2025 Top Round Column Formwork Techniques and Best Practices Guide

The construction industry is evolving, especially in the realm of round column formwork. According to a recent study by the Global Federation of Formwork, the market for formwork systems is projected to grow at a compound annual growth rate of 5.9% through 2025. This significant increase emphasizes the need for innovative techniques and best practices in round column formwork to meet rising demands.

Experts like Dr. Emily Carter stress the importance of using efficient formwork technologies. She notes, "Adopting the right formwork solutions can significantly reduce labor costs and construction time." This insight reflects the current industry focus on improving project efficiency and sustainability. Many construction professionals still grapple with outdated methods, leading to project delays and cost overruns.

Improving round column formwork practices is not merely about implementing new technology. It requires a careful assessment of existing procedures and stakeholders’ roles. While advancements are available, many remain underutilized. Reflecting on past projects can illuminate gaps in technique application and training opportunities. Addressing these issues is crucial as the industry moves towards more streamlined and effective practices.

Overview of Round Column Formwork Techniques

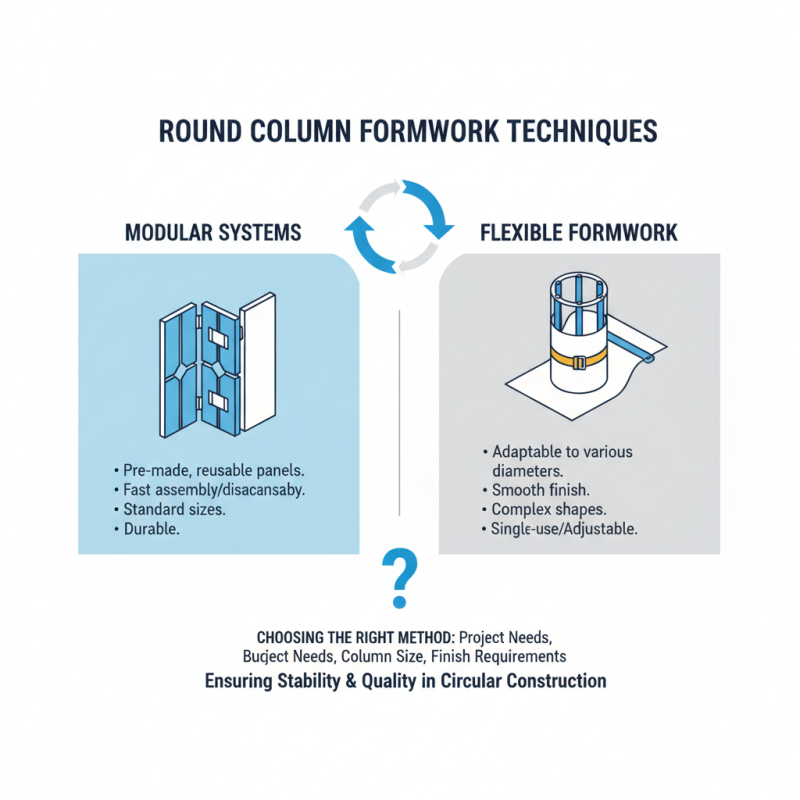

Round column formwork techniques have evolved significantly in recent years. These methods are essential for constructing circular structures like columns and silos. Round columns often require unique approaches to ensure stability and proper finishing. Key techniques include modular systems and flexible formwork. Each has its own set of advantages and drawbacks, making it crucial to evaluate your project's specific needs.

Using modular systems can speed up construction. They allow for precise measurements and quick assembly. Yet, they might not always fit complex designs. On the other hand, flexible formwork provides versatility. It conforms to various shapes and sizes. However, it may demand more labor and skill to manipulate. If not handled correctly, there's a risk of compromising the column's integrity.

The choice between these techniques should reflect the project's requirements. Do you prioritize speed, or is design flexibility your priority? Each technique has learning curves and potential pitfalls. Some projects may face delays due to miscalculations or material issues. Reflecting on past experiences can guide future decisions, improving overall outcomes.

Materials Used in Round Column Formwork Construction

Round column formwork is essential in modern construction. The materials used play a critical role in ensuring structural integrity. Commonly, engineers choose plywood, metal, or composite materials. Each type has unique benefits and drawbacks.

Plywood is cost-effective but may not withstand harsh conditions. Metal forms offer durability but require higher initial investment.

Additionally, composite materials are gaining traction. They are lightweight and can handle complex shapes. However, they often come with a steeper price tag. Construction teams must weigh these options carefully.

Constructors also face challenges with waterproofing and insulation. Using the wrong materials can cause leaks and delays. It is vital to ensure that all components work together seamlessly. Balancing cost, efficiency, and material properties is tricky. Small decisions can significantly impact the project outcome.

Step-by-Step Installation Process for Round Column Formwork

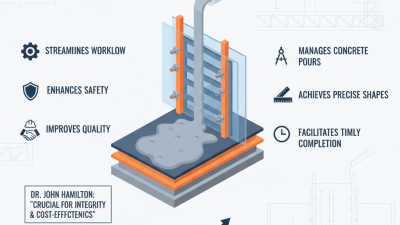

When it comes to installing round column formwork, precision is key. The installation process generally begins with assessing the site conditions. A solid foundation is necessary. Statistics show that approximately 70% of construction delays stem from improper site preparation. Ensuring a stable base can significantly reduce issues down the line.

Next, careful assembly of the formwork is crucial. Misalignments can lead to structural weaknesses. Research indicates that up to 30% of formwork failures are due to poor installation techniques. Workers must pay attention to verticality and ensure all components fit snugly. A meticulous approach not only enhances safety but also promotes efficiency in pouring concrete.

Finally, monitoring the curing process is essential. Inadequate curing can result in cracks or weaknesses in the column. Studies reveal that proper curing can improve concrete strength by as much as 25%. Inadequate attention to detail can compromise the entire project. Using sensors or manual checks can help ensure that the environment is optimal for curing. These steps, while straightforward, demand a commitment to precision and quality at every stage of the installation process.

Best Practices for Maintaining Structural Integrity

Maintaining structural integrity in round column formwork is essential for any construction project. Proper technique during installation can prevent future issues. Regular inspection is crucial. Look for signs of wear or damage. Ensure the formwork is aligned correctly before pouring.

Using the right materials makes a difference. Substandard materials can compromise strength. Pay attention to the environment. Weather changes can affect curing time. It's necessary to adapt the process. For instance, mixing ratios may need adjustments in high humidity.

Mistakes happen, even with the best practices. A slight misalignment can lead to costly repairs. Teams should always double-check their work. Documenting the process can highlight areas in need of improvement. Remember, every project offers a chance to learn. Reflecting on past mistakes fosters growth.

Common Challenges and Solutions in Round Column Formwork

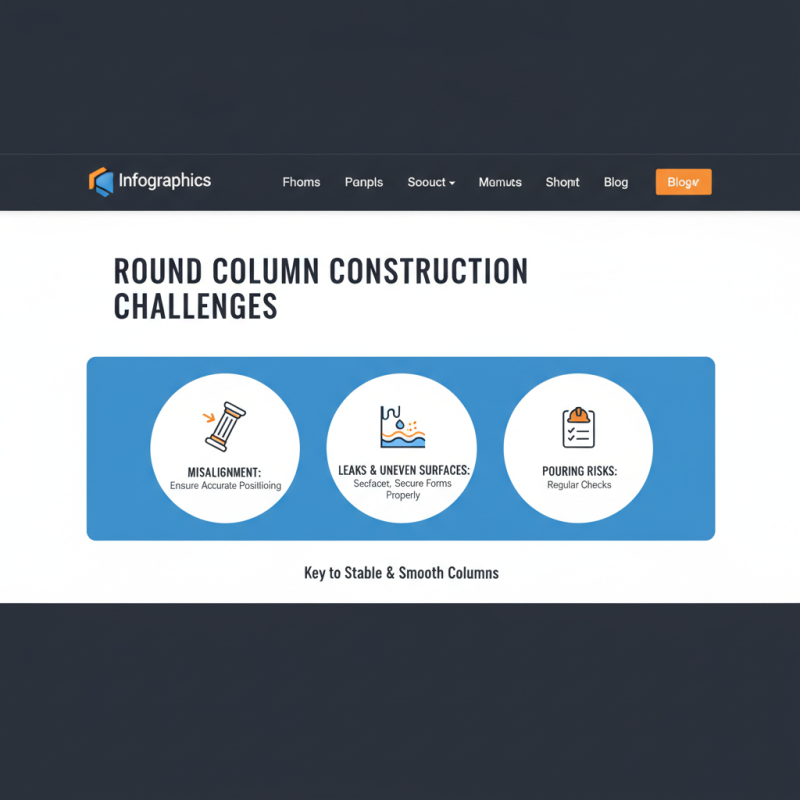

When constructing round columns, several common challenges arise. Misalignment during setup is a frequent issue. Even slight deviations can lead to significant problems later. Contractors must ensure that formwork is accurately positioned. Improperly secured forms can lead to leaks and uneven surfaces. Regular checks during the pouring process can help mitigate these risks.

Another challenge is the quality of the finished surface. Achieving a smooth and even finish often requires intensive effort. Slight imperfections can impact both aesthetics and structural integrity. Using quality materials and keeping the formwork clean is essential. Inspecting the surfaces before the concrete sets is crucial. This step prevents costly repairs and delays.

Weather conditions can also pose difficulties. High temperatures might accelerate set times. Conversely, cold weather can slow down curing. Adjusting the pouring schedule based on environmental factors is necessary. Some teams overlook this detail and face unexpected setbacks. Being adaptable and aware of these challenges can make a notable difference in project success.

Related Posts

-

What is Flexible Formwork and How Can It Benefit Your Construction Projects

-

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

-

What is Plastic Construction Formwork and Its Benefits in Modern Building Projects?

-

How to Choose the Right Steel Formwork for Your Construction Project

-

How to Choose the Right Bracing Formwork for Your Construction Project

-

Why Bulkhead Formwork is Essential for Successful Construction Projects