2026 Top Trends in Suspended Slab Formwork Industry?

The suspended slab formwork industry is evolving rapidly. According to John Smith, a renowned expert in construction technology, “Innovation in formwork is crucial for efficiency.” This statement highlights a vital point as new trends emerge in the field.

In 2026, the top trends will revolve around sustainability, advanced materials, and automation. Builders are searching for cost-effective solutions. They want to reduce waste while improving safety standards. The demand for lightweight systems is also increasing. These trends require a thoughtful approach.

However, not every innovation meets expectations. Some designs may complicate the installation process. Furthermore, cost-effectiveness does not always imply quality. The challenge lies in balancing these factors. Industry professionals must stay informed and adaptable.

Emerging Technologies in Suspended Slab Formwork for 2026

Emerging technologies are rapidly transforming the suspended slab formwork industry as we approach 2026. Innovative materials, like advanced composites, are becoming more common. These materials are often lighter and more durable. Reports indicate that using such materials can reduce overall construction weight by up to 30%. This shift not only improves safety but also enhances overall efficiency on job sites.

Automation is also playing a crucial role. Robotic systems are beginning to assist in the assembly and disassembly of formwork systems. For instance, automated systems can complete tasks in a fraction of the time compared to manual labor. A recent study highlighted that automation can lead to a 15% reduction in labor costs. However, there are still challenges to consider, including the high initial investment in technology.

Furthermore, modular formwork solutions are gaining traction. These systems allow for quicker assembly and realignment on site. Reports suggest that modular approaches can cut construction time by 20% or more. Yet, integration with existing systems remains a hurdle. Companies often face resistance when upgrading outdated methods. This indicates a potential gap that needs addressing to fully realize the benefits of these emerging technologies.

2026 Top Trends in Suspended Slab Formwork Industry

| Trend | Description | Impact Level | Projected Adoption Rate |

|---|---|---|---|

| Prefabrication of Slabs | Increasing use of prefabricated components for quicker assembly and higher quality control. | High | 65% |

| Digitalization and BIM | Integration of Building Information Modeling (BIM) for enhanced design and construction workflows. | Moderate | 50% |

| Sustainable Materials | Shift towards using eco-friendly materials in formwork systems to promote sustainability. | High | 70% |

| Automation and Robotics | Adoption of automated systems and robots to minimize labor costs and enhance safety. | Moderate | 40% |

| Smart Formwork Solutions | Utilizing IoT and sensor technology to monitor and optimize the formwork process in real-time. | High | 55% |

Sustainability Trends Influencing the Formwork Industry

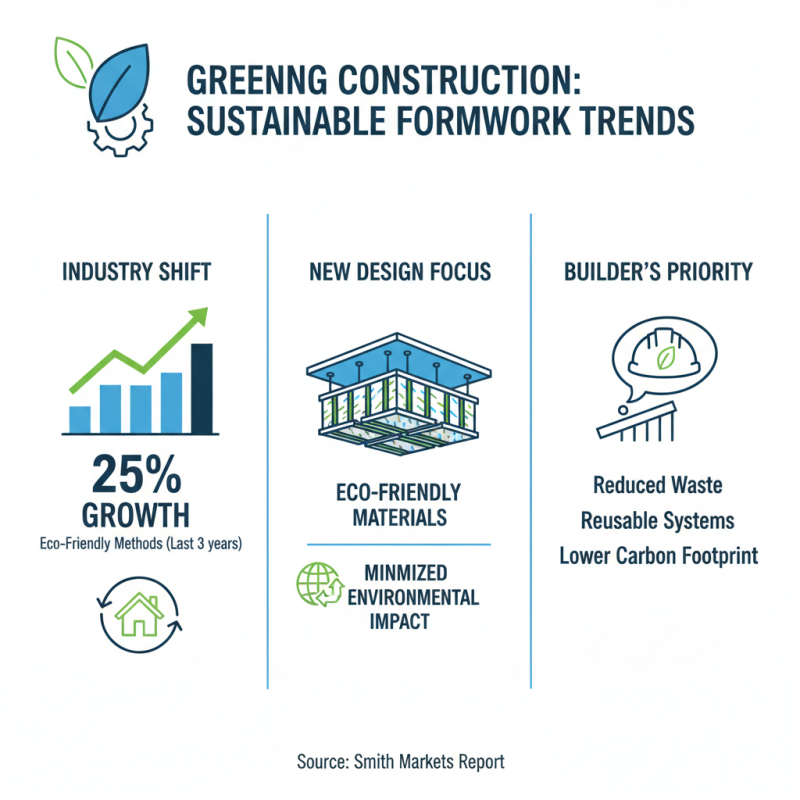

The formwork industry is witnessing a significant shift towards sustainability. According to a report by Smith Markets, the demand for eco-friendly construction methods grew by 25% in the last three years. This trend is reshaping how suspended slab formwork is designed and used. Builders are now prioritizing materials that minimize environmental impact.

Innovative materials, such as recycled plastics and engineered wood, are gaining attention. These options are not only sustainable but also provide durability and strength. Studies show that using such materials can reduce carbon footprints by up to 30%. However, challenges remain. Many contractors still rely on traditional materials that are not environmentally friendly.

Moreover, the push for sustainable practices extends to the entire supply chain. Manufacturers are exploring energy-efficient production processes. A recent industry report highlighted that nearly 40% of manufacturers have adopted renewable energy sources. Yet, the transition is slow. It requires collaboration across various sectors. To truly embrace sustainability, the industry must address these gaps and take bold steps forward.

Design Innovations in Suspended Slab Formwork Solutions

The suspended slab formwork industry is witnessing innovative design trends in 2026. These advancements focus on sustainability and efficiency. New materials are taking the spotlight. Lightweight and durable options reduce transportation costs. They also enhance the overall safety of the construction sites. The integration of modular designs simplifies assembly and disassembly.

Digital technologies are another game changer. 3D modeling improves accuracy in planning and execution. This reduces waste and saves time. However, reliance on tech can also lead to oversights. Workers may face challenges adapting to complex systems. Ensuring adequate training is crucial to overcome these hurdles.

Collaboration among architects, engineers, and contractors fosters creativity. They push the limits of traditional design. Unique, intricate patterns start to emerge in formworks. Yet, not all designs work perfectly. Some may face practical issues on site. Constant evaluation and feedback loops will drive future improvements in the industry.

2026 Top Trends in Suspended Slab Formwork Industry

This chart illustrates the projected growth trends in key areas of the suspended slab formwork industry for 2026. The data reflects the increasing demand for advanced materials, automation in construction processes, and the shift towards sustainable building practices.

Market Dynamics and Growth Projections for 2026

The suspended slab formwork industry is poised for significant growth in 2026. Recent market reports indicate an annual growth rate of around 5% over the next few years. This surge is primarily driven by increasing demand in construction across both commercial and residential sectors. Countries investing in infrastructure projects are expected to lead this trend.

Several factors contribute to market dynamics. A rising population demands more housing, increasing the need for efficient construction methods. Innovations in material technology are helping to enhance the quality of formwork. This advancement reduces costs and improves durability. However, there remains a challenge in managing waste produced during the construction process.

Sustainability is becoming a key focus. The industry is under pressure to minimize environmental footprints. Estimates suggest that green formwork solutions could dominate 30% of the market by 2026. Yet, many companies still lag in adopting these practices. They often prioritize immediate cost savings over long-term gains. Balancing efficiency and sustainability remains a critical challenge as the industry evolves.

Regulatory Changes Affecting the Formwork Sector

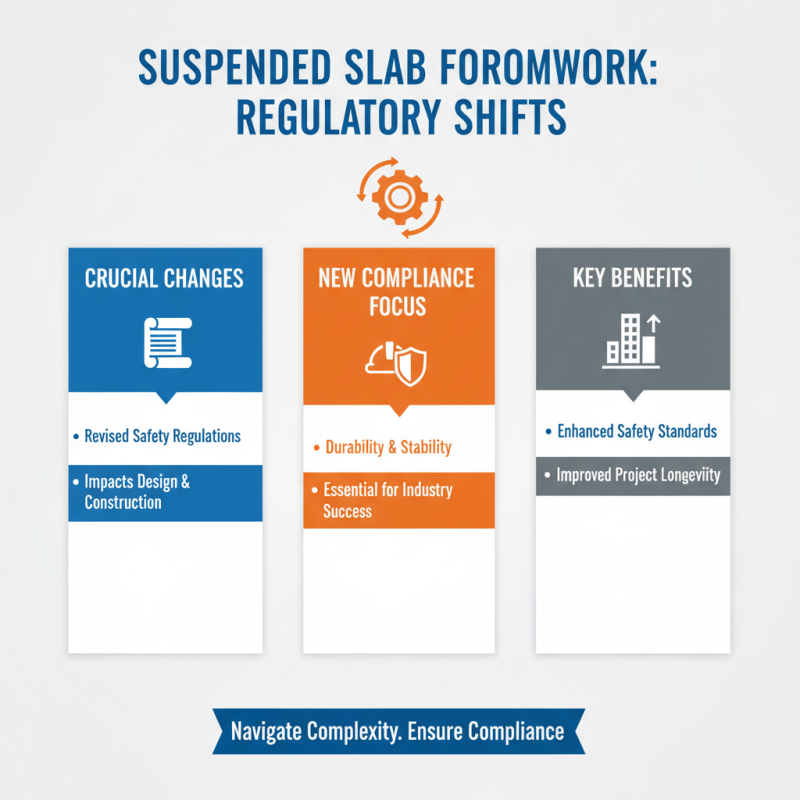

The suspended slab formwork industry is experiencing crucial regulatory changes. These changes significantly impact design practices and construction methods. New safety regulations emphasize durability and stability in formwork systems. Compliance with these laws can be complex but essential for success in the industry.

Tip: Always stay updated on local regulations. They can differ significantly by region. Engage with resources that provide insights on policy changes. This will help avoid costly compliance issues later.

In recent years, sustainability regulations have also emerged. Companies are now encouraged to use eco-friendly materials. Adopting these practices can lead to both environmental and financial benefits. However, transitioning to new materials may result in unexpected challenges. It’s crucial to evaluate whether these changes align with project goals.

Tip: Evaluate the financial impact of switching to sustainable materials. Consider long-term savings against initial investments. Balancing these aspects is not always straightforward, so careful analysis is key.

Related Posts

-

What is Cardboard Column Formwork and How is it Used in Construction?

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

2026 Best Wall Formwork Solutions for Efficient Construction Techniques?

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

2026 Best Plastic Construction Formwork Options for Building Projects?

-

How to Choose the Right Circular Column Formwork for Your Construction Project