, anticipated re-use frequency, and potential resale value after the project can aid in determining the overall cost-effectiveness of steel formwork.

Additionally, consider the associated costs such as transportation, installation, and labor. These elements can often be overlooked but have a substantial impact on the total expenditure. Investing in quality steel formwork may streamline the construction process and reduce the need for frequent repairs or replacements, further enhancing the budget's sustainability. By carefully analyzing these cost considerations, you can make a more informed decision that aligns with both your financial constraints and project objectives.

Cost Considerations for Steel Formwork Solutions

This chart displays the estimated costs associated with different types of steel formwork options for construction projects.

Ensuring Compliance with Safety Standards and Regulations in Construction

When selecting steel formwork for your construction project, adherence to safety standards and regulations should be your primary concern. Safety regulations not only protect the workforce but also ensure the structural integrity of the construction. Familiarize yourself with local and national codes that govern formwork, such as load-bearing capacities and material specifications. Ensuring that your chosen formwork complies with these guidelines helps mitigate potential hazards associated with failures or accidents on site.

Additionally, incorporating safety features into your selection process is crucial. Look for formwork systems that are designed with safety-enhancing elements, such as robust locking mechanisms and guardrails. Regular maintenance and inspections of the formwork are essential to identify worn or damaged parts that could compromise safety.

Training your team on proper use and assembly of formwork can further reinforce safety protocols, creating an environment that prioritizes well-being while ensuring compliance with applicable regulations. By placing safety at the forefront of your decision-making, you not only protect your workers but also contribute to the successful and timely completion of your project.