2026 Best Wall Formwork Solutions for Efficient Construction Techniques?

Efficient construction techniques are essential in today's fast-paced environment. Among these techniques, wall formwork stands out as a key solution. Its ability to streamline the building process greatly enhances efficiency.

The 2026 best wall formwork solutions focus on innovation and usability. These solutions aim to reduce labor costs and construction time. They provide flexibility, allowing for various designs and dimensions. However, not all wall formwork systems may meet every project's needs. Some options can be costly, and choosing the wrong type can lead to delays.

Exploring the best wall formwork solutions means considering quality and performance. It’s crucial to assess each solution carefully. Understanding the strengths and shortcomings of different systems can guide informed decisions. As technology evolves, so do the capabilities of wall formwork. It requires a proactive reflection on what really works and what doesn't in unique construction scenarios.

Overview of Wall Formwork Solutions in Modern Construction

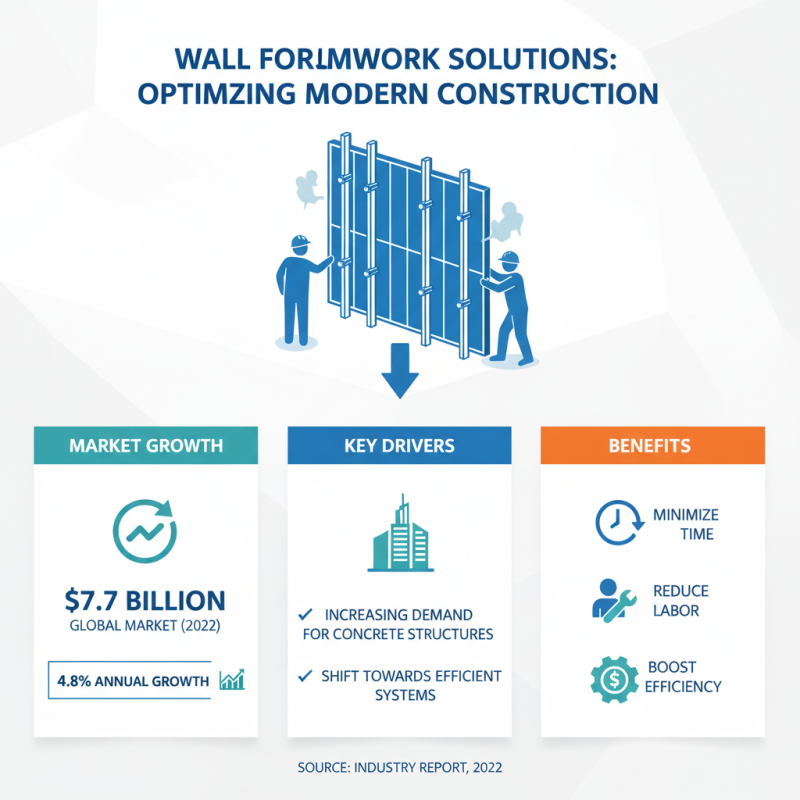

In modern construction, wall formwork solutions play a critical role in optimizing efficiency. The global formwork market reached $7.7 billion in 2022 and is expected to grow by 4.8% annually. This growth reflects the increasing demand for concrete structures. Companies are leaning towards efficient systems that minimize labor and time expenditure.

However, not all formwork solutions deliver the expected results. One significant challenge is the initial investment cost, which can be high for some systems. While advanced materials and technologies promise durability, the procurement process often leaves companies wary. A survey indicated that 40% of construction firms still rely on traditional methods. These methods can lead to wasted resources and project delays.

At the same time, many contractors struggle with the complexity of new systems. Training employees on modern formwork techniques requires time and resources, which some companies cannot spare. This gap leads to inconsistency in quality and performance. Even with the right materials, poor implementation can compromise structural integrity. The industry must address these shortcomings to ensure proper usage of wall formwork solutions.

Key Features of Efficient Wall Formwork Systems

Efficient wall formwork systems are pivotal in modern construction. They enhance productivity while ensuring quality. The latest reports indicate that using advanced formwork can reduce overall project time by up to 30%. This means lower labor costs and faster project completion.

Key features of these systems include ease of assembly. Many newer models allow for rapid setup. This cuts down on the time workers spend adjusting panels. Additionally, many systems are designed for reusability. This leads to cost savings over multiple projects. However, the initial investment can be significant, which raises questions about long-term benefits.

Another important aspect is the material used. Lightweight materials offer easier handling. They also reduce the risk of workplace injuries. Yet, durability should not be compromised. Some lighter systems may not withstand heavy use, necessitating more frequent replacements. Thus, evaluating material choice is essential for sustainable practices in construction.

2026 Best Wall Formwork Solutions for Efficient Construction Techniques

This chart illustrates the efficiency ratings of various wall formwork systems based on key features that enhance construction techniques. The data represents the average efficiency rating, focusing on aspects like speed of assembly, adaptability, and overall cost-effectiveness.

Types of Wall Formwork Technologies and Their Applications

Wall formwork technologies play a crucial role in modern construction. Various types of wall formwork solutions are available to cater to different project needs. Traditional timber formworks are still used in some regions, but their limitations are evident. They can be labor-intensive and lack efficiency in repetitive applications. In contrast, steel and aluminum formworks are gaining traction for their durability and speed. According to a recent industry report, steel formwork can reduce construction time by up to 30%.

The choice of wall formwork greatly impacts project cost and quality. Modular systems allow for rapid assembly and disassembly, which is beneficial for time-sensitive projects. However, these systems come with high initial costs. Many contractors find balancing quality and budget challenging. In fact, 25% of construction delays arise from inadequate formwork planning. Innovations like plastic foam formwork offer lightweight solutions. They are easier to handle but can be less robust.

Environmental considerations are also shaping the future of wall formwork technologies. Sustainable materials are becoming more popular, although they may not always meet performance standards. As construction continues to evolve, the selection of formwork will require careful analysis. Adopting new technologies can improve efficiency, but they also come with their own sets of challenges. The key lies in understanding the specific requirements of each project to select the most suitable wall formwork solution.

Comparative Analysis of Top Wall Formwork Systems for 2026

In 2026, efficient construction techniques heavily rely on advanced wall formwork systems. Recent industry reports suggest that the market for these solutions is expected to grow by over 10% annually. This growth indicates a heightened demand for innovative formwork systems that enhance productivity and reduce overall project costs. Key metrics highlight that properly selected wall formwork can lower labor costs by nearly 30%, which is significant for budget-conscious projects.

A comparative analysis reveals that different wall formwork systems offer varied advantages. Some systems provide rapid setup, allowing for faster construction timelines. Others excel in adaptability, capable of accommodating intricate architectural designs. However, not all systems are equally efficient. A close look at user feedback often uncovers areas for improvement, such as weight limitations and the ease of transport. Manufacturers are pushed to reevaluate their designs continuously to remain competitive in this evolving market.

In addition, durability is paramount. Reports indicate that wall formwork solutions can impact structural integrity. Investing in higher-quality materials may increase upfront costs but could result in long-term savings. Balancing cost and performance remains a critical consideration. As we move towards 2026, the industry must address these challenges while embracing innovative techniques and materials to foster continuous improvement.

2026 Best Wall Formwork Solutions for Efficient Construction Techniques

| Formwork System | Material | Weight (kg/m²) | Typical Use | Cost (€ per m²) | Installation Time (hours) |

|---|---|---|---|---|---|

| Panelized System | Steel | 40 | High-Rise Buildings | 90 | 5 |

| Clamp and Tie | Aluminum | 25 | Residential Buildings | 70 | 3 |

| Modular System | Plastic | 20 | Commercial Buildings | 60 | 4 |

| Lost Formwork | Gypsum | 30 | Temporary Structures | 50 | 6 |

| Sliding Formwork | Steel | 45 | Bridges | 100 | 8 |

Best Practices for Implementing Wall Formwork in Construction Projects

Implementing wall formwork efficiently is crucial for modern construction projects. Proper planning ensures that the structures are built on time and within budget. The selection of materials plays a vital role. Light-weight materials can expedite the assembly process. However, they may not always offer the best durability. This is a challenge that many teams face.

Training the workforce is another key aspect. Workers need to understand how to handle and install the formwork correctly. A lack of experience can lead to mistakes. These mistakes are often costly and can delay the project significantly. Clear communication among team members is essential. Without it, errors are more likely to occur.

Quality checks during the process are necessary, too. Regular inspections help catch issues early. However, teams sometimes overlook this step. They may think that initial setups are sufficient. This can lead to structural problems later. Thus, a continuous review process should be in place. Emphasizing these best practices can lead to more efficient construction outcomes.

Related Posts

-

2025 Top Round Column Formwork Techniques and Best Practices Guide

-

How to Use Beam Slab Formwork for Effective Construction?

-

How to Choose Bendy Formwork for Your Construction Project?

-

10 Best Adjustable Column Formwork Solutions for Your Construction Needs?

-

Why Adjustable Column Formwork is Essential for Modern Construction?

-

2026 Top Trends in Ceiling Formwork Design and Technology?