How to Choose the Right Precast Concrete Formwork for Your Project

The construction industry continually seeks methods to enhance efficiency and reduce costs, making precast concrete formwork increasingly popular among project managers and engineers. According to a recent report from Global Market Insights, the precast concrete market is expected to surpass USD 190 billion by 2025, driven by the growing demand for sustainable and durable building solutions. As more construction projects integrate precast elements, choosing the right precast concrete formwork becomes crucial in ensuring structural integrity and achieving project timelines.

The selection process for precast concrete formwork is influenced by several factors, including project specifications, budget constraints, and environmental conditions. Studies have shown that employing the appropriate formwork can lead to a reduction in labor costs by up to 30% while significantly speeding up the construction schedule. Moreover, a report by the American Concrete Institute highlights the importance of using advanced formwork systems that align with the latest building codes and standards to mitigate risks associated with construction failures. By understanding the distinct advantages and limitations of various precast concrete formwork options, stakeholders can make informed decisions that ultimately enhance the quality and profitability of their projects.

Factors to Consider When Selecting Precast Concrete Formwork

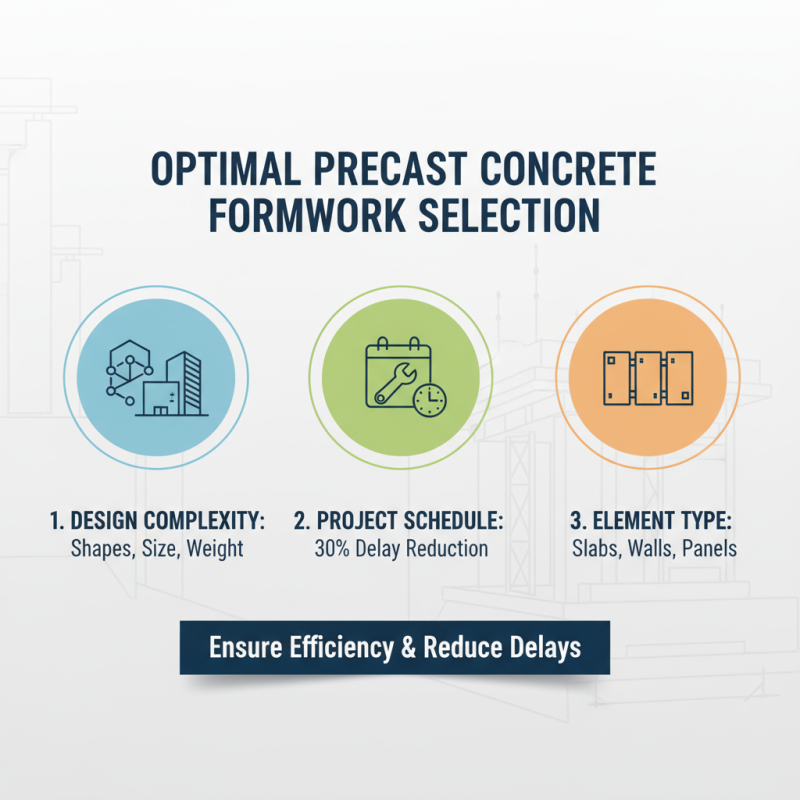

When selecting precast concrete formwork for a construction project, several critical factors must be taken into account to ensure optimal results. First and foremost, the design complexities of the structure will significantly influence the choice of formwork. According to industry reports, approximately 30% of construction delays are attributed to formwork-related issues. Therefore, understanding the architectural and structural requirements—such as the dimensions, weight, and shape of the elements—will determine whether to utilize conventional slabs, walls, or specialized panels.

Another essential consideration is the material properties of the formwork. The selection between steel, aluminum, or plastic formwork can impact the project's efficiency and cost-effectiveness. A study by the Construction Industry Institute revealed that using prefabricated components can reduce labor costs by up to 20%, while also speeding up construction timelines by up to 30%. Additionally, the durability and reusability of the chosen formwork are vital for long-term sustainability, as projects increasingly demand environmentally friendly practices. Formwork that can be reused multiple times not only conserves resources but also leads to significant savings on material costs over the project's life cycle.

Ultimately, evaluating these factors will lead to more informed decisions, enhancing the quality and efficiency of construction, while mitigating risks associated with formwork failure or incompatibility.

Types of Precast Concrete Formwork Available in the Market

When selecting precast concrete formwork for a construction project, understanding the various types available in the market is essential. Precast concrete formwork can be classified into several categories, each with distinct benefits and suited to specific project needs. The traditional formwork systems, which include steel and aluminum forms, are known for their durability and reusability, making them a popular choice for large-scale projects. According to a report by MarketsandMarkets, the global market for precast concrete is expected to grow at a CAGR of 5.3% from 2022 to 2027, driven by the increasing demand for construction efficiency and sustainability.

In addition to traditional formwork, innovative systems such as modular and stay-in-place formwork are becoming increasingly prevalent. Modular formwork consists of pre-engineered panels that can be easily assembled and disassembled, offering flexibility and reduced labor costs. Stay-in-place formwork, often used for walls and slabs, allows for quicker construction times as the formwork remains in place after the concrete is poured. A study by Technavio indicates that the increased adoption of these advanced systems could enhance productivity by up to 30%, reflecting the industry's shift toward more efficient construction techniques. Understanding these options will enable project managers to select the most appropriate formwork type tailored to their construction requirements.

Evaluating Project Requirements for Optimal Formwork Selection

When embarking on a construction project, understanding the specific requirements is crucial for selecting the appropriate precast concrete formwork. Start by assessing the project’s scope, including the design complexity, dimensions, and load-bearing needs. Consider the environmental conditions, such as temperature fluctuations and humidity levels, which can influence curing times and the overall integrity of the concrete. These factors will help narrow down the formwork options by determining the materials and systems best suited for the conditions you expect to encounter.

It is also essential to evaluate the timeline and budget constraints associated with the project. Some formwork systems may offer quicker installation and removal times, thereby reducing labor costs and project delays. Additionally, analyze the lifecycle costs, including reuse potential and maintenance requirements of the formwork. By aligning the project requirements with the capabilities of different precast concrete systems, you can make an informed selection that balances functionality, efficiency, and cost-effectiveness, ultimately ensuring a successful construction outcome.

Cost Analysis and Budgeting for Precast Concrete Formwork

When planning for a construction project that involves precast concrete formwork, budgeting is a critical step that can significantly influence its overall success. An effective cost analysis begins with a thorough understanding of the project's scope and the specific requirements of the formwork needed. This includes factors such as the size and complexity of the structures, the materials used in the precast forms, and the duration of the project. By identifying these variables, project managers can estimate not only the initial costs but also any ongoing expenses associated with the installation and maintenance of the formwork.

Furthermore, considering the life cycle costs of the precast formwork can lead to more informed budgeting decisions. While precast solutions may have a higher upfront cost, they often provide benefits such as reduced labor expenses and shorter construction timelines. Analyzing these factors allows for a more comprehensive view of total project expenditures. Additionally, negotiating with suppliers and exploring rental options for formwork can enable further cost savings. Ultimately, a careful approach to budgeting for precast concrete formwork will help ensure that the project remains financially viable while meeting the necessary structural and aesthetic requirements.

How to Choose the Right Precast Concrete Formwork for Your Project - Cost Analysis and Budgeting for Precast Concrete Formwork

| Formwork Type | Material | Estimated Cost per Square Foot | Weight per Unit | Installation Time (Hours) | Durability Rating (Years) |

|---|---|---|---|---|---|

| Traditional Plywood Formwork | Plywood | $2.50 | 50 lbs | 4 | 5 |

| Steel Formwork | Steel | $4.00 | 100 lbs | 6 | 15 |

| Aluminum Formwork | Aluminum | $5.00 | 70 lbs | 5 | 10 |

| Plastic Formwork | Plastic | $3.00 | 30 lbs | 3 | 7 |

| Modular Formwork | Steel/Aluminum | $6.50 | 85 lbs | 7 | 20 |

Best Practices for Installation and Maintenance of Formwork Systems

When it comes to the installation of precast concrete formwork, adherence to best practices can significantly impact the overall success of a construction project. Firstly, proper alignment and leveling of the formwork are crucial. It is essential to ensure that all components are securely fastened and thoroughly inspected for any signs of damage or wear before installation. Utilizing appropriate shoring and bracing techniques can help maintain the structural integrity of the formwork during the concrete pouring and curing phases. Additionally, it’s important to consider temperature and moisture conditions, as these can affect the setting time and final quality of the concrete.

Regular maintenance is equally important throughout the lifecycle of the formwork system. After each use, clean the formwork thoroughly to prevent concrete residue buildup that can affect future performance. Inspect the formwork for any signs of damage or degradation, and address these issues promptly to avoid compromising safety and efficiency on the job site. Implementing a routine maintenance schedule will extend the lifespan of the formwork, ensuring that it remains reliable for ongoing projects. By focusing on installation accuracy and diligent maintenance practices, construction professionals can maximize the effectiveness and safety of their precast concrete formwork systems.

Precast Concrete Formwork Selection Criteria

Related Posts

-

Top Benefits of Circular Formwork for Construction in 2025

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

What is Plastic Construction Formwork and Its Benefits in Modern Building Projects?

-

How to Choose the Right Steel Formwork for Your Construction Project