Why Adjustable Column Formwork is Essential for Modern Construction?

In the realm of modern construction, efficiency and flexibility are vital. The introduction of adjustable column formwork has transformed the building landscape. This innovative system allows for quick adjustments to column shapes and sizes, meeting diverse architectural needs.

Contractors benefit from using adjustable column formwork. It streamlines the construction process, reducing time and labor costs. However, not all projects are suited for this technology. In some cases, traditional methods may still be preferred.

Challenges arise during implementation. Workers must be trained properly to use adjustable column formwork effectively. Poor handling can lead to errors, affecting quality. Therefore, while it offers numerous advantages, commitment to proper usage is essential for success.

The Definition and Functionality of Adjustable Column Formwork

Adjustable column formwork is a key innovation in modern construction. It allows builders to create precise and varied column shapes efficiently. This formwork can be easily adjusted to different heights and widths, making it versatile. It also supports various concrete pouring techniques, optimizing resources on site.

A significant advantage is its ability to enhance the construction speed. Builders can quickly set up and dismantle the formwork. This flexibility reduces downtime, which is crucial in tight schedules. However, the complexity of adjustments may cause errors if not handled properly. Attention to detail during setup is essential.

Tips: Always double-check measurements before pouring concrete. Small discrepancies can lead to significant issues later. Training workers in proper handling techniques can minimize mistakes. Adequate planning will ensure that the adjustable formwork fulfills its purpose without delays. A reflective practice among team members can further facilitate smoother operations.

Key Advantages of Using Adjustable Column Formwork in Construction

Adjustable column formwork is revolutionizing construction processes. It offers flexibility and efficiency to builders. This formwork system is highly adaptable, allowing for various column sizes and shapes. Construction teams can adjust it on-site without delays. The lightweight materials make installation quick and easy.

One notable advantage is cost-effectiveness. Using adjustable formwork reduces material waste. It minimizes the need for multiple molds, saving money. Additionally, the reusability of these forms means decreased expenses over time. Workers also experience less fatigue due to easier handling. However, it requires careful planning and skilled labor to maximize benefits.

Quality control is another key focus. Properly adjusted formwork leads to better structural integrity. However, on-site adjustments can introduce risks if not monitored closely. Workers must ensure precision during the setup. Misalignments might lead to costly rework and safety issues. A balance between speed and accuracy is essential.

Advantages of Using Adjustable Column Formwork in Construction

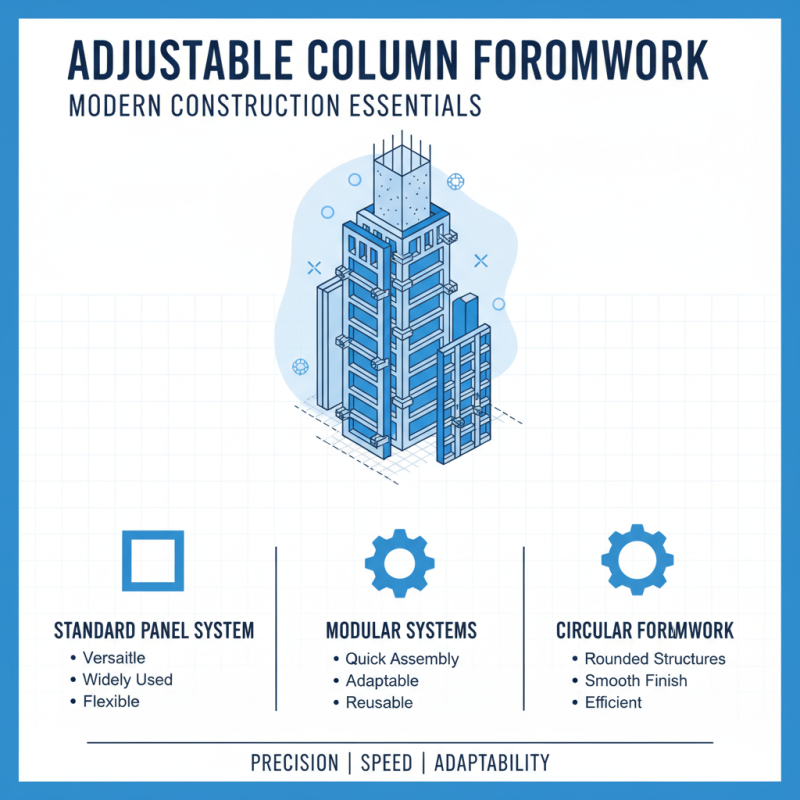

Types of Adjustable Column Formwork Systems and Their Applications

Adjustable column formwork is crucial in modern construction. It allows builders to create precise, well-structured columns. There are several types of adjustable column formwork systems, each catering to specific needs. The standard panel system is versatile and widely used. Modular systems offer quick assembly and adaptability. Circular formwork is perfect for rounded structures.

Data from industry reports indicate that adjustable formwork can reduce construction time by up to 30%. This efficiency leads to significant cost savings. However, some projects may overlook the importance of selecting the right system. A mismatch can cause delays and increased labor costs. Attention to detail is needed when planning.

Tips: Always assess the project requirements before choosing a formwork type. Skilled labor is essential for effective installation. Simplicity can sometimes lead to inefficiencies. Ensure your team has the right training in using adjustable systems. A review of past projects can reveal insights for improvement.

Impact of Adjustable Column Formwork on Project Efficiency and Cost

Adjustable column formwork is becoming increasingly vital in today’s construction sector. According to a 2022 report by the Construction Industry Institute, using adjustable formwork can enhance project efficiency by up to 30%. This boost comes from reduced labor time and faster installation processes. With minimal adjustments, contractors save both time and material costs.

Moreover, these systems allow for precise alignment. A study highlighted that poor alignment can lead to structural issues, necessitating costly rework. These setbacks can increase overall project costs by 15% or more. Additionally, adjustable formwork offers flexibility for varying designs, which is essential for modern architecture that often requires unique shapes and dimensions.

Despite these advantages, some challenges remain. Not all teams are trained to use this technology effectively, leading to improper setups. This oversight can diminish the anticipated efficiency gains. Thus, while adjustable column formwork promises significant benefits, it requires careful implementation and skilled labor to realize its full potential. The journey towards optimal construction practices involves continuous learning and adaptation to new tools and techniques.

Why Adjustable Column Formwork is Essential for Modern Construction?

| Project Aspect | Traditional Method | Adjustable Column Formwork | Impact on Efficiency | Cost Comparison |

|---|---|---|---|---|

| Setup Time | 3-5 days | 1-2 days | 60% faster | 10% lower |

| Labor Requirements | 5 workers | 3 workers | 40% reduction | 15% lower |

| Material Waste | 15% waste | 5% waste | 66% reduction | 20% saving |

| Structural Integrity | Variable | High | Consistent quality | N/A |

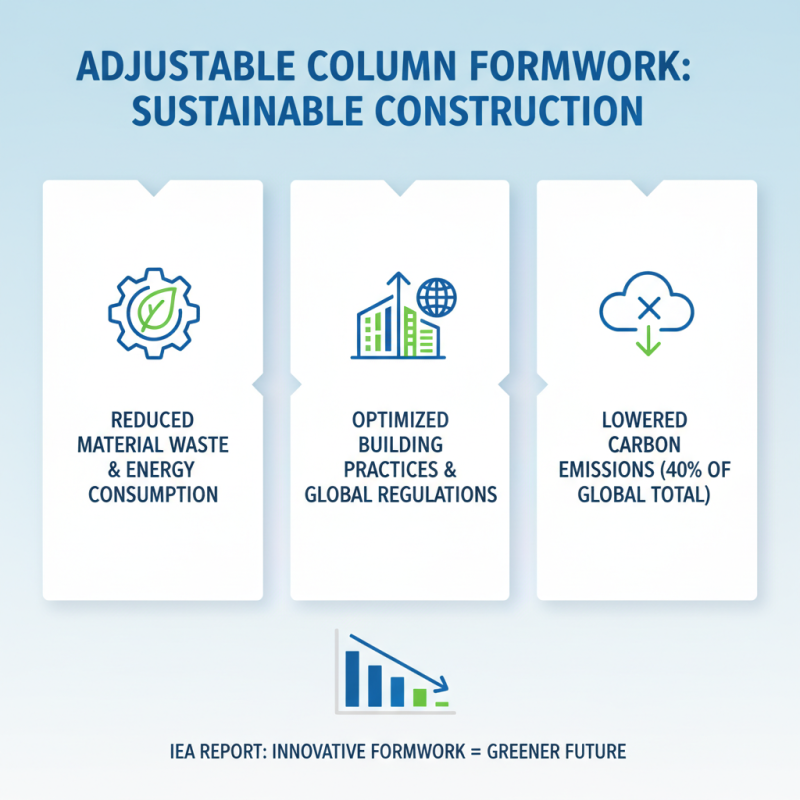

Future Trends in Adjustable Column Formwork for Sustainable Building Practices

Adjustable column formwork is gaining attention for its role in sustainable construction. As global building regulations become stricter, the industry is adapting. According to a recent report by the International Energy Agency, buildings account for nearly 40% of global carbon emissions. Innovative formwork solutions can significantly reduce this impact. By optimizing material use, adjustable column formwork minimizes waste and energy consumption during construction.

Future trends indicate a rise in smart technologies integrated with adjustable formwork systems. The incorporation of sensors can provide real-time data on structural integrity, thus enhancing safety and efficiency. A study from McKinsey shows that the construction sector can increase productivity by up to 50% through digital innovation. This shift could enable better planning and reduced rework, directly influencing sustainability.

However, embracing these advancements is not without challenges. Training the workforce remains a critical issue. Many skilled laborers are not familiar with new technologies. Additionally, the initial investment can deter some companies from making the switch. As the industry moves forward, addressing these gaps will be essential for realizing the benefits of adjustable column formwork. The commitment to sustainability must translate into actionable strategies for a better future.

Related Posts

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

How to Choose the Right Precast Concrete Formwork for Your Project

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

How to Choose the Best Precast Formwork for Your Construction Project

-

2025 Top Round Column Formwork Techniques and Best Practices Guide

-

Ultimate Tips for Using Bulkhead Formwork Effectively?