What is Cardboard Column Formwork and How is it Used in Construction?

Cardboard column formwork is revolutionizing the construction industry. It offers a sustainable alternative to traditional formwork. Recent studies indicate that over 70% of construction companies are seeking eco-friendly solutions. The lightweight nature of cardboard formwork makes it easy to handle. Additionally, it can reduce overall material costs since it is often less expensive than wood or metal forms.

This innovative solution is made from recycled materials. In fact, a report by the International Journal of Civil Engineering notes that cardboard formwork can cut carbon emissions by up to 40%. Such efficiency is vital as the industry aims to meet sustainability targets. Despite these benefits, some construction professionals still hesitate to adopt cardboard column formwork. Concerns over its durability and load-bearing capacity persist, which requires thorough evaluation.

Yet, advancements in design and technology may address these issues. For example, hybrid systems combining cardboard with other materials are emerging. It is clear that while progress is being made, the journey is not without challenges. The trade-offs between sustainability and reliability must be navigated carefully. As the industry continues to evolve, embracing cardboard column formwork could reshape construction practices for good.

Definition and Overview of Cardboard Column Formwork

Cardboard column formwork is an innovative solution in construction. It offers a lightweight and eco-friendly alternative to traditional materials. This formwork is typically made from recycled cardboard. It can be easily customized to fit various column sizes. The use of cardboard reduces waste and lowers transportation costs significantly.

This formwork technology has been gaining traction in recent years. According to industry reports, construction waste can account for up to 30% of total waste. By utilizing cardboard forms, projects can potentially decrease this figure. Additionally, studies show that using lightweight materials can enhance speed in construction. This can lead to considerable time and cost savings.

However, there are challenges to consider. Cardboard is not as durable as metal or plastic. In wet conditions, it may lose structural integrity. Proper handling and protective measures are necessary during installation. While the adoption of cardboard column formwork is promising, it demands careful planning. The construction industry is evolving, and alternative materials will need to be assessed continuously for their effectiveness.

Materials and Design of Cardboard Column Formwork

Cardboard column formwork is a unique construction solution. It utilizes a lightweight and eco-friendly material to create column structures. The design is generally cylindrical, allowing for easy assembly. This formwork is often made from recycled paper products, contributing to sustainability in construction.

The material is moisture-resistant, which is crucial during the pouring phase. However, it can be sensitive to extreme weather conditions. Proper treatment is necessary to maintain its integrity. The design often incorporates reinforcement patterns or coatings for added strength. Using cardboard column formwork can help streamline the construction process. But, it requires accurate measurements to prevent mishaps.

While innovative, this method has its flaws. Some users report challenges with durability under heavy loads. It may not be suitable for all projects. Designers need to weigh the pros and cons carefully. Effective communication among team members can help address these issues early. Overall, cardboard column formwork presents a fresh approach that merits careful consideration.

Advantages of Using Cardboard Column Formwork in Construction

Cardboard column formwork is an innovative approach in construction. Its advantages are increasingly recognized in various sectors. One major benefit is cost efficiency. Studies indicate that using cardboard formwork can reduce costs by up to 30% compared to traditional materials. Additionally, the light weight of cardboard allows for easier handling and faster assembly on-site.

Environmentally, cardboard formwork stands out. It is primarily made from recycled materials, which lessens the ecological footprint of construction projects. In fact, around 25 million tons of waste are generated by conventional formwork annually. By opting for cardboard, construction companies can significantly reduce waste and contribute to sustainability efforts.

**Tip:** Ensure that the cardboard is treated to resist moisture. Without proper treatment, exposure to rain can compromise its integrity.

Despite its advantages, cardboard formwork may not be suitable for all projects. It's important to evaluate the structural requirements carefully. Some construction sites demand more robust solutions. In such cases, relying solely on cardboard could lead to subpar results.

**Tip:** Always conduct a thorough assessment of the project needs before selecting materials. Taking time to understand the demands of each site is crucial.

Installation Process of Cardboard Column Formwork

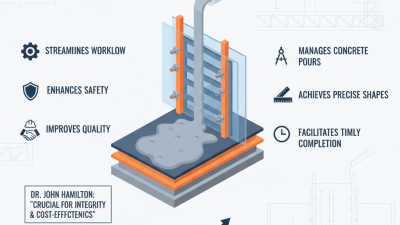

Cardboard column formwork has gained attention in construction due to its eco-friendly nature and efficiency. The installation process is crucial for achieving structural integrity and optimal performance. Begin by assessing the site to ensure a level foundation. Once prepared, assemble the cardboard form panels, ensuring they are properly aligned. This step is critical, as misalignment can lead to structural issues later.

Consider using support braces during installation. These ensure stability while concrete is poured and set. According to industry reports, projects that use cardboard formwork can reduce material costs by 15% compared to traditional methods. However, installation mistakes can negate these savings, leading to costly delays.

Tips: Always check for moisture in the cardboard. Excessive moisture can weaken the form. Additionally, ensure all joints are sealed properly to prevent concrete leakage. Keep an eye on weather conditions too. Rain can damage unprotected forms. Carrying out these steps diligently can enhance both the durability and efficiency of your construction project, saving time and resources.

Cardboard Column Formwork Usage in Construction

Recycling and Environmental Impact of Cardboard Column Formwork

Cardboard column formwork is gaining traction in construction. It's an eco-friendly alternative to traditional materials. Made from recycled paper, it reduces landfill waste. The lightweight nature of cardboard makes it easy to handle on site. Workers can quickly assemble and disassemble columns, saving time. However, the durability of cardboard raises concerns. It may not withstand extreme weather, leading to project delays.

The environmental impact of cardboard formwork is significant. Using recycled materials lowers carbon emissions. This method promotes sustainability in the construction industry. Once the project is complete, cardboard can be recycled again. But not all sites recycle properly. Some operators may overlook proper disposal methods. This could lead to increased waste, counteracting the benefits. Careful education and training are essential. Understanding the recycling process ensures a greener approach. Transitioning to cardboard formwork is promising yet requires responsibility.

What is Cardboard Column Formwork and How is it Used in Construction? - Recycling and Environmental Impact of Cardboard Column Formwork

| Aspect | Details |

|---|---|

| Material | High-quality corrugated cardboard |

| Weight | Lightweight compared to traditional formwork |

| Installation Time | Quick installation within hours |

| Recycling Rate | Up to 90% recyclable after use |

| Environmental Impact | Significantly lower carbon footprint |

| Cost Efficiency | Lower costs compared to traditional formwork |

| Durability | Suitable for various weather conditions |

Related Posts

-

Top Benefits of Circular Formwork for Construction in 2025

-

Top Benefits of Using Bendy Formwork in Modern Construction?

-

How to Use Beam Slab Formwork for Effective Construction?

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

Why Bulkhead Formwork is Essential for Successful Construction Projects