Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

In the ever-evolving construction industry, the significance of effective beam slab formwork techniques cannot be overstated. A recent industry report published by the Construction Industry Institute indicates that improper formwork can account for up to 20% of project delays and cost overruns. As construction projects demand tighter schedules and greater budget control, mastering beam slab formwork techniques emerges as a crucial competency for professionals in the field.

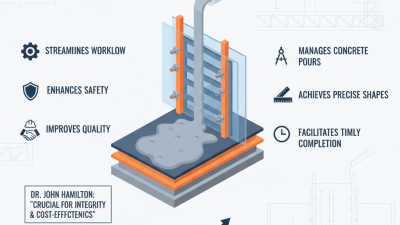

According to Dr. John Smith, a leading expert in concrete construction methods, "The efficiency of beam slab formwork directly impacts both the structural integrity of a project and its overall cost-effectiveness." This statement underscores the necessity for practitioners to be well-versed in best practices and innovative methods that ensure precision and safety in formwork application. With advancements in technology and materials, the methods surrounding beam slab formwork continue to improve, providing unique opportunities for enhancing productivity and performance in construction projects.

The goal of this guide is to illuminate the best practices and techniques in beam slab formwork, empowering industry stakeholders with the knowledge required to streamline their processes and mitigate risks. By harnessing these insights, construction professionals can not only elevate the quality of their work but also contribute to a more sustainable and efficient building environment.

Overview of Beam Slab Formwork Systems and Their Applications

Beam slab formwork systems are essential in modern construction, enabling the swift and efficient creation of a variety of structural elements. These systems are designed to provide the necessary support and shape for concrete beams and slabs during the curing process. Their applications range from residential buildings to large-scale commercial projects, reflecting their versatility and effectiveness in diverse construction contexts. The main advantage of using beam slab formwork lies in its ability to facilitate complex designs while maintaining structural integrity, ultimately leading to cost-effective project completion.

In practice, the choice of formwork system can significantly impact the overall workflow and quality of the finished structure. Options such as traditional timber forms, modular plastic systems, or advanced aluminum solutions offer different benefits depending on the specific requirements of a project. Factors such as load-bearing capacity, ease of assembly, and reusability must be considered when selecting the appropriate formwork system. Additionally, contemporary advancements in technology have led to innovative formwork solutions that enhance safety, reduce labor costs, and improve the adaptability of the system to various architectural designs, making them indispensable tools for construction professionals.

Key Materials Used in Beam Slab Formwork Construction

In beam slab formwork construction, selecting the right materials is critical to ensuring structural integrity and efficiency on site. Commonly used materials include plywood, steel, and aluminum, each offering distinct advantages. Plywood is favored for its versatility and lightweight nature, allowing for easy handling and adjustments during the installation process. Treated for moisture resistance, high-quality plywood can withstand the demanding conditions of concrete pouring, ensuring a smooth finish upon removal.

Steel formwork, on the other hand, provides exceptional durability and longevity, making it suitable for large-scale projects where repeated use is anticipated. Its stiffness and weight also allow for greater stability when pouring heavier concrete volumes. Additionally, lightweight aluminum formwork systems have gained popularity due to their ease of assembly and disassembly, leading to reduced labor costs. These systems often feature interlocking panels, which aid in achieving tight tolerances and smooth surfaces in the final product, enhancing both aesthetics and structural performance.

Integrating these materials thoughtfully not only improves construction timelines but also influences the overall cost-effectiveness of the project. By understanding the properties and applications of each material, construction professionals can optimize their beam slab formwork techniques, leading to better outcomes in their building projects.

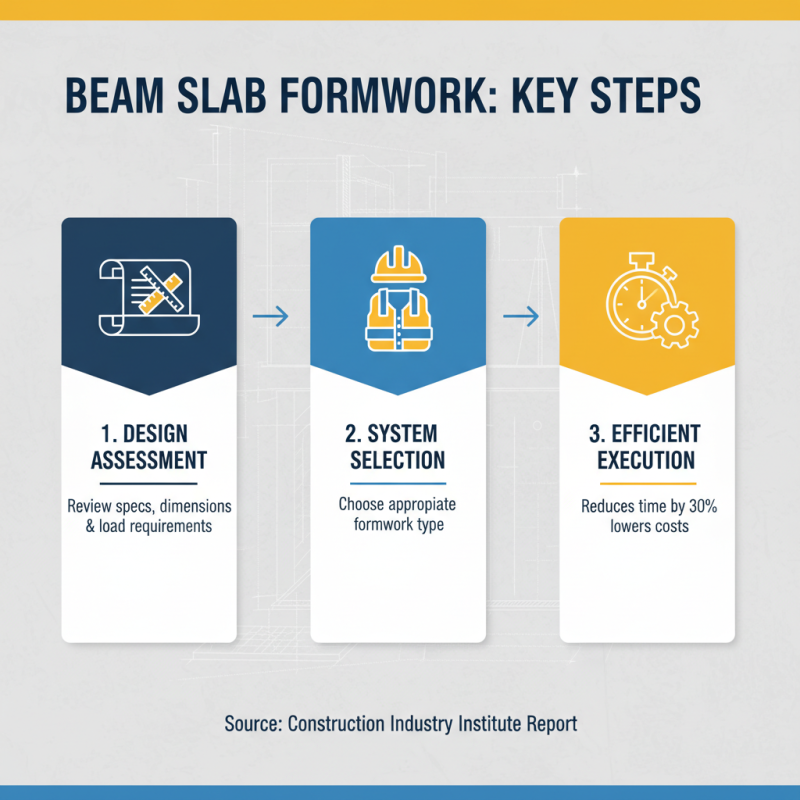

Step-by-Step Process for Setting Up Beam Slab Formwork

Setting up beam slab formwork requires careful planning and execution to ensure structural integrity and safety during construction. The first step in this process is to assess the design specifications and determine the appropriate formwork system based on the dimensions and load requirements. According to a recent report by the Construction Industry Institute, effective formwork can contribute to a reduction in construction time by up to 30%, ultimately lowering labor costs and improving project timelines.

Next, the placement of the formwork is crucial. Contractors should ensure that the base is level and properly supported to handle the weight of wet concrete. Using high-quality, durable materials is essential, as research shows that approximately 15% of construction failures can be attributed to inadequate or poorly maintained formwork. Once the formwork is secured, reinforcement bars should be placed as per the design requirements to enhance the beam slab’s strength. It is vital to continually inspect the setup for any potential flaws, as this can prevent costly repairs and project delays later in the construction phase. Following these step-by-step guidelines will result in a more efficient beam slab construction process that meets industry standards.

Safety Measures and Best Practices in Beam Slab Formwork

In beam slab formwork, ensuring safety is of utmost importance due to the inherent risks associated with construction work. First and foremost, it is essential to properly train all workers involved in the formwork process. This training should include the correct handling of materials and equipment, as well as understanding the potential hazards on-site. Regular safety drills and meetings can reinforce a culture of vigilance, emphasizing the importance of wearing personal protective equipment (PPE) such as helmets, gloves, and safety shoes.

Another crucial aspect of safety measures in beam slab formwork is the integrity of the formwork structure itself. Rigorous inspections should be conducted prior to placement of concrete to ensure that the formwork is adequately supported and can withstand the weight and pressure of the concrete. Adequate bracing, shoring, and use of high-quality materials are essential to prevent collapses. Furthermore, it is vital to monitor weather conditions and avoid working in adverse conditions that could compromise safety. Establishing clear communication channels among team members also plays a key role in enhancing safety, allowing for swift reporting and addressing of any concerns before they escalate.

Top 2025 Guide to Beam Slab Formwork Techniques and Best Practices

| Technique | Description | Safety Measures | Best Practices |

|---|---|---|---|

| Panel Formwork | Utilizes pre-fabricated panels for quick assembly. | Ensure panels are properly secured to prevent collapse. | Regularly inspect panels for damage. |

| Jump Formwork | Allows for vertical extension of formwork as construction progresses. | Use harnesses for workers on heights. | Plan lifting operations carefully. |

| Reusable Formwork | Enables multiple uses, reducing waste. | Inspect for wear after each use. | Maintain detailed records of formwork lifecycle. |

| Flying Formwork | Extends formwork out, allowing for large slabs. | Secure all attachments before use. | Coordinate with crane operators effectively. |

| Climbing Formwork | Used for structures that require vertical expansion. | Conduct stability tests before lifting. | Train crew on emergency procedures. |

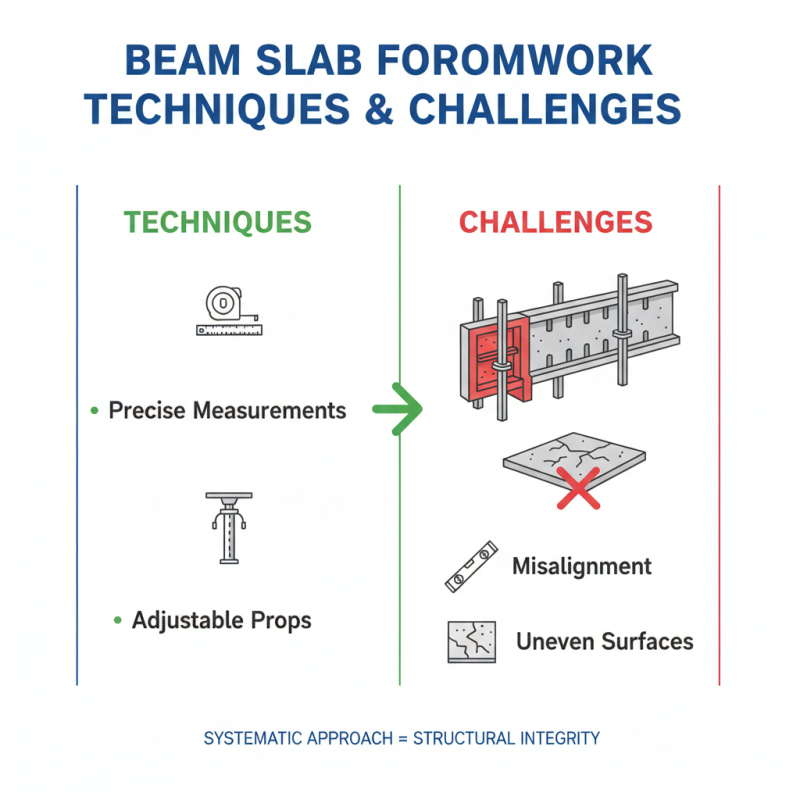

Common Challenges and Solutions in Beam Slab Formwork Techniques

Beam slab formwork techniques are essential in modern construction, allowing for the efficient support and shaping of concrete elements. However, builders often encounter common challenges throughout the process. One prevalent issue is the difficulty in ensuring proper alignment and support of the formwork. Misalignment can lead to uneven surfaces and structural issues once the concrete is poured. To mitigate this, adopting a systematic approach with precise measurements and utilizing adjustable props can help maintain the correct positioning during the installation phase.

Another challenge lies in the management of concrete pressure during the curing phase. As fresh concrete exerts significant pressure on the formwork, there is a risk of deformation or failure if the formwork is not robust enough. To combat this, using high-quality materials that can withstand the loads, along with implementing effective bracing systems, can enhance the stability of the formwork. Additionally, regular inspections during the pour can help identify any potential weaknesses early on, allowing for timely adjustments to prevent any structural mishaps. By addressing these challenges with comprehensive strategies, teams can improve their efficiency and outcomes in beam slab formwork projects.

Related Posts

-

Why Bulkhead Formwork is Essential for Successful Construction Projects

-

How to Choose the Right Steel Formwork for Your Construction Project

-

Top Benefits of Circular Formwork for Construction in 2025

-

How to Choose the Right Circular Column Formwork for Your Construction Project

-

Top 10 Things You Should Know About Formwork for Construction Projects

-

How to Choose the Best Precast Formwork for Your Construction Project