Why Is Bracing in Formwork Essential for Construction Success?

Bracing in formwork plays a critical role in construction safety and efficiency. According to the National Institute of Standards and Technology, inadequate bracing can lead to structural collapse in 25% of construction projects. This statistic highlights the necessity for robust bracing methods. Industry expert Dr. Robert Caldwell stresses, "Effective bracing in formwork can significantly reduce construction delays and improve overall building integrity." His insights reflect a growing awareness of this essential practice.

While many projects prioritize speed and cost, neglecting bracing in formwork can result in dire consequences. A 2021 report by the Construction Safety Council found that improper bracing led to a 40% increase in repair costs. The visual instability caused by weak bracing can be daunting. Workers often feel anxious if they see formworks swaying or shifting during construction.

Addressing these challenges is vital for successful project completion. Companies must invest in quality materials and training. Recognizing the importance of bracing in formwork is essential, yet many still overlook it. There’s much to reflect on regarding current practices, as ensuring safety should always be a priority.

Importance of Bracing in Formwork for Structural Integrity in Construction

Bracing in formwork plays a crucial role in maintaining structural integrity during construction. It ensures that the formwork remains stable under the weight of wet concrete. Without proper bracing, the formwork can easily collapse. This can lead to costly mistakes and delays. Workers must understand the importance of secure bracing. A single failure can jeopardize an entire project.

Formwork serves as the mold for concrete structures. It can be affected by various forces, like wind or vibrations from machinery. Properly installed braces can distribute these forces evenly. This distribution helps avoid unwanted movement. However, not all bracing methods are equally effective. Each project presents unique challenges. Builders need to critically assess their bracing strategies for effectiveness.

Sometimes, workers may overlook the need for adjustments as the project progresses. This can be a huge oversight. Regular checks are essential to ensure everything is secure. It is vital to make corrections promptly. A successful construction project relies heavily on the reliability of bracing in formwork. Thinking through the bracing design is as important as the concrete mix itself.

Importance of Bracing in Formwork for Structural Integrity in Construction

Types of Bracing Solutions and Their Applications in Formwork Systems

Bracing is a crucial element in formwork systems. It provides stability, ensuring structures remain secure during construction. Without proper bracing, the risk of collapse increases, leading to project delays and safety concerns. Different bracing solutions exist, each suited for specific applications.

Diagonal braces are effective for walls, providing lateral support. They help resist forces that might cause distortion. However, installing them can be tricky. Misalignment can weaken their effectiveness. Vertical bracing, on the other hand, supports the weight of the formwork itself. Workers must ensure it is properly anchored to avoid any failures.

In some cases, adjustable bracing is used. This allows for flexibility in varying conditions. While useful, the adjustments require careful monitoring to maintain stability. Regular inspections are necessary. Each type has pros and cons, emphasizing the need for thoughtful planning and execution. Balancing these aspects can be challenging but is essential for construction success.

Impact of Bracing on Cost Efficiency and Project Timelines in Construction

Bracing in formwork is key to a project's success. It ensures stability during construction. According to the Construction Industry Institute, poorly braced structures can lead to failures, risking time and money.

Cost efficiency significantly improves with proper bracing. Projects can face delays due to weak support systems. A study shows that about 30% of construction delays arise from structural failures. This can inflate budgets by up to 20%. Investing in quality bracing pays off in the long run. It minimizes risks and avoids costly rework.

Project timelines are also directly impacted. Research by McKinsey highlights that projects with efficient bracing complete 15% faster. Delays often lead to increased labor costs and missed deadlines. Thus, bracing is not just a technical necessity. It is a critical element for project planning and execution. Keeping all teams informed about bracing requirements can streamline workflows. Though sometimes overlooked, it deserves attention and detail to avoid major pitfalls.

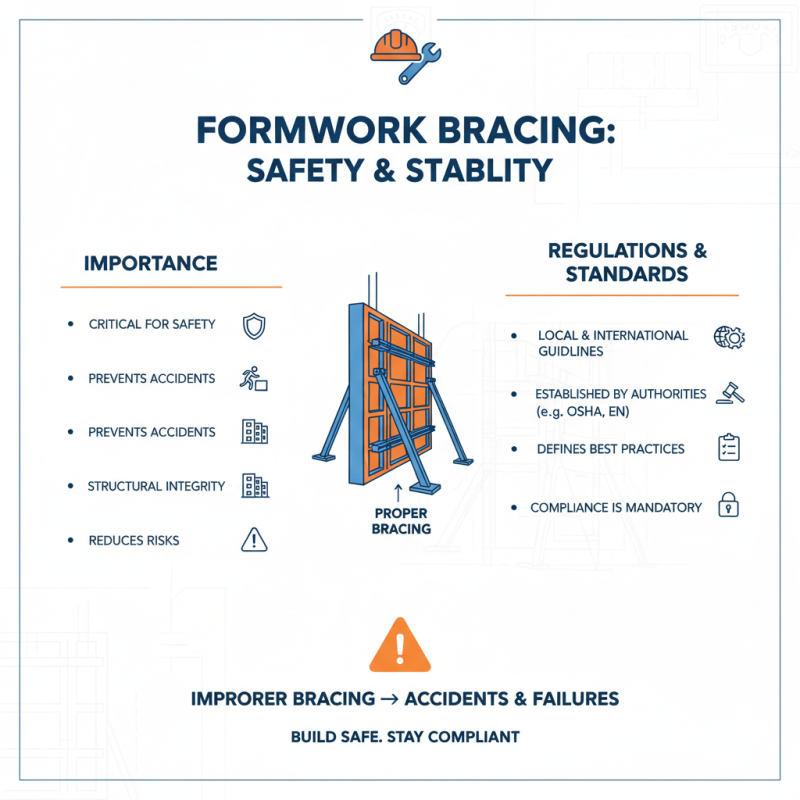

Safety Standards and Regulations Governing Bracing in Formwork Practices

Bracing in formwork is critical for safety and stability on construction sites. Over time, improper bracing can lead to accidents and structural failures. Regulations exist to ensure that bracing adheres to safety standards. These guidelines are established by local and international bodies. They define best practices to reduce risks during construction projects.

Adhering to these regulations is not just a matter of compliance; it’s about protecting lives. Workers rely on formwork that holds firm under pressure. However, many teams overlook specific details. For example, using insufficient bracing materials can undermine a project. Drafting clear bracing plans is essential yet often poorly executed. Awareness of regulations can drive improvement in safety measures.

Regular inspections and training are necessary. Workers should understand how to identify weak points in bracing. The consequences of neglected bracing can be severe. Unsafe practices lead to costly mistakes and project delays. It’s vital to foster a culture of safety through education and adherence to the regulations. A simple checklist could enhance compliance and safety awareness.

Case Studies Demonstrating Successful Bracing Implementation in Projects

Bracing in formwork is crucial for maintaining structural integrity during construction. It is not just a guideline; it is essential for safety and efficiency. Case studies reveal that projects with effective bracing see fewer delays. They also experience reduced costs related to damages and injuries.

One notable case involved a high-rise building. The team used cross-bracing, which significantly improved the stability of the formwork. When wind pressures increased, the bracing held firm. However, the team found that not all bracing was installed correctly at first. This oversight led to additional inspections and temporary delays. The experience highlighted the need for thorough training on bracing techniques.

Tips for successful bracing include: ensure measurements are precise and regularly check alignment. Also, review the bracing materials used; they can make a difference. Learning from past mistakes is also vital. Teams should debrief after projects to discuss what went well and what didn't. Such reflections help refine future bracing strategies and enhance overall project success.

Why Is Bracing in Formwork Essential for Construction Success? - Case Studies Demonstrating Successful Bracing Implementation in Projects

| Project Name | Location | Type of Bracing | Outcome | Duration |

|---|---|---|---|---|

| Sky Tower | New Zealand | X-Bracing | Increased stability and safety during construction | 12 months |

| Greenfield Residential Complex | California, USA | Diagonal Bracing | Reduced material costs and enhanced load distribution | 8 months |

| City Centre Redevelopment | Sydney, Australia | Shear Wall Bracing | Improved vertical load support and efficiency | 14 months |

| Tech Hub Office Building | Toronto, Canada | K-Bracing | Enhanced earthquake resilience | 10 months |

Related Posts

-

How to Choose the Right Timber for Concrete Formwork?

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

Top Benefits of Circular Formwork for Construction in 2025