Top Benefits of Using Bendy Formwork in Modern Construction?

In the evolving landscape of modern construction, the adoption of innovative materials is crucial. Bendy formwork is increasingly gaining recognition for its versatility and efficiency. According to industry expert John Smith, "Bendy formwork redefines how we approach complex shapes in construction." This innovation allows builders to create intricate designs that traditional materials simply cannot achieve.

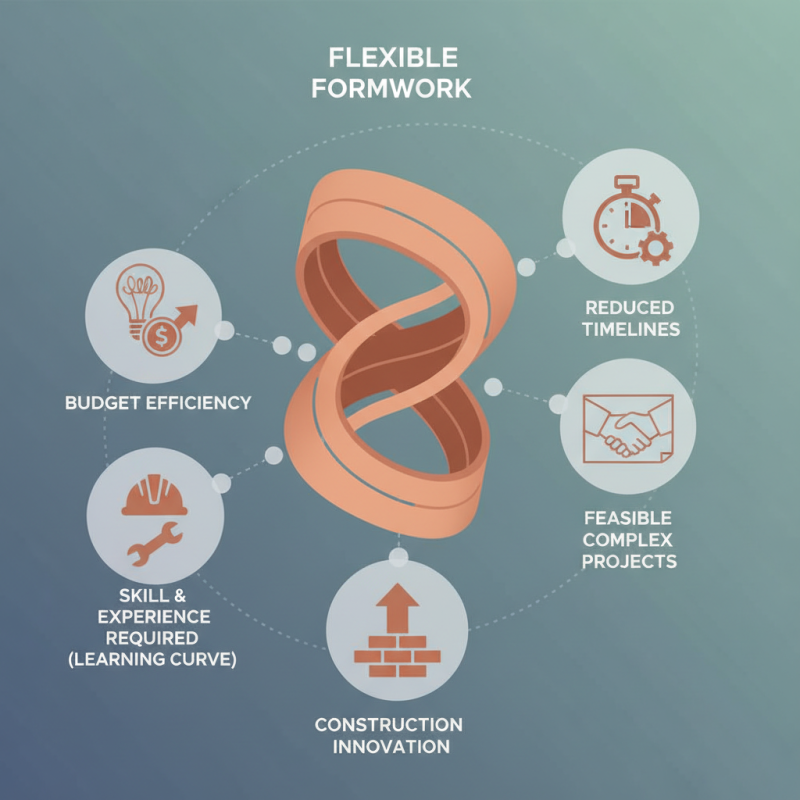

Utilizing bendy formwork can enhance creativity while respecting budget constraints. Projects that once seemed impossible become feasible. It's not without challenges, as mastering this material requires skill and experience. Contractors must invest time in understanding its properties. The learning curve can be steep, but the results often outweigh the difficulties.

As we embrace new technologies, bendy formwork stands out. It can reduce labor costs and improve timelines. Yet, it's vital to reflect on the balance between innovation and practicality. The journey of incorporating bendy formwork invites us to rethink our conventions in construction. The potential for remarkable structures is exciting, but careful implementation remains key to success.

Key Features of Bendy Formwork in Modern Construction

Bendy formwork offers several key features that are transforming modern construction. Its flexibility allows for unique architectural designs. This adaptability reduces material waste. Builders can create curves and angles that were once challenging. The lightweight nature of the formwork also makes it easier to handle. Workers can set up and dismantle it with minimal effort.

Another essential aspect is its durability. Bendy formwork can withstand harsh weather conditions. This means fewer delays in construction projects. It’s also reusable, emphasizing sustainability in building practices. This feature can lower overall costs, making projects more efficient. However, one must consider the learning curve when using this material. Training workers is necessary for optimal results.

Lastly, the ease of customization is noteworthy. Builders can adjust the formwork to meet project specifications. This can lead to innovative designs that enhance aesthetic appeal. Still, one must be careful with decision-making. Rushing through design choices may lead to mistakes. Taking the time to plan ensures better outcomes in the long run.

Top Benefits of Using Bendy Formwork in Modern Construction

This chart illustrates the key benefits of using bendy formwork in modern construction. The data reflects the percentage significance of each benefit based on recent industry surveys.

Enhanced Design Flexibility with Bendy Formwork Systems

The use of bendy formwork systems in modern construction offers remarkable design flexibility. These innovative systems allow for the creation of unique and complex shapes. According to a report by the International Journal of Construction Management, projects using flexible formwork can reduce construction time by up to 30%. This efficiency is crucial in today’s fast-paced construction environment.

Design flexibility, however, comes with its challenges. Not all construction teams are equipped to manage the complexities of bendy formwork. Inadequate training can lead to design errors, resulting in costly adjustments. Furthermore, while these systems provide aesthetic advantages, they may demand more detailed planning and labor input during installation. Projects may face delays if teams lack experience with these techniques.

Nevertheless, the potential rewards are significant. Bendy formwork allows for intricate designs that meet modern architectural demands. The ability to create flowing curves or sharp angles enhances both functionality and aesthetics. A study by the American Concrete Institute highlighted that the use of such systems in building projects often leads to reduced material waste. Adopting bendy formwork could represent a shift in construction paradigms, offering both benefits and hurdles to overcome.

Improved Cost Efficiency through Bendy Formwork Solutions

The demand for cost-effective solutions in construction is ever-increasing. Bendy formwork has emerged as a promising alternative to traditional methods. According to a recent industry report, projects utilizing bendy formwork can reduce labor costs by up to 20%. This efficiency is primarily due to the flexible nature of the material, allowing it to easily conform to various shapes and designs.

Bendy formwork also minimizes waste. Standard formwork often results in leftover materials and discarded sections. Bendy solutions, on the other hand, offer a customizable approach that optimizes material usage. A study indicated that using bendy formwork can lead to a 15% reduction in material waste on average. This is significant, especially in large-scale projects.

However, adopting bendy formwork isn't without challenges. Some construction teams may need training to adapt to these new methods. Initial costs might also be higher compared to conventional options. However, the long-term savings are worth considering. Construction professionals must weigh these factors carefully. The potential for enhanced cost efficiency has caught the industry's attention, sparking interest in further research and development.

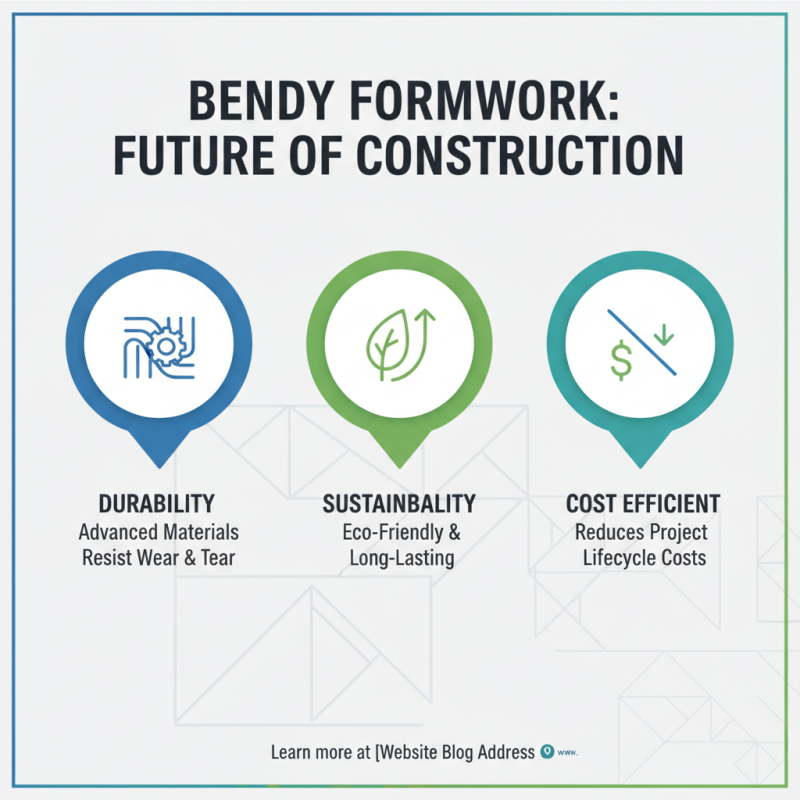

Durability and Sustainability Aspects of Bendy Formwork

Bendy formwork is emerging as a preferred choice in modern construction due to its durability and sustainability features. Made from advanced materials, this formwork can withstand harsh conditions. It resists wear and tear better than traditional materials. A recent industry report noted that using durable formwork can reduce the overall lifecycle costs of a project by up to 15%. This is significant for projects aiming for efficiency.

Sustainability is another critical aspect. Bendy formwork uses less material, which minimizes waste during construction. The ability to recycle or repurpose this formwork adds to its environmental benefits. According to a study from the Construction Industry Institute, buildings using sustainable materials have shown a 20% decrease in energy consumption during their lifecycle. However, some concerns have been raised about the production methods of these materials.

The intricacies involved in manufacturing bendy formwork may not always guarantee eco-friendliness. As the industry advances, it is essential to monitor the sources of raw materials. Challenges also arise in ensuring consistent quality. Not all suppliers adhere to the same standards. Addressing these issues requires ongoing evaluation and commitment to improving practices.

User-Friendliness and Installation Advantages of Bendy Formwork

Bendy formwork is gaining popularity in modern construction. Its user-friendly design simplifies installation and enhances project efficiency. This flexibility allows for creative shapes. Complex designs are more feasible with bendy formwork. It can easily adapt to various surface contours.

Installation is straightforward. Workers can manipulate the material on-site. This reduces the need for extensive training. A shorter setup time means faster project completion. However, workers must be cautious about handling. Improper installation could lead to inefficiencies.

Tips for using bendy formwork effectively: Ensure the surface is clean before installation. Inspect the material for any damage. Proper planning can prevent unexpected issues during construction. Always consider environmental conditions. Adjustments may be necessary in extreme weather. Handling bendy formwork requires care. This is vital for maintaining quality and safety.

Related Posts

-

What is Plastic Construction Formwork and Its Benefits in Modern Building Projects?

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

-

How to Choose the Right Precast Concrete Formwork for Your Project

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

2025 Top Round Column Formwork Techniques and Best Practices Guide

-

Top Benefits of Circular Formwork for Construction in 2025