Why Bulkhead Formwork is Essential for Successful Construction Projects

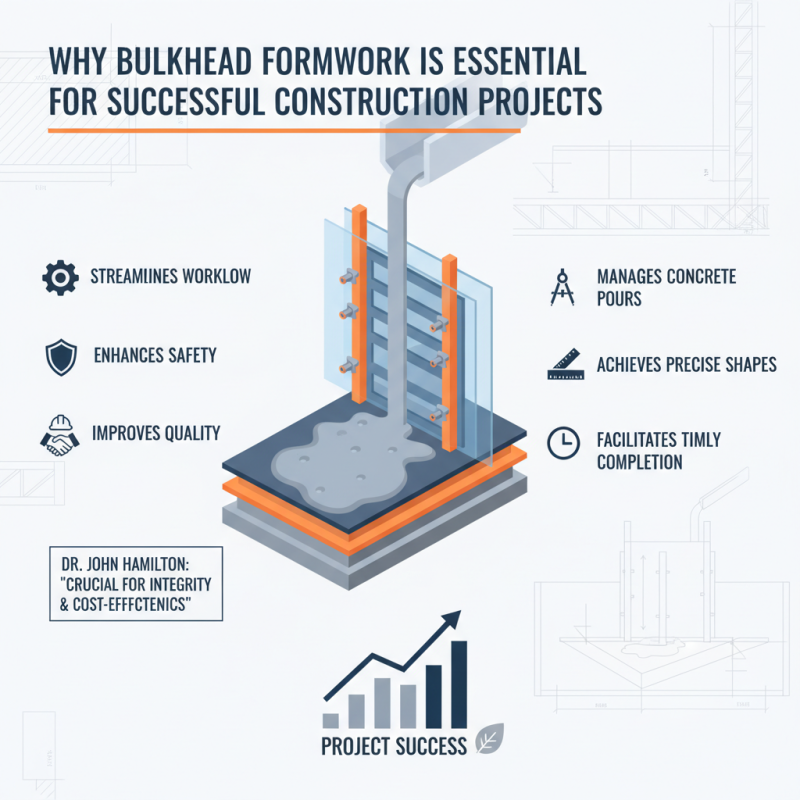

In the realm of construction, the proper execution of projects hinges significantly on the efficiency and reliability of formwork systems. Among various types, bulkhead formwork has emerged as a crucial component in ensuring structural integrity and cost-effectiveness during the construction process. Renowned industry expert Dr. John Hamilton asserts, "Bulkhead formwork not only streamlines workflow but also enhances the overall safety and quality of the structure." His insights encapsulate the essence of why construction professionals must prioritize the use of bulkhead formwork for their projects.

The significance of bulkhead formwork transcends beyond mere functionality; it plays a pivotal role in managing concrete pour heights, achieving precise geometrical shapes, and facilitating timely project completion. With its ability to withstand hydraulic pressure and its adaptability to various site conditions, bulkhead formwork ensures that constructors can tackle complex designs with confidence. As the construction landscape continues to evolve, embracing innovative formwork solutions like bulkhead formwork is essential for achieving successful outcomes and fostering sustainability in construction practices.

The Importance of Bulkhead Formwork in Construction Projects

Bulkhead formwork plays a crucial role in the success of construction projects by providing essential structural support during the pouring of concrete. Designed to hold back concrete and maintain its integrity, bulkhead formwork ensures that the concrete retains its shape until it solidifies. This is particularly important in projects where precise dimensions and structural strength are required. The ability to create strong, defined edges helps prevent any material leakage, ensuring consistency in the finished product.

Moreover, the use of bulkhead formwork increases the efficiency of the construction process. By enabling faster concrete placement and reducing waste, construction teams can save valuable time and resources. The ease of setup and removal of bulkhead systems also allows for quick adjustments on-site, accommodating changes in project design or unforeseen challenges. Overall, the importance of bulkhead formwork cannot be overstated, as it contributes significantly to the safety, quality, and effectiveness of construction projects.

Understanding Bulkhead Formwork: Definition and Purpose

Bulkhead formwork is a crucial component in construction projects, providing structural support and forming elements for concrete work, especially in retaining walls, basements, and other essential structures. Defined simply, bulkhead formwork consists of temporary structures that define the concrete shape before it sets, ensuring accuracy and stability. According to industry reports, the efficiency of bulkhead formwork can enhance construction timelines by up to 30%, significantly reducing labor costs and material waste.

The purpose of bulkhead formwork goes beyond merely shaping concrete. It also plays a vital role in managing hydrostatic pressure, especially in underground applications. Effective bulkhead systems support the integrity of retaining walls against soil and water forces, influencing long-term performance and safety. A study by the American Society of Civil Engineers highlighted that improper formwork could lead to structural failures, causing financial losses estimated at millions of dollars, thereby emphasizing its importance.

**Tips:** When selecting bulkhead formwork, consider using modular systems that adapt to different project specifications. This versatility not only saves time but also cuts down on costs associated with custom fabrication. Additionally, always inspect formwork for any signs of wear or damage before use; maintaining high standards in formwork quality is essential for project safety and success.

Key Benefits of Using Bulkhead Formwork in Construction

Bulkhead formwork plays a crucial role in the construction industry, providing numerous benefits that enhance the efficiency and quality of projects. One of the primary advantages is its ability to create precise and uniform concrete elements. This precision is essential in achieving the desired structural integrity and aesthetics of buildings, as bulkhead formwork allows for exact dimensions and smooth finishes. The use of this formwork system minimizes the risk of defects, such as irregularities in walls and floors, ensuring that the final product meets the highest standards of construction.

In addition to improving quality, bulkhead formwork significantly streamlines the construction process. It facilitates faster pouring and setting of concrete, thereby reducing downtime and labor costs. By offering easy installation and adaptability to various project requirements, bulkhead formwork allows contractors to optimize their timelines and resource allocation. Moreover, its reusable nature promotes sustainability by minimizing waste and decreasing the need for new materials on multiple projects. Ultimately, these benefits make bulkhead formwork an essential component for successful construction outcomes, contributing to both efficiency and excellence in the field.

Best Practices for Implementing Bulkhead Formwork Techniques

When implementing bulkhead formwork techniques, it is vital to follow best practices to ensure structural integrity and project efficiency. One of the key practices involves meticulous planning and design. Accurate measurements and assessments of the site conditions are critical, as they help to tailor the formwork to the specific needs of the project. Using digital modeling tools can significantly enhance the precision of the formwork design, reducing errors and improving the overall workflow on site.

Another crucial aspect is the selection of materials and components for the bulkhead formwork system. Choosing high-quality, durable materials that can withstand pressure and harsh environmental conditions is essential for successful implementation. Additionally, ensuring that all components are compatible and easily assembled will speed up the construction process while minimizing the risk of structural failure. Regular inspections and maintenance of the formwork throughout the project will help identify and address any issues early on, preserving both safety and quality throughout the construction phase.

Common Challenges and Solutions in Bulkhead Formwork Usage

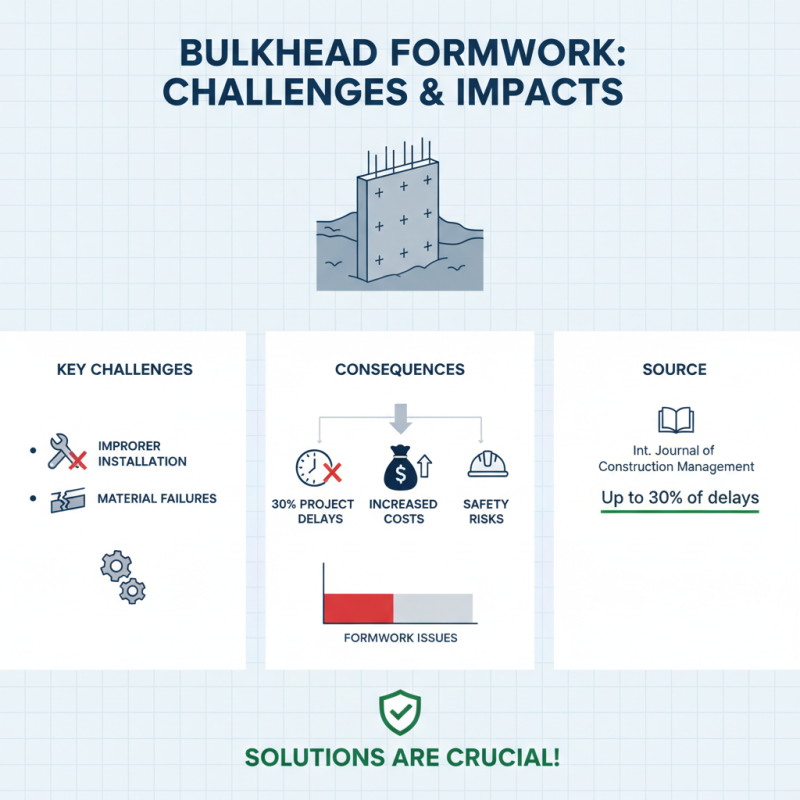

Bulkhead formwork plays a vital role in construction, predominantly in projects requiring extensive earth retention and support systems. However, its usage often encounters several challenges, with improper installation and material failures being prominent concerns. According to the International Journal of Construction Management, up to 30% of construction delays can be attributed to issues related to formwork systems, including bulkheads. Such delays not only inflate project costs but can also compromise safety, making it crucial to address these challenges effectively.

One common issue is the difficulty in ensuring the stability of the formwork under varying soil conditions, which can lead to structural compromise. Engineers often need to implement rigorous soil testing and monitoring to adapt the bulkhead designs accordingly. Additionally, poor communication among teams regarding the design specifications and installation procedures can exacerbate the risk of failure. A report from the American Society of Civil Engineers highlights that a well-defined communication protocol can reduce formwork-related errors by up to 25%. Solutions involve investing in comprehensive training for personnel and adopting advanced monitoring technologies to ensure that the bulkheads meet engineering standards and real-time adjustments can be made when necessary.

Another challenge is the procurement and handling of materials used in bulkhead construction. The performance of these materials can fluctuate based on environmental conditions, which may lead to unexpected delays and variations in quality. The construction industry, as noted in a recent survey by the Building Research Establishment, has shown that proper material selection and pre-emptive quality assessments can enhance the reliability of bulkhead systems, facilitating smoother project execution. Implementing these solutions not only mitigates risks but also contributes to the overall efficiency and success of construction projects, reinforcing the importance of robust bulkhead formwork systems in modern engineering practices.

Related Posts

-

How to Choose the Right Steel Formwork for Your Construction Project

-

Top Benefits of Circular Formwork for Construction in 2025

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

How to Choose the Right Precast Concrete Formwork for Your Project

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects